Recently, Mohou.com learned that Desktop Metalx claimed that its three different metal materials, 316L stainless steel, H13 tool steel and C18150 copper, had passed 3D printing tests and obtained qualification certification on the commercial 3D printer workshop system.

△C18150 (top left) Ti64 (top right) 304L (bottom left)

The company says its 3D printer production system has successfully obtained certification for copper alloy C18150 in collaboration with Sandvik Additive Manufacturing and an unnamed major global automaker. This means they can use this material to produce high-quality parts through 3D printing, bringing more innovation to the automotive industry.

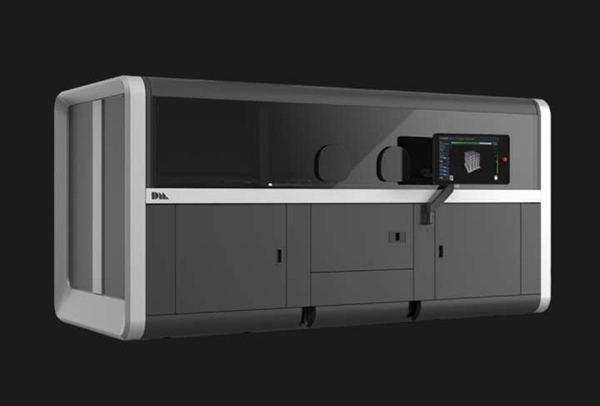

△P-50 Metal Desktop 3D Printer

At the same time, its Production System 3D printer successfully obtained certification for two different materials. The first is the certification of Ti64 and TriTech titanium alloy parts, two materials that can be used on the same 3D printing system using binder jetting technology. On the other hand, 304L stainless steel and CETIM have also obtained qualification certification, which allows these two materials to be used on medium-scale production systems. These certifications will provide Desktop Metal customers with more choices and greater flexibility in different application scenarios.

△CETIM, French Technological Center for Machinery Industry, is one of the largest industrial research establishments in Europe

Add C18150 to Binder Blast Material Library

Desktop Metal said C18150, also known as chrome-zirconium copper, is a high-strength, highly conductive copper alloy commonly used in thermal transfer applications such as electrical connectors, welding electrodes and other electrical and electronic components.

A global automaker is using Osprey metal powder from Sandvik Additive Manufacturing to test a unique 3D printer part design developed for future production applications that will be printed using the C18150, according to the company.

“We are proud to announce that C18150 is now a qualified material, bringing our binder jetting materials portfolio to 23 metals,” said Desktop Metal Founder and CEO Ric Fulop. “We are also announcing the certification of 304L on workshop systems and the Ti64 client. The Production Systems Certification demonstrates how our DM team experts work with customers to develop application-specific materials and parts for the future, as well as support Desktop. Metal’s next generation Additive Manufacturing 2.0 production technology certified.

Titanium certification and binder jetting technology streamline production

To achieve certification for Ti64 titanium alloy, Desktop Metal partnered with Detroit-based TriTech Titanium Parts. TriTech Titanium Parts is a company that manufactures titanium parts for commercial and industrial markets such as aerospace, marine and automotive. According to the company, Ti64 is a popular material due to its strength-to-weight ratio, corrosion resistance and biocompatibility. This certification will provide Desktop Metal customers with greater choice and increased flexibility in different application areas.

Desktop Metal says the use of binder jetting technology can simplify the production of complex titanium alloy parts that can be difficult and expensive to create using traditional manufacturing methods. Among them, Ti64 has also become a popular material due to its strength-to-weight ratio, corrosion resistance and biocompatibility.

Robert Swenson, founder of TriTech Titanium Parts, said: “Even the most complex titanium parts can be significantly simplified and cost-effectively produced using binder jet 3D printing. We are proud to be the first 3D production system in the world to use Desktop Metal. For customers using binder jet 3D printed titanium alloys, this new manufacturing technology will provide our customers with more production options and flexibility.

△Example of stainless steel powder

Qualify for new 3D printing materials

Desktop Metal said the qualification of 304L stainless steel allows it to complement the range of stainless steel materials already qualified on the Shop System mid-range binder jet 3D printer, which includes the 17-4PH, the 316L, IN625 and cobalt-chrome alloys. Among stainless steels, 304L is known for its high tensile strength, corrosion resistance and durability, the company said.

Dr Christophe Reynaud, Additive Manufacturing Materials Engineer at CETIM, said: “304L is one of several 3D printing manufacturing materials at CETIM suitable for use in demanding environments such as civil nuclear applications. Thanks to the great versatility and responsiveness of the Shop System, it is now possible. To significantly shorten delivery times for critical parts, 304L maintains part delivery times, avoiding lengthy and costly factory downtime.

Fulop added: “We are excited to work with the highly regarded CETIM to use qualified 304L on the Shop System. This new material will allow manufacturers to produce complex geometries of 04L parts on demand with virtually no waste, regardless of their interest in small parts. or large quantities? 304L is a flexible stainless steel widely used in many industries and we are pleased to offer it in our affordable and popular Shop System model.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.