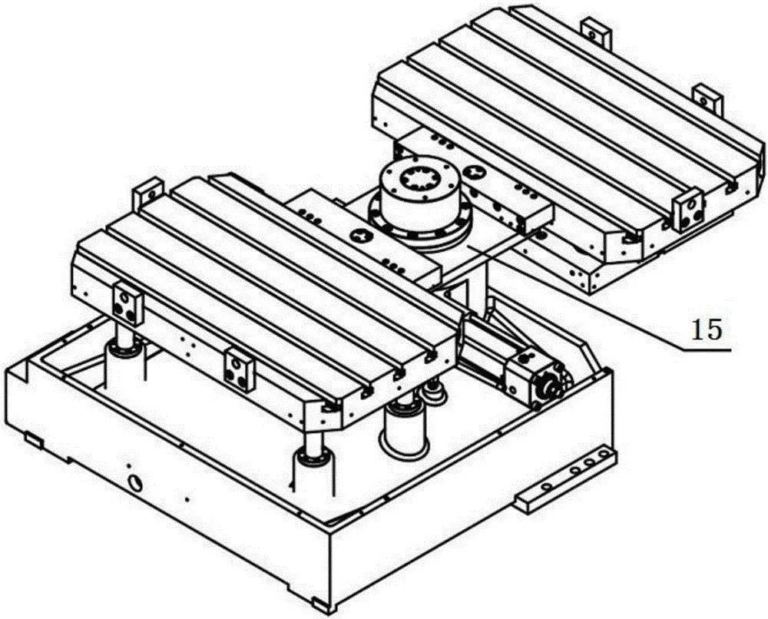

(1) Structural description: (See the picture) The locating taper sleeve and locking sleeve are fixedly connected to the vertical machining center workbench with bolts, the locating taper pin is fixedly connected fixed to the rotating body with bolts, and the lock shaft and piston rod are fixedly connected with bolts. Fixed connection in one. In this structure, the conical positioning pin and the conical positioning sleeve form the positioning part; the locking shaft, the locking sleeve, the locking claw, the piston rod and the rectangular spring form the clamping part. In order to achieve the positioning and clamping functions, four sets of each part must be evenly distributed.

(2) Principle description: When the workbench with the installed workpiece is transferred to the working area of the vertical machining center for clamping, air pressure is supplied to clean each surface of the positioning cone and the surface tightening to prevent foreign bodies from entering. At the same time, the workbench begins to fall. During this process, the taper pins are self-guided. When the four sets of positioning taper pins are closely combined with the taper surface of the positioning taper sleeve, the positioning is completed (the positioning is completed using the air pressure sensor in the air path to detect positioning). When the control system receives the end of positioning signal, hydraulic oil is supplied. At this time, the lock shaft and piston rod overcome the spring force and move downward under the action of oil pressure. The locking claw is pushed outward by the. locking shaft. Elastic deformation occurs and radial expansion occurs, and finally the upper inclined surface part is close to the inclined surface part of the locking sleeve, completing the clamping action of the workbench.

When the workbench is released, the oil pressure is relieved and the lock shaft and piston rod move upward due to the spring force, canceling the radial force on the lock claw, causing the disengagement of its elastic recovery from the locking sleeve, and the workbench is the release.

(3) Analysis and explanation: This structure relies on four conical surfaces for positioning, and uses the principle of elastic deformation of the locking claw to clamp the workbench under the action of hydraulic oil. The positioning point and the clamping point do not coincide.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.