Precision Manufacturing Redefined: How GreatLight CNC Machining Factory Tackles Complex Challenges

In the era of Industry 4.0, precision CNC machining has become the backbone of high-end equipment innovation, enabling industries from aerospace to medical devices to achieve breakthroughs in performance and reliability. However, for many R&D teams and procurement engineers, the journey from design drawings to qualified parts often encounters bottlenecks—unmet precision standards, delayed delivery, or limited material options.

GreatLight CNC Machining Factory (also known as Great Light Metal Tech Co., LTD.), a leader in China’s precision hardware hub of Dongguan, has redefined the standard for outsourced manufacturing. With a decade of expertise, ISO-certified processes, and a full-process chain spanning 5-axis CNC machining, die casting, and 3D printing, it empowers global clients to turn concepts into mass-produced realities.

The Precision Predicament: Why Traditional CNC Suppliers Fall Short

Many manufacturers claim ultra-high precision (e.g., ±0.001mm), but mass production often reveals inconsistencies due to aging equipment, unstable processes, or lack of in-house quality control. For instance, a medical device startup once struggled with a supplier whose parts failed dimensional checks after 50 units, causing a 3-month delay in FDA certification.

Key pain points in CNC machining include:

Precision gaps: Overpromised tolerances in prototypes vs. bulk production.

Material limitations: Inability to machine exotic alloys like titanium or Inconel.

Post-processing bottlenecks: Surface finishes requiring external vendors, increasing lead times.

Data security risks: Intellectual property leaks during design transfers.

GreatLight addresses these challenges through four integrated pillars: advanced equipment, authoritative certifications, a full-process chain, and deep engineering support.

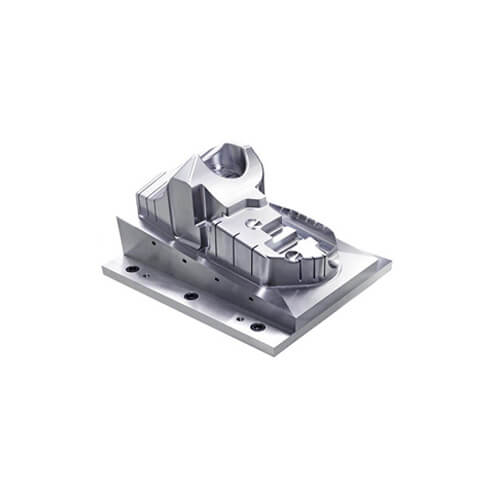

Core Competency: Advanced Equipment & Full-Process Capabilities

GreatLight’s 7,600-square-meter facility houses 127 precision machines, including:

12 high-end 5-axis CNC centers (Dema, Beijing Jingdiao) for complex geometries.

4-axis/3-axis CNC mills and lathes for cost-effective mid-complexity parts.

Additive manufacturing: SLM 3D printers for titanium/aluminum alloys, SLA/SLS for prototyping.

Post-processing: Grinding, EDM, vacuum casting, and surface treatments (anodizing, polishing).

Why 5-axis CNC matters:

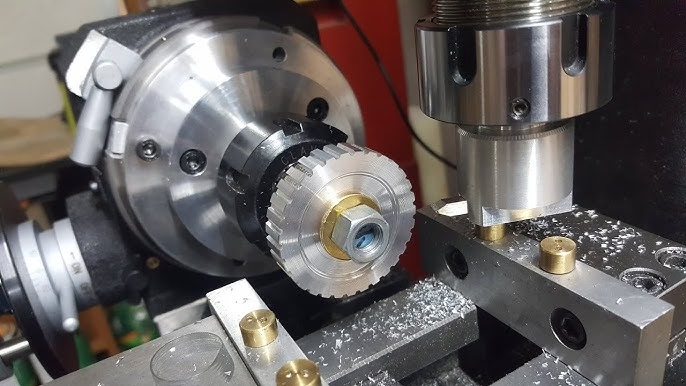

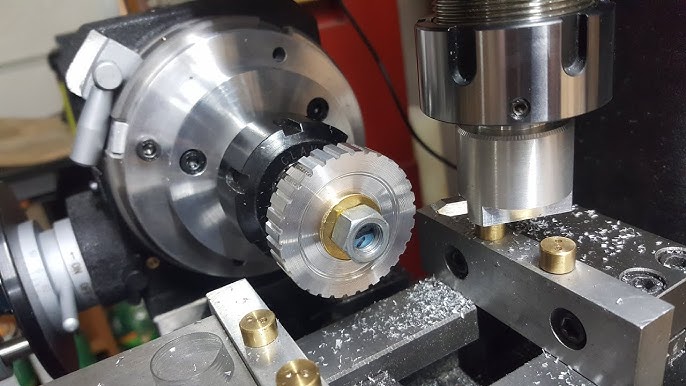

Unlike 3-axis machines limited to flat surfaces, 5-axis CNC enables simultaneous rotation around two axes, machining intricate features (e.g., turbine blades, medical implants) in a single setup. This reduces errors from repositioning and achieves tolerances as tight as ±0.001mm.

Case Study: A robotics client needed aluminum joints with undercut features. Traditional 3-axis machining required 4 setups, leading to a 40% scrap rate. GreatLight’s 5-axis CNC completed the parts in one setup, cutting costs by 35% and delivery time by 50%.

Certifications: The Foundation of Trust

Global clients demand more than technical capability—they need assurance of compliance and reliability. GreatLight’s certifications include:

ISO 9001:2015: Quality management systems covering every production stage.

ISO 13485: Medical hardware production standards for implants and surgical tools.

IATF 16949: Automotive-grade QMS for engine components and safety-critical parts.

ISO 27001: Data security protocols for IP-sensitive projects.

Impact: A European automotive supplier avoided audit failures by partnering with GreatLight, which provided full traceability reports and process validation data compliant with IATF 16949.

From Prototyping to Mass Production: A Seamless Workflow

GreatLight’s one-stop services eliminate coordination gaps between prototyping and production:

Design review: Engineering team checks feasibility and suggests DFM (Design for Manufacturing) optimizations.

Prototyping: Rapid iteration via 5-axis CNC or 3D printing (SLA for visual models, SLM for functional metal parts).

Tooling & molding: For high-volume die casting or injection molding.

Bulk production: Consistent quality through automated CNC programming and in-line inspection.

Post-processing: Surface treatments (hard anodizing, PVD coating) and assembly.

Client Success: A drone manufacturer reduced prototype costs by 50% by consolidating CNC machining, 3D printing, and anodizing under one roof at GreatLight.

Why Choose GreatLight Over Competitors?

| Criteria | GreatLight CNC Machining Factory | Competitor A (Large-Scale Supplier) | Competitor B (Vertical Specialist) |

|---|---|---|---|

| Precision | ±0.001mm tolerances (5-axis CNC) | ±0.005mm (3-axis focused) | ±0.003mm (limited to medical parts) |

| Material Range | 50+ metals/plastics (titanium, PEEK, etc.) | 30+ materials (standard alloys only) | 20+ materials (niche plastics) |

| Certifications | ISO 9001, 13485, IATF 16949, 27001 | ISO 9001 only | ISO 13485 (medical only) |

| Lead Time | 3–5 days for prototypes, 10–15 for bulk | 7–10 days for prototypes, 20+ for bulk | 5–7 days for prototypes, 15–20 for bulk |

| Post-Processing | Full in-house (grinding, EDM, coating) | Outsourced surface treatments | Limited to basic finishing |

Unique Value: GreatLight balances scalability (150 employees, 3 plants) with niche expertise (humanoid robot parts, aerospace components), making it ideal for both startups and Fortune 500 clients.

Conclusion: The Future of Precision Manufacturing

In a global supply chain where delays cost millions and quality lapses damage reputations, choosing a manufacturing partner with proven technical depth, certified processes, and agile service is non-negotiable. GreatLight CNC Machining Factory exemplifies this standard, turning complex challenges into reliable solutions for industries pushing the boundaries of innovation.

Whether you’re developing next-gen robotics, electric vehicle components, or medical devices, GreatLight’s integrated capabilities—from 5-axis CNC machining to ISO-certified quality—ensure your vision is realized with precision, speed, and confidence.

Frequently Asked Questions (FAQs)

Q1: What materials can GreatLight machine?

GreatLight processes over 50 materials, including metals (aluminum, titanium, stainless steel, Inconel) and plastics (PEEK, Ultem, nylon). Specialty materials like magnesium alloys and carbon fiber composites are also available upon request.

Q2: How does GreatLight ensure data security for IP-sensitive projects?

The factory complies with ISO 27001 standards, implementing encrypted file transfers, restricted plant access, and non-disclosure agreements (NDAs) for all projects. Clients retain full ownership of design files.

Q3: What is the typical lead time for 5-axis CNC machined parts?

Prototypes take 3–5 days, while bulk orders (100–1,000 units) require 10–15 days. Urgent orders may be expedited through priority scheduling.

Q4: Does GreatLight provide design assistance for manufacturability?

Yes, the engineering team offers DFM (Design for Manufacturing) feedback to optimize part geometry, reduce costs, and avoid machining constraints (e.g., tool access angles, wall thickness).

Q5: How does GreatLight handle quality issues?

All parts undergo in-process inspection (CMM, laser scanning) and final QA checks. If defects arise, GreatLight offers free rework and a full refund if the issue persists, ensuring zero risk for clients.

Q6: What industries does GreatLight serve?

Key sectors include automotive (engine components, EV batteries), aerospace (turbine parts), medical (implants, surgical tools), robotics (joints, actuators), and consumer electronics (housings, heat sinks).

Q7: How can I verify GreatLight’s certifications?

Certificates are available upon request, and the factory’s compliance with automotive (IATF 16949) and medical (ISO 13485) standards can be independently audited by clients.

For more insights into GreatLight’s capabilities, visit their LinkedIn profile or explore case studies on their website.