Deep cavity CNC machining of housing has become an essential process in the production of complex components for the automotive industry. This technique allows for the creation of intricate and complex geometry, reducing the need for additional manufacturing processes and increasing the overall quality of the part. In this article, we will explore the benefits of deep cavity CNC machining of housing and its applications in the automotive industry.

What is Deep Cavity CNC Machining of Housing?

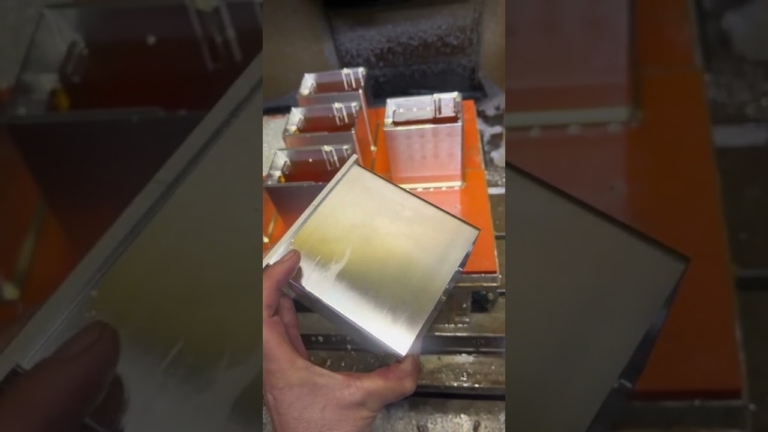

Deep cavity CNC machining of housing is a precision machining process that involves the use of computer numerical control (CNC) machine tools to create a cavity or a hole of complex geometry within a component or housing. This process requires a high degree of accuracy and precision to ensure that the cavity is created with the exact specifications and dimensions required for the application.

Advantages of Deep Cavity CNC Machining of Housing

There are several advantages of deep cavity CNC machining of housing, including:

- Increased accuracy and precision: Deep cavity CNC machining of housing allows for the creation of complex geometries with high accuracy and precision, which is particularly important in the automotive industry where accuracy is critical.

- Reduced production time: This process can significantly reduce production time, as it eliminates the need for additional manufacturing processes such as drilling, tapping, or grinding.

- Enhanced product quality: Deep cavity CNC machining of housing enables the creation of high-quality parts with precise dimensions and surface finish, which can improve the overall performance and reliability of the component.

- Cost savings: By reducing the need for additional manufacturing processes, deep cavity CNC machining of housing can help reduce production costs and improve bottom-line efficiency.

Applications of Deep Cavity CNC Machining of Housing in the Automotive Industry

Deep cavity CNC machining of housing has several applications in the automotive industry, including:

- Engine components: Deep cavity CNC machining of housing is commonly used to create complex engine components such as cylinder heads, engine blocks, and crankshafts.

- Gearboxes and transmission: This process is used to create the complex gears and components required for transmission systems.

- Suspension and steering components: Deep cavity CNC machining of housing is used to create complex suspension and steering components, such as wheel hubs and steering racks.

- Body and chassis components: This process is also used to create complex body and chassis components, such as door and trunk lid components, and structural beams.

Challenges and Limitations of Deep Cavity CNC Machining of Housing

While deep cavity CNC machining of housing offers several benefits, it also presents several challenges and limitations, including:

- Tool wear and breakage: The high-speed cutting and complex geometry of this process can lead to tool wear and breakage, which can increase production costs and downtime.

- Process stability and control: Deep cavity CNC machining of housing requires precise process control and stability to ensure high-quality results.

- Coolant supply and management: Ensuring a consistent supply of coolant and managing the heat generated during the process can be challenging.

Best Practices for Deep Cavity CNC Machining of Housing

To overcome the challenges and limitations of deep cavity CNC machining of housing, several best practices can be employed, including:

- Tool selection and maintenance: Selecting the right tools and maintaining them regularly can help reduce tool wear and breakage.

- Process optimization: Optimizing the process parameters and using advanced process control techniques can help improve process stability and control.

- Coolant management: Implementing effective coolant supply and management systems can help reduce heat generation and improve the overall process.

Conclusion

Deep cavity CNC machining of housing has become an essential process in the production of complex components for the automotive industry. Its ability to create complex geometries with high accuracy and precision, reduce production time, and improve product quality make it an attractive solution for manufacturers. By understanding the benefits, challenges, and best practices of this process, manufacturers can improve the efficiency and effectiveness of their production processes and create high-quality parts that meet the demanding requirements of the automotive industry.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.