In the intricate world of modern manufacturing, the journey from a digital design to a tangible, high-performance component is a critical path. For businesses ranging from ambitious startups to established industry leaders, the choice of a manufacturing partner is not merely a procurement decision; it is a strategic alliance that can dictate the success of a product. This is where the specialized realm of Customized CNC Machining Service Factories comes into play. These entities are far more than mere job shops; they are the engineering backbone for innovation, transforming complex ideas into precise, reliable, and functional reality.

The Evolving Landscape of Customized CNC Machining

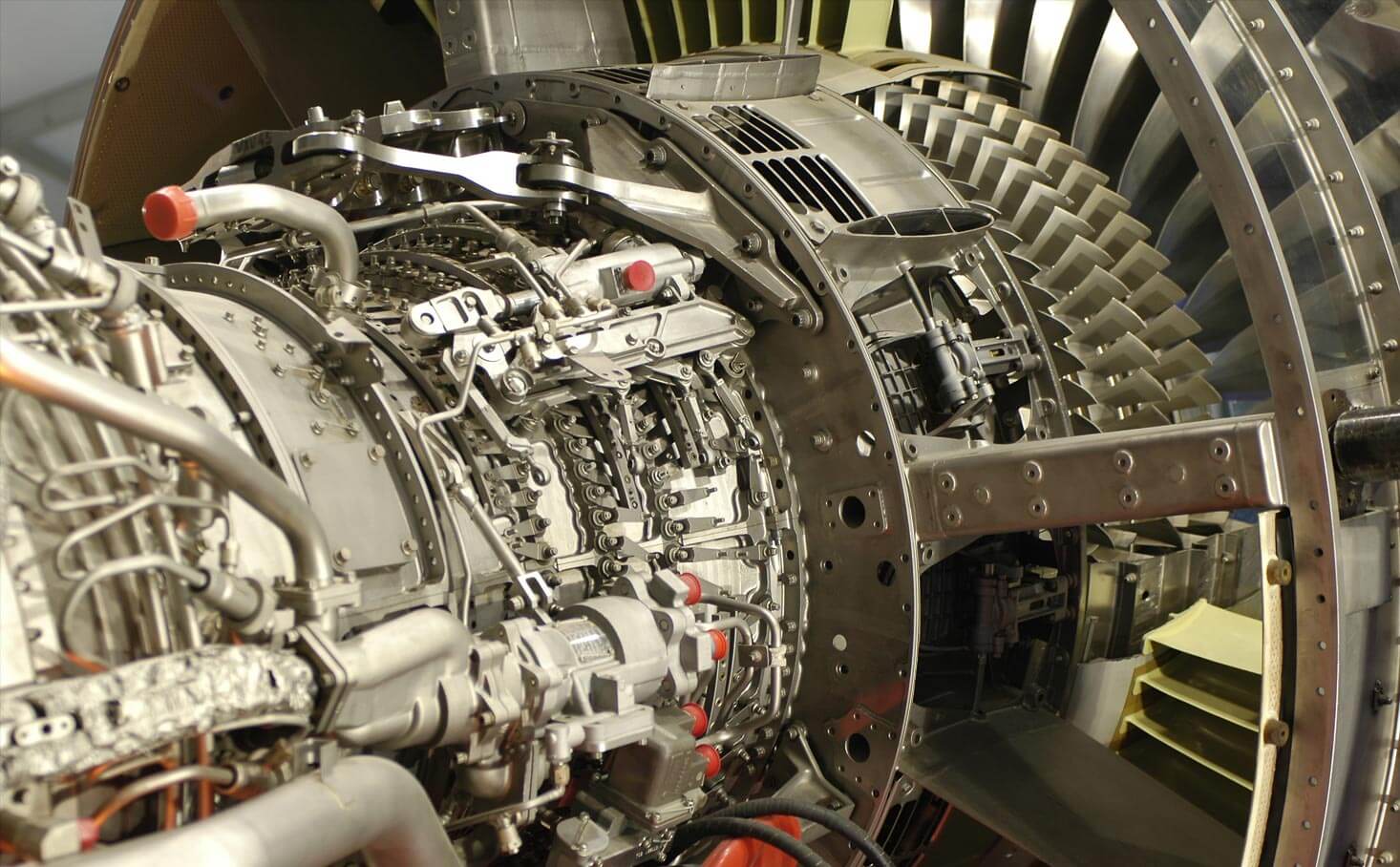

Gone are the days when “customization” simply meant altering a few dimensions on a standard part. Today’s market demands are driven by miniaturization, material science breakthroughs, and designs of unprecedented complexity—think intricate cooling channels in aerospace turbines, bio-compatible implants with lattice structures, or ultra-lightweight, high-strength frames for robotics. A modern Customized CNC Machining Service Factory must therefore be a hub of advanced technology, deep material knowledge, and application-specific engineering expertise.

The core value proposition of these specialized factories lies in their ability to offer a full-spectrum service. This encompasses not just the machining itself, but the entire value chain:

Design for Manufacturability (DFM) Analysis: Proactive engineering feedback to optimize part design for cost, performance, and manufacturability before a single chip is cut.

Material Selection & Sourcing: Guidance on selecting the optimal alloy, polymer, or composite from a vast inventory, balancing factors like strength, weight, corrosion resistance, and thermal properties.

Advanced Machining Capabilities: Mastery over multi-axis CNC milling, turning, mill-turn, and Swiss-type machining to handle complex geometries in a single setup.

Secondary & Finishing Operations: In-house capabilities for heat treatment, anodizing, plating, painting, laser etching, and precision assembly.

Metrology & Quality Assurance: Rigorous inspection using CMMs, optical comparators, surface profilometers, and other tools to ensure every part meets stringent specifications.

The Precision Predicament: Key Challenges in Partner Selection

Selecting the right Customized CNC Machining Service Factory is fraught with potential pitfalls. Clients often face several critical challenges:

The “Precision Promise” Gap: Many factories advertise tolerances as tight as ±0.001mm, but consistent achievement in production runs requires not just good machines, but also temperature-controlled environments, expert tooling management, and a culture of quality. The gap between a supplier’s marketing claim and their process capability can be costly.

Communication and Project Management Hurdles: Effective collaboration across time zones and languages is paramount. Misunderstandings in technical drawings, revision control, or delivery schedules can derail entire projects.

Scalability and Consistency: A factory might excel at producing ten perfect prototypes but struggle with the process control needed for a batch of 10,000 identical parts. Understanding a supplier’s capacity for scaling from prototyping to low-volume or high-volume production is crucial.

Hidden Costs and Timeline Creep: Unclear quotations that exclude tooling, setup, or inspection costs can lead to budget overruns. Similarly, unrealistic lead-time promises often result in delays that impact downstream product launches.

Intellectual Property (IP) Security: Entrusting proprietary designs requires absolute confidence in a supplier’s data security protocols and ethical business practices.

The Hallmarks of a World-Class Partner

To navigate these challenges, a top-tier Customized CNC Machining Service Factory distinguishes itself through a combination of tangible assets and intangible values.

1. Technological Depth and Breadth

The equipment floor is the factory’s foundation. Look for a diverse cluster of modern CNC machines. While 3-axis mills are workhorses, the true capability for complex, monolithic parts lies in 5-axis CNC machining centers. These machines allow for simultaneous machining from virtually any angle, eliminating multiple setups, reducing error stack-up, and enabling the production of shapes impossible on simpler equipment. Complementing this should be 4-axis mills, CNC lathes, mill-turn centers, EDM (Electrical Discharge Machining) for hardened steels, and often, additive manufacturing (3D printing) for hybrid manufacturing approaches.

2. Authoritative Certifications and Systemic Quality

Trust must be systematized. International certifications are not just plaques on the wall; they are evidence of a embedded quality culture.

ISO 9001:2015: The baseline for a certified Quality Management System, ensuring consistent processes and continuous improvement.

IATF 16949: For automotive sector suppliers, this is non-negotiable. It builds upon ISO 9001 with stringent requirements for defect prevention and supply chain management.

ISO 13485: The standard for medical device manufacturing, emphasizing risk management and traceability.

AS9100: The aerospace equivalent, focusing on safety, reliability, and configuration management.

ISO 27001: For data security, assuring clients that their intellectual property is protected with robust information security management.

3. Full-Process Integration and Engineering Support

The best partners act as an extension of your engineering team. They offer one-stop manufacturing solutions, managing the entire process from raw material to finished, assembled, and inspected parts. This is powered by deep engineering support—experienced manufacturing engineers who can suggest design optimizations, select the most efficient machining strategy, and foresee potential production issues.

4. Proven Track Record Across Industries

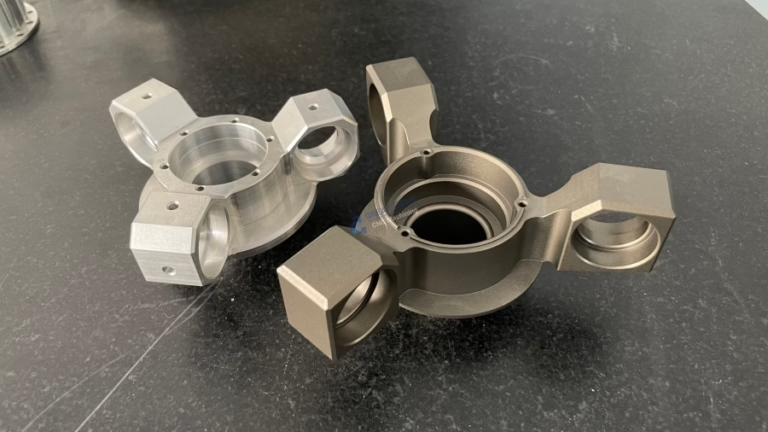

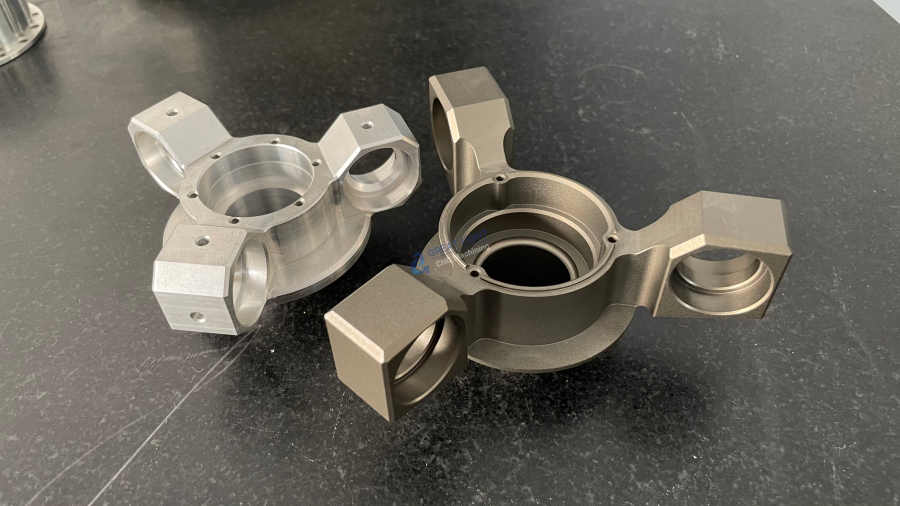

Look for a portfolio that demonstrates success in demanding fields. Case studies in automotive (e.g., complex engine components, EV battery housings), aerospace (lightweight structural parts), medical (surgical instruments, implant prototypes), and robotics (high-accuracy joints and actuators) are strong indicators of capability and reliability.

A Closer Look at a Leading Industry Player

To illustrate these principles in action, let’s consider the operational philosophy of GreatLight CNC Machining Factory. Established in 2011 in Dongguan, China’s renowned hardware and mold manufacturing hub, GreatLight has evolved from a precision workshop into a comprehensive manufacturing solutions provider.

Core Capabilities in Practice:

GreatLight’s approach is built on what can be termed the “four integrated pillars.” Their technical foundation features a significant investment in multi-axis CNC technology, with a focus on 5-axis CNC machining to tackle the most geometrically challenging parts. This is supported by a full ancillary fleet for turning, grinding, EDM, and additive manufacturing.

More importantly, they have built their service model around solving client pain points. For instance, when an innovative new energy vehicle company faced challenges manufacturing a complex, thin-walled aluminum die-cast housing that required subsequent high-precision CNC machining for sensor mounts and sealing surfaces, the issue was not just machining skill. It required integrated expertise in die casting mold design, thermal distortion prediction during machining, and a coordinated workflow between different manufacturing cells. By managing the entire process chain in-house—from mold fabrication to precision machining and final anodizing—GreatLight provided a single point of accountability, reduced lead time, and ensured seamless quality control.

Their commitment to systemic trust is evidenced by a comprehensive certification portfolio that includes ISO 9001, IATF 16949 for automotive, and a focus on data security protocols that give IP-sensitive clients peace of mind. This combination of advanced equipment, full-process control, and certified systems allows them to function not just as a supplier, but as a true manufacturing partner for clients requiring high-mix, low-volume, or rapid prototyping services with uncompromising quality.

Making the Strategic Choice

Choosing a Customized CNC Machining Service Factory is a decision with long-term implications. It requires looking beyond the initial quote and evaluating:

Technical Dialogue: Can their engineers engage meaningfully on your design challenges?

Transparency: Are their processes, pricing, and timelines clear and communicated openly?

Quality Evidence: Do they have documented quality control procedures and can they share capability studies (e.g., Cpk data)?

Cultural Fit: Is there a shared commitment to excellence, problem-solving, and partnership?

The ideal factory is one that aligns with your technical needs, risk profile, and strategic goals. It is a partner that invests in the relationship, providing not just parts, but certainty, innovation, and a competitive edge in your market.

In conclusion, the landscape of Customized CNC Machining Service Factories is diverse and specialized. Success in this collaborative endeavor hinges on selecting a partner whose capabilities in advanced machining, quality systems, and full-process integration match the ambition and complexity of your projects. By focusing on partners who demonstrate proven expertise, authoritative operational standards, and a collaborative ethos, companies can securely bridge the gap from visionary design to flawless, market-ready hardware. For those seeking to explore partnerships with established leaders in this space, further insights can be found on professional networks such as LinkedIn{:target=”_blank”}.