The world of custom housing parts CNC machining has grown exponentially over the years, with the advent of advanced technologies and manufacturing techniques. CNC machining, in particular, has changed the landscape of custom housing parts production, allowing for rapid prototyping, complex designs, and high-precision components.

At [Company Name], we pride ourselves on being a leading custom housing parts CNC machining supplier, offering a wide range of services including CNC milling, CNC turning, and 3D printing. Our team of experienced engineers and technicians work closely with clients to understand their unique needs and preferences, delivering high-quality, precision-engineered parts that meet the highest standards.

The Advantages of Custom Housing Parts CNC Machining

Custom housing parts CNC machining offers numerous advantages over traditional manufacturing methods. For one, it allows for the creation of complex geometries and intricate designs that would be impossible to produce using traditional methods. Additionally, CNC machining enables rapid prototyping, which significantly reduces the time-to-market for new products. This is particularly important in today’s fast-paced business environment, where speed and agility are key to success.

Another major benefit of custom housing parts CNC machining is its ability to produce high-precision components. By using computer-controlled machines, we can achieve tolerances of +/- 0.001mm, ensuring that our parts meet the highest standards of quality and accuracy. This level of precision is critical in industries such as aerospace, automotive, and medical devices, where even small variations can have significant consequences.

The CNC Machining Process

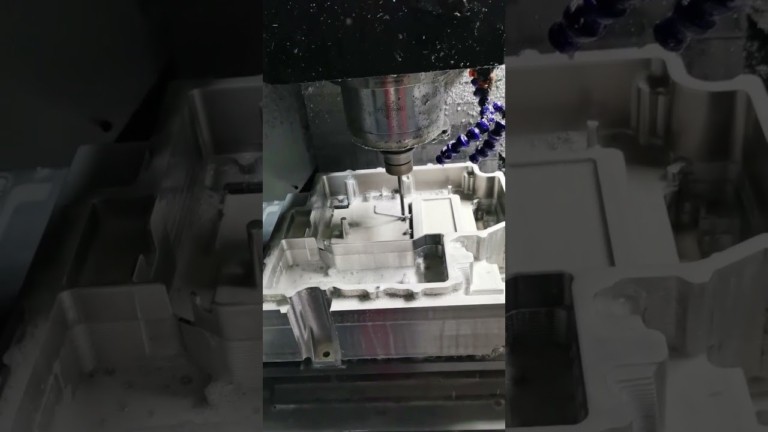

The CNC machining process involves using computer-controlled machines to remove material from a raw material, such as aluminum or steel, to create the desired shape and form. This process is highly precise and repeatable, allowing us to produce complex geometries and intricate designs with ease.

At [Company Name], we use a range of CNC machining techniques, including:

- CNC milling: This process involves using a rotating cutting tool to remove material from a workpiece. We can use a variety of cutting tools, such as end mills, face mills, and ball mills, to create complex geometries and contours.

- CNC turning: This process involves using a rotating cutting tool to remove material from the circumference of a workpiece. This technique is particularly useful for producing cylindrical parts, such as bearings and axles.

- 3D printing: This process involves using a layer-by-layer production technique to create complex geometries and structures. We use a range of 3D printing technologies, including Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Benefits of Working with a Custom Housing Parts CNC Machining Supplier

When you partner with [Company Name], you can expect the following benefits:

- Rapid Prototyping: Our CNC machining capabilities allow for rapid prototyping, which significantly reduces the time-to-market for new products.

- High-Precision Parts: Our machines are programmed to produce parts with tolerances of +/- 0.001mm, ensuring that your parts meet the highest standards of quality and accuracy.

- Complex Geometries: Our CNC machining capabilities allow us to produce complex geometries and intricate designs that would be impossible to produce using traditional manufacturing methods.

- Cost-Effective: By using CNC machining, we can produce parts at a lower cost than traditional manufacturing methods, which is particularly important for high-volume production runs.

- Expertise: Our team of experienced engineers and technicians work closely with you to understand your unique needs and preferences, providing expert guidance throughout the production process.

Industries We Serve

At [Company Name], we specialize in producing custom housing parts for a wide range of industries, including:

- Aerospace: We produce parts for aircraft and spacecraft, including bearings, axles, and other complex components.

- Automotive: We produce parts for the automotive industry, including engine components, transmission components, and suspension components.

- Medical Devices: We produce medical devices, including surgical instruments, implantable devices, and diagnostic equipment.

- Electronics: We produce components for the electronic industry, including circuit boards, modules, and other electronic components.

Conclusion

In conclusion, custom housing parts CNC machining is a rapidly evolving field that offers numerous advantages over traditional manufacturing methods. At [Company Name], we are committed to providing high-quality, precision-engineered parts that meet the highest standards of quality and accuracy. Whether you are looking to produce a single prototype or a large production run, we have the expertise and capabilities to meet your needs. Contact us today to learn more about our custom housing parts CNC machining services.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.