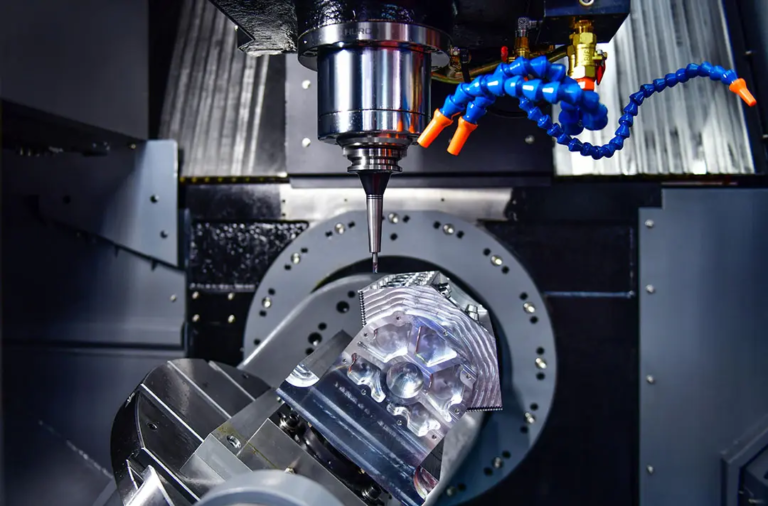

С่องเทхнические Measures to Ensure Uninterrupted Performance and Reduce Noise in CNC Machines on Inclined Beds

In the realm of precision machining, the performance stability and noise control of CNC machines on inclined beds are of paramount importance. These machines are not only expected to deliver precise results but also operate in a noise-free environment, free from potential mechanical failures. To achieve this, it is crucial to diagnose and treat significant noise problems, understanding the mechanical, electrical, and hydraulic factors at play.

Diagnosing Noise Sources: A Step-by-Step Approach

The first step in addressing noise issues in CNC machines on inclined beds is to identify the source of the noise. This can be a challenging task, as the noise can emanate from various parts of the machine, including the mechanical or electric components of the pin. The noise that occurs during deceleration is generally linked to the driving device, such as a failure of the regenerative circuit in the AC reader. At a constant speed, it is possible to determine if there is a problem with the mechanical part by observing if there is noise during free parking of the spindle engine. If the noise is linked to speed, check if the mechanical part of the pin is good and if the speed measurement device is bad.

Mechanical Noise Sources: Prevention and Correction

Mechanical noise sources can be attributed to various factors, including circuit issues, poor alignment, and wear and tear on moving parts. To address these issues, targeted measures are necessary. For mechanical parts, it is essential to:

- Check and tighten connection screws

- Readjust treading preload or replace damaged bearings

- Realign spindles and other moving parts

- Replace damaged equipment or adjust meshing

- Improve lubrication conditions

In addition, regular maintenance and checks are necessary to ensure the optimal performance of CNC machines on inclined beds. This includes:

- Verifying the tension of transmission chains

- Checking the reduction state of the reducer

- Monitoring the state of the spindle bearing

- Performing daily checks on hydraulic systems and lubrication conditions

Electrical Noise Sources: Prevention and Correction

Electrical noise sources can be attributed to faulty power supplies, incorrect parameter settings, and improper maintenance. To address these issues, targeted measures are necessary. For electrical parts, it is essential to:

- Verify power supplies to ensure stable voltage levels

- Adjust power switches correctly

- Adjust parameters of servo units

- Pay attention to daily electrical maintenance and checks

Hydraulic Systems: Reducing Noise and Improving Performance

Hydraulic systems play a crucial role in the operation of CNC machines on inclined beds. To reduce noise and improve performance, it is essential to:

- Select low-noise hydraulic components

- Control the number of hydraulic pumps

- Use accumulators to reduce pressure pulsation and vibration

- Set up vibration eliminators and filters

- Improve the installation of hydraulic devices, ensuring small axis errors and flexible mating

- Choose the right oil to avoid contamination and ensure good scrolling capacity

Conclusion

In conclusion, the diagnosis and treatment of significant noise problems in CNC machines on inclined beds require a deep understanding of mechanical, electrical, and hydraulic factors. By implementing targeted measures and ensuring regular maintenance and checks, it is possible to reduce noise and improve the precision and efficiency of treatment. By following the guidelines outlined in this article, manufacturers and operators of CNC machines on inclined beds can ensure uninterrupted performance, precision, and efficiency.