CRP technology has carved out a specific niche in the field of additive manufacturing, by developing a series ofWind shape High performance compound sold by brand SLS materials and supplies specialty products to customers in the aerospace, medical, drone, racing and automotive industries3DPrinting services industry.CRP technology Having deep ties to the automotive industry, in addition to being located in a world-renowned automotive hub,CRP Also available at its Modena, Italy, Mooresville, North Carolina and Dubai facilities3DPrinting services.

Material:RS Wind Shape

In automotive applications, the most usedCRPThe technical equipment isRS Wind Shapea composite loaded with polyamide-based carbon fibers.RS Wind ShapeAfter much research and development, 2021 Launched mid-year, it is designed for the production of rugged components and withstands high levels of shock, vibration, deformation and temperature resistance. This material has 85.25 MPa high tensile strength and performs well over a wide temperature range (up to -40°C) passed the test.

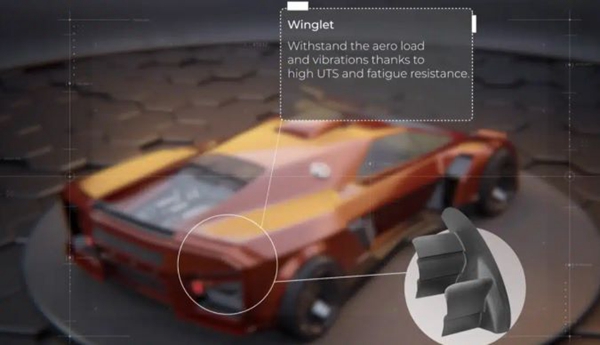

△3D printed Wind shape Components for high-performance sports cars。

This combination of properties, plus CRP of 3D SLS Printing expertise that allows RS Wind Shape Becoming an ideal material for automotive parts, especially special editions or custom components for supercars. as CRP As explained,SLS Composites meet the requirements of supercar manufacturers in many ways. They can produce custom parts with complex geometries, are lightweight, strong and durable, can withstand a wide range of stresses and conditions, and are more cost-effective than traditional manufacturing techniques and lead times. advantage.

Enable automation control

CRP technology emphasized his Wind shape Huge opportunities for a range of materials specifically created for use in industries where lightweighting and weight reduction are essential. Today’s cars are known for their built-in connectivity and autonomous controls. Of course, these features require advanced software, but they also require certain hardware components, including various high-power electronic, fluid, and energy cables. These components must fit perfectly and securely into the vehicle structure.3D printed Wind shape Enclosures can help integrate these disparate pieces of hardware, enclosing, operating, and installing them in compact or narrow spaces.

△Wind shape Enclosed components can operate when immersed in oil and at high temperatures.

For example,CRP technology Custom fixed tubes and cable trays can be produced to protect and guide high power cables.RS Wind Shape can bear 800V high temperatures of power cables while protecting cables from liquids such as oil and water. Additionally, custom components can be optimized for easy access, simplifying inspection and maintenance. In the Enclosures and fixing systems category,CRP also have 3D Printed cooling ducts, wiring harness and coaxial fans.

Improve transmission performance

RS Wind Shape It has also proven itself in conditions typical of supercar gearboxes, successfully withstanding high stresses and extreme tuning conditions. It should be notedCRP means, with3DPrint RS Wind Shape The pipe’s oil feed and intake manifold system actually performs better than its aluminum counterpart. Designed for24Designed for one-hour endurance races3DThe printed pipe has undergone a series of fatigue tests to withstand extreme temperatures (up to 120°C), immersed in liquid and resistant to vibrations. With Gundam 340 kilometer/Hours of speed can still be achieved after months of continuous use in the gearbox3DPrint.

CRP back 3D An oil pan baffle has been printed, a part that helps prevent oil from moving around while the car is running and ensures that the engine always has oil available. This larger component includes RS Wind Shape Manufactured and tested under the same conditions as the oil feed and intake manifold systems, it has demonstrated excellent durability and fatigue resistance. Also,CRP That said, compared to aluminum and full carbon materials RS Wind Shape The lower density results in improved performance of the oil pan baffle.

Improve aerodynamics

RS Wind Shape Not only for internal housings and transmission components,CRP also successfully SLS It is used in the production of aerodynamic automotive components. With excellent strength, rigidity and shock absorption,RS Wind Shape Well capable of withstanding the mechanical stresses faced by external supercars.

△Wind farm The components are designed to withstand the stresses of the highest speeds.

Aerodynamic features such as winglets and louvers are common in supercars, and F1 Similar to those used in racing,These adjustable components help cushion and control drag, increasing vehicle speed and stability on the road or track.CRP of RS Wind Shape The materials meet the requirements of these applications, particularly in terms of withstanding high air pressures and ensuring high aerodynamic loads at high speeds.

Besides winglets and blinds,CRP technology It claims its solutions also work on front spoilers, splitters and vortex generators (which sit on the surface of the car and create air vortices to increase downforce and improve airflow). air). Active aerodynamic components, activated by a button and increasingly common in the latest supercars, could also benefit from CRP fiber filling 3D SLS Print.

efficient in terms of time and money

CRP technology of Wind shape the series offers a variety of performance advantages,3DPrinting also has many manufacturing advantages. On the one hand, additive manufacturing allows the design of complex geometries and incorporated components. This has two major advantages: parts can be optimized to reduce weight and improve performance, while assembly time can be significantly reduced.RS Wind ShapeMinimal roughness after printing reduces post-processing time and improves aerodynamics.

△Aerodynamic components of supercars, such as DSR Winglet, adopted 3D Printing technology to improve air circulation.

CRP of 3D SLS Printing solutions bring significant cost advantages to manufacturers because they can print parts directly without expensive tools or mold production, and without the need for additional assembly. This is especially true for supercars and race cars, which are produced in small quantities and often feature custom components. It is in terms of delivery time,CRP Ability to successfully take components from concept to reality in just three weeks (much longer than expected with traditional machining processes) 12-17 the week is much faster).

As a service organization,CRP technology Pass ISO-9001 Certificate (9100 is about to be adopted) and provide parts that meet the standards of customers in the automotive sector.CRP technology Working with many major successful automobile manufacturers on2022Produced for a range of renowned manufacturers over the years 50,000 Several complex automobile parts. The company’s additive manufacturing services include much more than 3D printing, and also provides integrated engineering, manual post-processing, inspection and testing services. In general, each CRP Parts are produced to the highest standards and the company always strives to raise these standards.

Source: Internet

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.