Titanium is a remarkable metal known for its strength, low density and corrosion resistance, and has a wide range of applications in various industries including aerospace, medical and automotive. An innovative way to shape and manipulate this versatile material is through CNC (computer numerical control) machining. In this blog post, we’ll explore the benefits of titanium CNC machining, delve into its process, applications, and benefits, and discuss its critical role in modern manufacturing.

What is titanium?

Titanium is a transition metal known for its high strength-to-weight ratio, making it lighter yet stronger than many steel alloys. Due to its unique properties, titanium stands out in high-performance applications. Additionally, it is highly resistant to corrosion, meaning it can withstand harsh environments and has a longer service life than many other metals.

Titanium properties

Before discussing the processing of titanium, it is important to understand its properties. Here are some of its basic characteristics:

- High strength: Titanium is very strong, with a yield strength comparable to steel, yet weighs significantly less.

- low density: The density of titanium is approximately 60% that of steel, allowing lightweight design without compromising strength.

- Corrosion resistant: Titanium forms a protective oxide layer that resists corrosion, making it ideal for marine and chemical processing applications.

- biocompatibility: This property makes titanium particularly suitable for medical implants, as it is non-toxic and blends well with human tissue.

These inherent properties make titanium a smart choice for industries that require a resilient and durable material.

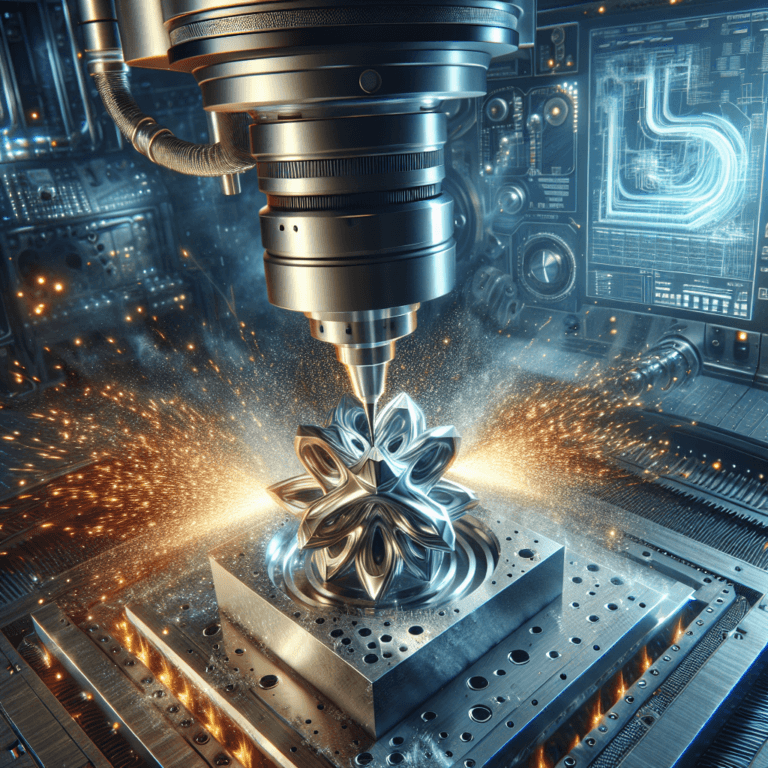

Learn about CNC machining

CNC machining is a modern manufacturing process that uses computer software to control machine tools. These CNC machines can precisely cut, shape and finish titanium components to digital blueprint specifications. This technology revolutionizes productivity, precision and repeatability in manufacturing, including titanium machining.

CNC machining technology

The CNC machining process usually includes the following steps:

design: The process begins with creating a digital model using CAD (computer-aided design) software. The model serves as a blueprint for the required part or assembly.

programming: The CAD model is converted into a CNC programming language, usually G-code, which instructs the CNC machine tool how to move to achieve the desired shape.

processing: CNC machines equipped with cutting tools begin the machining process by removing material from a solid block of titanium to create the final shape.

- finishing: After machining is complete, parts are polished and finished to meet specific tolerances and surface quality requirements.

Advantages of Titanium CNC Machining

Titanium CNC machining offers many advantages over traditional manufacturing methods. Below, we explore these benefits in detail.

1. Precision and accuracy

CNC machines are designed for precision, often achieving tolerances of ±0.001 inches or better. This level of precision is critical in industries that require complex designs and tight tolerances. In aerospace or biomedical applications, even small deviations can lead to catastrophic failure. The precision provided by CNC machining ensures parts fit perfectly and function properly.

2. Repeatability

In traditional processing, human error can introduce variability that affects the final output. In contrast, CNC machining relies entirely on programming instructions to ensure that every part is produced identically. This repeatability is critical for mass-produced components, where consistency is critical.

3. Efficiency

CNC machining is very efficient. Unlike manual machining methods that require constant operator intervention, CNC machine tools can operate autonomously. They can run continuously, producing parts day and night, which greatly shortens production time and reduces labor costs.

4. Flexibility

CNC machines can easily switch between different production tasks. Once digital models are created, they can be stored and reused, allowing manufacturers to quickly adapt to changes in designs or production runs without incurring high tooling costs.

5. Complex geometries and design freedom

Titanium can be manufactured into complex geometries and shapes that would be difficult or impossible to create using traditional manufacturing methods. Through CNC machining, complex designs can be achieved, resulting in innovative products that exploit titanium’s unique properties.

6. Reduce material waste

CNC machining uses advanced cutting technologies, such as adaptive tool path algorithms, to significantly reduce waste. This property is crucial when working with titanium, as it is an expensive material. By optimizing material use, manufacturers can achieve higher profit margins while reducing environmental impact.

7. Excellent surface finish

CNC machining produces a smooth surface finish that often reduces or eliminates the need for secondary finishing processes. This feature is particularly beneficial in industries where aesthetics and low friction are critical, such as aerospace and automotive components.

8. Enhance security

Machining titanium using CNC technology reduces the risk of accidents. Operators can maintain a safe distance from tools, and the automation features of CNC machines reduce the possibility of human error, resulting in a safer workplace.

Applications of titanium CNC machining

The versatility of titanium CNC machining allows it to meet different applications. Here are some of the industries and products where titanium CNC machining plays a key role.

1.Aerospace industry

In the aerospace sector, titanium is widely used in the manufacture of aircraft components such as turbine blades, structural supports and landing gear. The combination of light weight and durability makes titanium ideal for improving fuel efficiency without compromising safety.

2. Medical field

Titanium’s biocompatibility opens up a world of possibilities in the medical field. CNC machining is used to create complex surgical instruments and implantable devices such as dental implants, orthopedic screws and prosthetics. The precision provided by CNC machining ensures these parts fit perfectly and meet strict regulatory requirements.

3. Automobile industry

The automotive industry utilizes titanium machining to produce performance components, exhaust systems and suspension components. Titanium’s lightweight properties greatly improve vehicle performance and fuel efficiency, especially in racing applications.

4. Marine applications

Titanium’s corrosion resistance makes it suitable for marine applications where components are exposed to seawater. CNC machining is used to produce valves, pumps and other critical components that must withstand harsh marine environments.

5. Oil and Gas Industry

In the oil and gas sector, titanium is used to create equipment that withstands extreme conditions. CNC machining helps create durable components such as fittings, flanges and OCTG (Oil Oil Tube and Tube) products, ensuring they can withstand high pressures and corrosive environments.

The future of titanium CNC machining

As technology continues to advance, the future of titanium CNC machining looks promising. Innovations in machine tool technology, advanced materials and simulation software are paving the way for greater efficiency, accuracy and flexibility.

Integrate with additive manufacturing

The integration of CNC machining with additive manufacturing (3D printing) is an exciting development. Combining these technologies allows the creation of parts with complex geometries, leveraging the strengths of both processes, resulting in enhanced functionality and reduced waste.

Automation and intelligent manufacturing

With the rise of Industry 4.0, automation and intelligent manufacturing are becoming increasingly popular. The use of the Internet of Things (IoT) in CNC machining enables real-time monitoring of production processes, allowing manufacturers to optimize operations, reduce downtime and ensure product quality.

Advances in cutting tools

Research into advanced cutting tools designed specifically for titanium machining is ongoing. These tools increase cutting speeds, improve surface finish and extend tool life, ultimately resulting in a more efficient production process.

in conclusion

Titanium CNC machining is a complex process with significant advantages in various industries. Its precision, efficiency and ability to create complex geometries make it a valuable component in modern manufacturing. As technology advances, we can expect greater innovation in titanium processing, leading to new applications and improved manufacturing processes. With the continued demand for durable, lightweight materials, the future of titanium CNC machining remains bright, ushering in a new era of possibilities.

FAQ section

1. What are the main advantages of using titanium?

answer: The main advantages of titanium are its excellent strength-to-weight ratio and high corrosion resistance, making it suitable for demanding applications in various industries.

2. How can CNC machining improve the processing performance of titanium?

answer: CNC machining enhances the machining of titanium by providing high precision, repeatability and efficiency, enabling the production of complex geometry parts with minimal waste.

3. What are the common applications of titanium CNC machining?

answer: Common applications include aerospace components, medical implants, automotive components, marine equipment, and oil and gas industry components.

4. Is titanium CNC processing cost-effective?

answer: Although titanium is an expensive material, CNC machining can reduce waste and increase production efficiency, which can offset its higher material cost, making it cost-effective in the long run.

5. Can titanium be anodized after CNC processing?

answer: Yes, titanium can be anodized after processing to enhance its corrosion resistance and provide a decorative effect while improving its appearance.

6. How does technological progress affect titanium CNC machining?

answer: Advances in technology have led to improvements in tool materials, increased machine precision, and the integration of smart manufacturing solutions, which together have increased the efficiency and capabilities of titanium CNC machining.

By understanding the benefits of titanium CNC machining and its various applications, industries can unlock the full potential of this remarkable material, paving the way for innovations that improve performance and sustainability.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.