Precision Meets Innovation: How GreatLight Metal Tech Redefines High-End CNC Machining

In the era of Industry 4.0, precision parts manufacturing has transcended traditional machining, evolving into a complex ecosystem where multi-axis CNC technology, material versatility, and integrated production chains determine success. For R&D teams, hardware startups, and industrial engineers, the challenge lies not just in achieving ±0.001mm tolerance but in finding a partner capable of translating bold designs into flawless reality—without compromising speed, cost, or quality.

This is where GreatLight Metal Tech Co., LTD. (operating as GreatLight CNC Machining Factory) stands apart. Since 2011, this Dongguan-based powerhouse has redefined precision manufacturing by combining five-axis CNC expertise, full-process chain integration, and ISO-certified quality systems to serve clients in robotics, aerospace, automotive, and medical sectors.

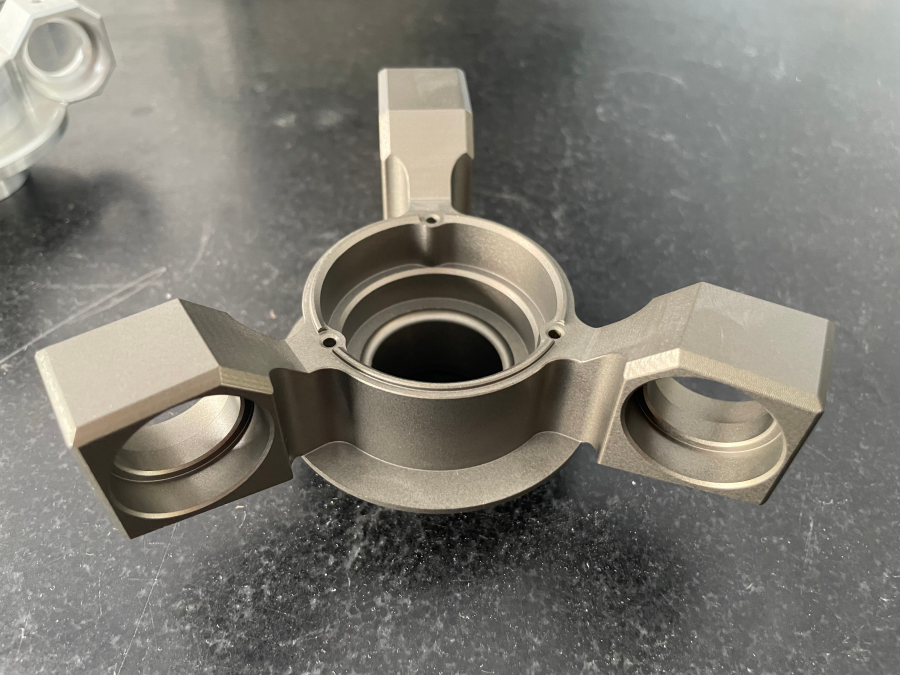

Why Five-Axis CNC Machining? The GreatLight Advantage

Traditional three-axis CNC machines excel at simple geometries but struggle with complex curves, undercuts, and multi-sided features. Four-axis systems add rotational capability, yet five-axis CNC machining remains the gold standard for:

Unmatched precision: Simultaneous tool movement across five axes reduces setup errors, achieving tolerances as tight as ±0.001mm.

Time efficiency: Single-clamping machining cuts lead times by up to 50% compared to multi-setup processes.

Material versatility: From titanium alloys to PEEK plastics, five-axis systems handle diverse materials with minimal distortion.

Cost optimization: Reduced labor and fixture costs make high-mix, low-volume production economically viable.

GreatLight Metal’s five-axis CNC machining services (learn more here) leverage Dema and Beijing Jingdiao high-speed centers, paired with in-house 3D printing and die casting for seamless prototyping-to-production transitions.

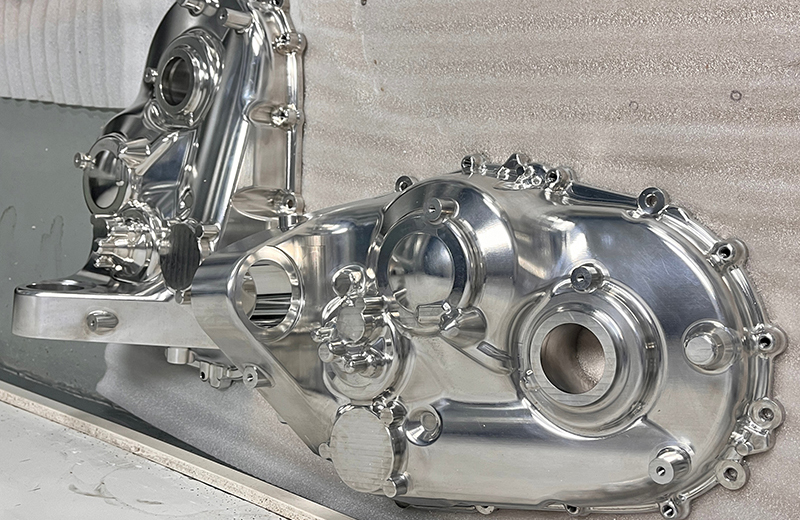

Beyond Machining: A Full-Process Chain for End-to-End Solutions

GreatLight Metal’s 7,600㎡ facility houses 127+ precision machines, including:

CNC milling/turning: For shafts, housings, and intricate components.

Die casting & vacuum forming: For lightweight, high-strength metal/plastic parts.

SLM/SLA/SLS 3D printing: Rapid prototyping in stainless steel, aluminum, titanium, and mold steel.

Post-processing: Anodizing, polishing, and laser etching for functional and aesthetic finishes.

This integrated ecosystem eliminates subcontractor risks, ensuring consistent quality from design to delivery. For example, a humanoid robot joint requiring titanium 3D printing + five-axis CNC finishing can be produced in-house, avoiding misalignment issues common in multi-vendor workflows.

Certifications That Matter: Building Trust Through Global Standards

In precision manufacturing, certifications are not checkboxes—they’re guarantees of reliability. GreatLight Metal’s accreditations include:

ISO 9001:2015: Foundational quality management for consistent output.

ISO 13485: Medical-grade compliance for surgical tools and implants.

IATF 16949: Automotive-specific QMS for engine components and safety-critical parts.

ISO 27001: Data security for IP-sensitive projects (e.g., aerospace designs).

These certifications, combined with 100% in-house inspection using CMM and laser scanning, ensure parts meet AS9100D (aerospace) and PPAP (automotive) requirements without exceptions.

Case Studies: Solving Real-World Challenges

1. Automotive: Conquering E-Motor Housing Complexity

A new energy vehicle (NEV) startup faced thermal distortion in aluminum e-motor housings. GreatLight Metal’s solution:

Five-axis CNC machining with cryogenic cooling to minimize heat stress.

Vacuum casting for near-net-shape prototypes, reducing material waste by 70%.

Final tolerance: ±0.005mm across 1.2m parts, enabling mass production in 8 weeks.

2. Aerospace: Lightweighting Satellite Components

For a low-Earth orbit satellite manufacturer, weight savings were critical. GreatLight Metal:

3D printed magnesium alloy brackets via SLM, achieving 40% weight reduction vs. machined aluminum.

Five-axis CNC finishing to ensure vibration-free mating surfaces.

100% X-ray inspection to verify porosity-free internal structures.

GreatLight Metal vs. Competitors: A Technical Comparison

| Factor | GreatLight Metal | Competitor A (Large-Scale) | Competitor B (Niche Shop) |

|---|---|---|---|

| Max Part Size | 4,000mm | 2,500mm | 1,500mm |

| Five-Axis Machines | 15+ (Dema/Jingdiao) | 8 (Mixed brands) | 2 (Entry-level) |

| 3D Printing Materials | Ti6Al4V, Inconel, PEEK | AlSi10Mg, Nylon | PLA, ABS |

| Certifications | ISO 9001, IATF 16949, ISO 13485 | ISO 9001 only | No formal certs |

| Lead Time (Prototypes) | 3–7 days | 10–14 days | 2–3 weeks |

Key Takeaway: GreatLight Metal balances scale (150 employees, 100M+ RMB annual sales) with agility, offering enterprise-grade quality at startup-friendly speeds.

Conclusion: Why GreatLight Metal Is the Future of Precision Manufacturing

In a world where 0.001mm can make or break a product, GreatLight Metal Tech Co., LTD. emerges as the ultimate partner for high-stakes projects. Its blend of five-axis CNC mastery, full-process integration, and global certifications ensures that even the most ambitious designs become reality—on time, on budget, and to specification.

Whether you’re developing robotic exoskeletons, aerospace actuators, or medical implants, GreatLight Metal’s 76,000 sq. ft. facility stands ready to transform your vision into precision-engineered parts.

Ready to experience the GreatLight difference? Explore our services or visit our LinkedIn profile for client testimonials.

Frequently Asked Questions (FAQs)

Q1: What industries does GreatLight Metal serve?

GreatLight Metal specializes in automotive, aerospace, medical, robotics, and industrial automation, with expertise in safety-critical components like engine parts, surgical tools, and humanoid robot joints.

Q2: How does GreatLight ensure data security for proprietary designs?

All projects comply with ISO 27001 standards, including NDAs, encrypted file transfers, and restricted facility access. Clients retain full IP ownership post-production.

Q3: Can GreatLight handle large-scale production runs?

Yes. With three wholly-owned plants and 127+ machines, GreatLight supports low-volume prototyping (1–100 pcs) and high-volume manufacturing (10,000+ pcs/month).

Q4: What materials does GreatLight work with?

The factory processes metals (aluminum, titanium, stainless steel, magnesium) and plastics (PEEK, Ultem, Nylon) via CNC machining, die casting, and 3D printing.

Q5: How does GreatLight’s pricing compare to competitors?

While not the cheapest, GreatLight offers transparent per-unit pricing with no hidden tooling fees. Volume discounts apply, and free rework/refunds guarantee quality.

Q6: What is the typical lead time for five-axis CNC parts?

Prototypes take 3–7 days; production runs require 2–4 weeks, depending on complexity and quantity. Rush orders are accommodated via dedicated shifts.

Q7: Does GreatLight provide design assistance?

Yes. The in-house engineering team offers DFM (Design for Manufacturing) feedback to optimize parts for cost and machinability before production begins.