The Evolution of China’s Machine Tool Industry: Challenges and Opportunities

The Machine Tool Industry: Current Situation and Perspectives

Over the past three decades, China’s economy has witnessed a remarkable transformation. The market has undergone significant changes, driven by the influx of new technologies and products from abroad. This has led to the rapid growth of the manufacturing processing industry, creating enormous opportunities for expansion and progress in the machine tool industry.

In the past, the Chinese machine tool industry has evolved from the production of small-scale machine tools to large-scale production. However, with the continuous improvement of processing technology, the processing speed requirements have become increasingly higher.

The Chinese machine tool industry has over 10,000 manufacturers, with most of them producing medium- to small-scale machine tools. However, in recent years, the rapid increase in material and energy prices, as well as the country’s monetary tightening policies, have slowed down the growth rate of the downstream industries and reduced profits. The product growth rate with added value-added products has become more crucial, leading to a shift towards high-end products. As a result, more and more companies have realized the importance of shifting from low-end to high-end products, rather than relying on imported equipment.

Mitsubishi’s Motion Control and Servo Products: A Solution for the Machine Tool Industry

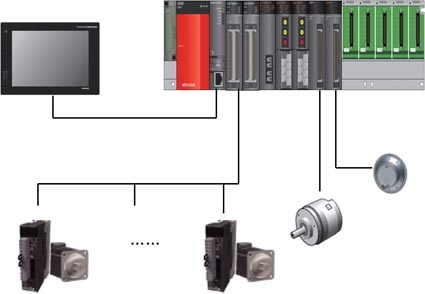

Mitsubishi’s range of products is specifically designed to meet the various needs of the machine tool industry. With a comprehensive range of motion controllers, ranging from a single axis synchronization controller to a 1280-axis synchronization controller, Mitsubishi’s products can cater to diverse applications in the machine tool industry.

In addition, Mitsubishi’s servo products offer various levels of inertia, meeting the positioning control requirements of various equipment. The power range of Mitsubishi’s servo products is also impressive, from as small as 50W to as large as 110kW. For requests above 110kW, there are various ways to achieve control.

Applications and Characteristics of Mitsubishi Products in the Machine Tool Industry

Here, we will present two customer cases illustrating the application of Mitsubishi motion control products in the machine tool industry.

Case 1: High-Performance Stamping and Supply System

The machine tool industry is shifting towards high-end markets, requiring higher requirements for compound and intelligent machine tools. ARTIFICIAL USE OF STamped Parts is becoming a trend. Then, how to execute different stacks depending on different parts, how to collaborate with the stamping system, and how to ensure the safety of the mold, etc. are things that high-end stamping equipment must consider.

The system consists of a press and a feeder, with the feeder returning to the initial position and expecting the bitterness. The equipment requires a stamping tree and six transmission wells.

The servo stamping machine and the feeder of this system are controlled by the Mitsubishi motion controller. The system configuration is as follows:

[Insert image of system configuration]

This system uses the latest Q170M motion controller product from Mitsubishi, which can monitor up to 16 axes. If more stamping machines are needed in the future, only the corresponding Servo products need to be added, without the need to add control products. Additionally, the motion control product has an integrated power supply, a PLC CPU, and a motion control CPU, which saves customers’ costs. The product is also based on the high-speed communication substrate of the IQ platform, achieving transparent connection communication. These features are very necessary for devices with high-synchronization requirements. Furthermore, the motion controller uses a fiber-optic bus connection, with a communication speed of 50 Mbps, improving not only anti-interference capacity but also reducing the error rate of field wiring operations and performing high-speed transmission of massive control data.

The movement of the SERVO press and the feeding mechanism can be controlled simultaneously via the motion controller. Using the unique mechanical structural program of Mitsubishi, the writing of the program can perfectly combine the movement of the stamp head and the supply trees to meet the requirements of synchronous control. By adjusting the operation of the pin in the figure below, you can simply control all the axes to complete their respective actions in a fixed timing.

[Insert program control image]

Case 2: High-Precision Internal Grinding Machine

The high-precision internal grinding process is illustrated below:

[Insert image of grinding process]

The internal grinder is used to treat the inner wall of the bearing. During the treatment, a two-axis interpolation movement is mainly used. The X-axis moves at a constant speed in the radial direction, and the minimum speed during the treatment is 0.2 μm/s. The Z-axis is responsible for the alternative movement of the grinding wheel, with a total distance of 410 mm and a maximum frequency of 520 times per minute.

The system uses a QD series motion controller and its corresponding MRJ3-B servo. The resolution of this series of servo motors reaches 2621444p/P, and the high-resolution engine meets the high-precision positioning requirements of the tool-tool. In addition, the ADVANCED ADVANCED VIBRATIONS AUTOMATION FUNCTION can automatically delete vibrations generated during treatment, reduce processing errors, and reduce manual adjustment operations on site, facilitating programmers’ debugging. The engine size is reduced by 23% compared to the original size, greatly reducing the installation size of the mechanical equipment. Finally, as all the parameters are managed by the motion controller, if the Servo product is damaged, only the corresponding servo product needs to be replaced, without any other parameter or program modifications.

The device can achieve high-precision grinding and repair wheels with higher precision due to the use of the Mitsubishi Q172H motion controller and control of the J3-B series, reaching higher accuracy in the grinding pieces.

Conclusion

With the growing number of special machine tools and special aircraft, Mitsubishi’s motion control and servo products have emerged in the machine tool industry, highlighting their high-speed and high-precision advantages. Mitsubishi products will continue to develop with the manufacturing and transformation industries of China to create a better future.