Custom 5-Axis CNC Parts: Unlocking Unparalleled Precision and Efficiency

In today’s fast-paced manufacturing landscape, companies are constantly seeking innovative solutions to stay ahead of the competition. One such solution is custom 5-axis CNC (Computer Numerical Controlled) machining, which offers unparalleled precision, efficiency, and flexibility. In this article, we’ll explore the benefits of custom 5-axis CNC parts and how they can revolutionize your manufacturing process.

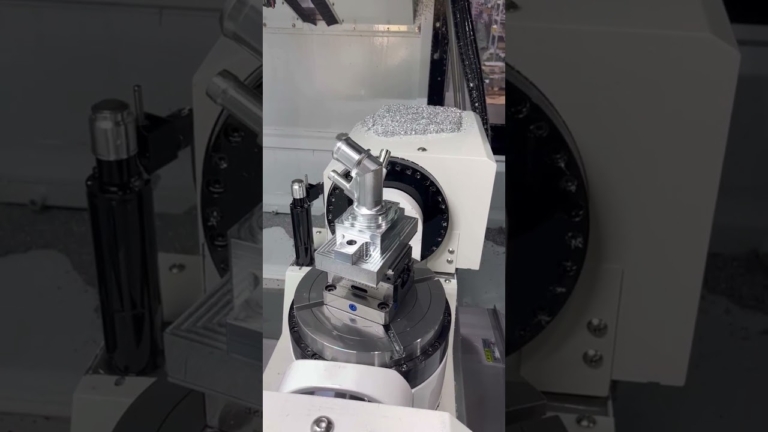

What is 5-Axis CNC Machining?

Conventional 3-axis CNC machining uses a three-axis control system, consisting of X, Y, and Z axes, to perform most machining operations. However, this approach has limitations, particularly when it comes to complex geometries, intricate designs, and dimensional tolerances. That’s where 5-axis CNC machining comes in. This advanced technology enables the control of an additional two axes – A and B – allowing for greater flexibility and precision.

Benefits of Custom 5-Axis CNC Parts

- Increased Precision: 5-axis CNC machining offers superior accuracy, even when working with complex shapes, irregular surfaces, and tight tolerances. This is particularly essential in industries where precision is critical, such as aerospace, medical, and automotive.

- Enhanced Portability: By reducing the number of tool changes and part handling, 5-axis CNC machining minimizes production time and increases overall efficiency. This leads to improved productivity and lower production costs.

- Wider Range of Applications: 5-axis CNC machining is ideal for complex component manufacturing, particularly in industries like defense, robotics, and energy. It’s perfect for producing parts with intricate geometries, such as turbine blades, aircraft components, or robotic arms.

- Reduced Material Waste: With 5-axis CNC machining, manufacturers can minimize material waste, as the machine can produce complex shapes and features in a single setup. This reduces material costs and reduces the environmental impact of production.

Custom 5-Axis CNC Parts: Real-World Applications

- Aerospace: 5-axis CNC machining is critical in the aerospace industry, where precision and lightweight components are essential for aircraft and spacecraft. Custom 5-axis CNC parts are used in engine components, structural components, and other critical components.

- Medical Devices: Medical devices, such as surgical instruments, implants, and prosthetics, require intricate designs and precision to ensure optimal performance and safety. 5-axis CNC machining is ideal for producing these complex components.

- Automotive: The automotive industry also benefits from custom 5-axis CNC parts, particularly in the production of high-performance engines, transmission components, and computer-controlled components.

How to Get Custom 5-Axis CNC Parts

To take advantage of the benefits of custom 5-axis CNC parts, consider the following steps:

- Choose a Reliable CNC Machining Partner: Select a partner with expertise in 5-axis CNC machining and a proven track record of producing high-quality parts.

- Discuss Your Requirements: Clearly communicate your project requirements, including material, specifications, and quantities.

- Collaborate on Design for Manufacturability (DFM): Work together to identify design elements that can be optimized for manufacturing, reducing costs and improving efficiency.

- Review Quality Control and Inspection Protocols: Ensure your partner has a robust quality control process in place, including regular inspections and testing to guarantee defect-free products.

Conclusion

Custom 5-axis CNC parts are revolutionizing manufacturing by offering unparalleled precision, efficiency, and flexibility. By choosing a reliable machining partner, discussing requirements, and collaborating on design for manufacturability, companies can unlock the full potential of 5-axis CNC machining. Whether you’re in the aerospace, medical, automotive, or other industries, custom 5-axis CNC parts can help you achieve unmatched quality and precision, giving you a competitive edge in today’s fast-paced global marketplace. Get a quote now and start unlocking the benefits of custom 5-axis CNC parts!

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.