Aluminum is the most widely used metal material among non-ferrous metals, and its application scope continues to expand. There are many types of aluminum products made from aluminum materials. According to statistics, there are more than 700,000 types of products, from the construction and decoration industry to the transportation industry and aerospace industry. Today I will introduce the processing technology of aluminum products and how to avoid deformation during processing.

The advantages and characteristics of aluminum are as follows:

1. Low density. The density of aluminum is approximately 2.7 g/cm3. Its density is only 1/3 that of iron or copper.

2. High plasticity. Aluminum has good ductility and can be processed into various products through pressure processing methods such as extrusion and stretching.

3. Corrosion resistance. Aluminum is a highly electronegative metal. Under natural conditions or during anodizing, a protective oxide film will form on the surface, which has much better corrosion resistance than steel.

4. Easy to reinforce. Pure aluminum is not very strong, but its strength can be increased by anodizing.

5. Easy surface treatment. Surface treatments can further improve or modify the surface properties of aluminum. The aluminum anodizing process is quite mature and stable and has been widely used in the processing of aluminum products.

6. Good conductivity and easy to recycle.

Aluminum product processing technology

Stamping of aluminum products

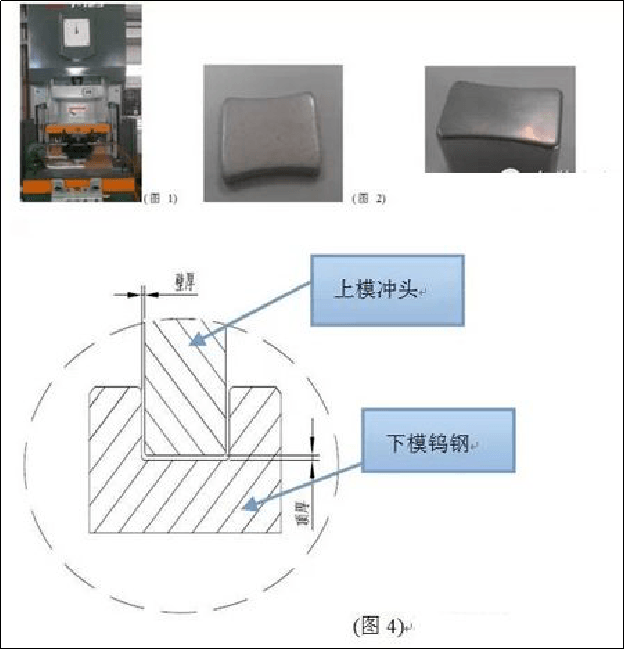

1. Cold Punch

The material used is aluminum pellets. The extrusion machine and mold are used for one-time molding, suitable for cylindrical products or product shapes that are difficult to obtain by stretching process, such as oval, square and rectangular products. (As shown in Figure 1 machine, Figure 2 aluminum particles, Figure 3 products)

The tonnage of the machine used is linked to the cross section of the product. The gap between the upper punch and the lower die tungsten steel is the wall thickness of the product. The vertical gap between the upper punch and. tungsten steel from the bottom die to the bottom dead center is the upper thickness of the product. (As shown in Figure 4)

Advantages: The mold opening cycle is shorter and the development cost is lower than that of the drawing mold.

Disadvantages: The production process is long, the product size fluctuates significantly during the process, and labor costs are high.

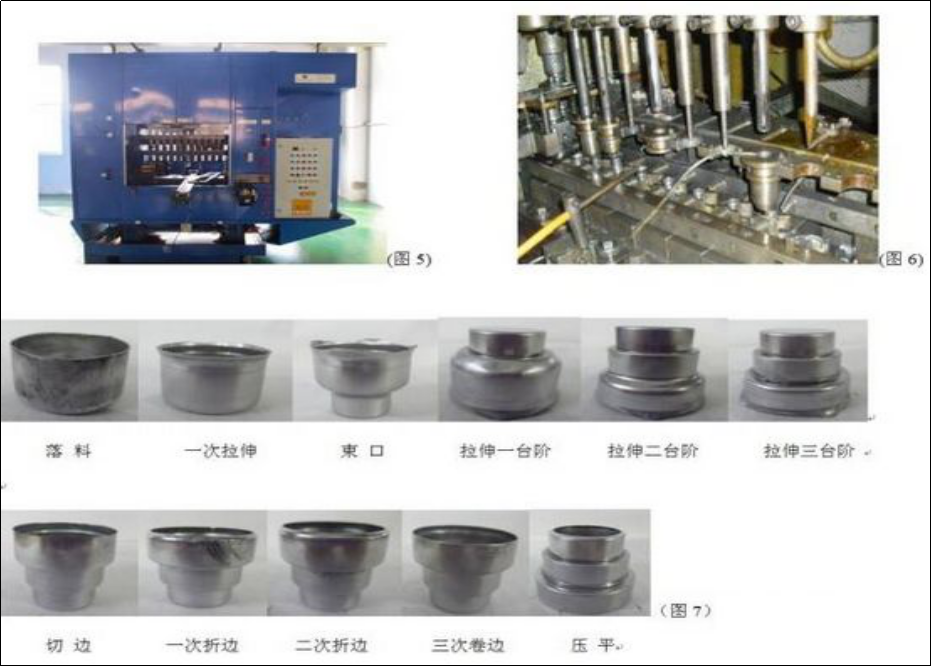

2. Stretching

Material used: aluminum skin. The continuous casting machine and mold are used to make multiple deformations to meet shape requirements, which is suitable for non-cylindrical bodies (produced with curved aluminum materials). (As shown in Figure 5 machine, Figure 6 mold, Figure 7 products)

Advantages: Products that are more complex and deformed several times have stable dimensional control during the production process, and the product surface is smoother.

Disadvantages: high mold cost, relatively long development cycle and high requirements for machine selection and precision.

Surface treatment of aluminum products

1. Sandblasting (shot blasting)

Process of cleaning and roughening metal surfaces using the impact of a high-velocity sand flow.

This surface treatment method of aluminum parts can achieve a certain degree of cleanliness and different roughness on the surface of the part, improving the mechanical properties of the surface of the part, thereby improving the fatigue resistance of the part and increasing the distance between it and the covering. Adhesion extends the durability of the coating film and is also beneficial for leveling and decorating the coating. This process is often seen in various Apple products.

2. Polishing

Processing method that uses mechanical, chemical or electrochemical effects to reduce the roughness of the part to obtain a shiny and smooth surface. The polishing process is mainly divided into: mechanical polishing, chemical polishing and electrolytic polishing. Aluminum parts are mechanically polished + electrolytically polished to achieve a stainless steel mirror effect. This process gives people a high-end, simple, fashionable and futuristic feeling.

3. Drawing

Metal drawing is a manufacturing process in which lines are repeatedly scratched onto aluminum sheets using sandpaper. Wire drawing can be divided into straight wire drawing, random wire drawing, spiral wire drawing and threaded wire drawing. The metal wire drawing process can clearly show every little trace, so that the matte metal shines with a luster of fine hair. The product is both trendy and technological.

4. High gloss cutting

A precision engraving machine is used to reinforce the diamond knife on the main shaft of the precision engraving machine which rotates at high speed (usually 20,000 rpm) to cut the workpieces, creating a local highlight area on the surface of the product. The brightness of the highlight is influenced by the rotation speed of the drill bit. The faster the drill speed, the clearer the highlight. On the contrary, the darker the highlight, the easier it is to produce tool marks. High-gloss cutting is especially used in mobile phones, such as iPhone 5. In recent years, some high-end TV metal frames have adopted high-gloss milling technology and anodizing and brushing processes. television as a whole. is full of fashion and cutting-edge technology.

5. Anodizing

Anodizing refers to the electrochemical oxidation of metals or alloys. Aluminum and its alloys form an oxide film on aluminum products (anode) under the action of an applied current in the corresponding electrolyte and under specific process conditions. Anodizing can not only solve the defects of aluminum surface hardness, wear resistance, etc., but also extend the service life of aluminum and improve its aesthetics. It has become an indispensable part of aluminum surface treatment and is currently the most widely used and successful. .Craftsmanship.

6. Two-color anode

Dual-color anodizing refers to anodizing a product and assigning different colors to specific areas. The two-color anodizing process is rarely used in the television industry because the process is complex and the cost is high. However, the contrast between the two colors can better reflect the high-end and unique appearance of the product.

Process Measures and Operating Techniques to Reduce Warping Related to Aluminum Processing

There are many reasons why aluminum parts deform during processing, which are related to the material, shape of the part, production conditions, etc. There are mainly the following aspects: deformation caused by internal stress of the blank, deformation caused by cutting force and cutting heat, and deformation caused by clamping force.

Process measures to reduce processing-related distortion

1. Reduce internal hair stress

The internal stresses of the blank can be partially eliminated by natural or artificial aging and vibration treatment. Pretreatment is also an effective treatment method. For blanks with big heads and big ears, due to the large margin, the deformation after processing is also large. If the excess part of the blank is processed in advance and the margin of each part is reduced, it can not only reduce the processing deformation in later processes, but also allow it to be left for a period of time after the pre-treatment, which can also release some of the internal stress.

2. Improve the cutting ability of the tool

The material and geometric parameters of the tool have a significant impact on the cutting force and cutting heat. The correct choice of tool is crucial to reduce the deformation of parts during processing.

1) Select the geometric parameters of the tool reasonably.

①Cutting angle: In order to maintain the strength of the blade, the cutting angle should be appropriately selected to be larger, on the one hand, it can grind a sharp edge, and on the other hand, it can reduce cutting deformation and smooth. chip removal, and thus reduces the cutting force and cutting temperature. Never use tools with negative cutting angles.

② Draft angle: The size of the draft angle has a direct impact on flank wear and the quality of the machined surface. The cutting thickness is an important condition for selecting the draft angle. When rough milling, due to the high feed rate, high cutting load and high heat generation, good heat dissipation conditions of the tool are required. Therefore, the draft angle should be selected to be smaller. When fine milling, the cutting edge should be sharp, reduce the friction between the flank surface and the machined surface, and reduce elastic deformation. Therefore, the draft angle must be larger.

③Helix angle: In order to make milling smooth and reduce milling force, the helix angle should be as large as possible.

④ Main deviation angle: Properly reducing the main deviation angle can improve the heat dissipation conditions and reduce the average temperature of the processing area.

2) Improve the structure of the tools.

① Reduce the number of teeth of the cutter and increase the chip space. Since the material of aluminum parts has greater plasticity, the cutting deformation during processing is greater and more chip space is required. Therefore, the lower radius of the chip groove should be larger and the number of teeth of the cutter should be smaller.

② Finely grind the teeth of the blade. The roughness value of the cutting edge of the tool teeth must be less than Ra=0.4 um. Before using a new knife, you should lightly grind the front and back of the teeth with a fine oil stone to remove burrs and slight jagged marks left when sharpening the teeth. In this way, not only the cutting heat can be reduced, but the cutting deformation is also smaller.

③Strictly control the wear standards of cutting tools. After tool wear, the surface roughness value of the workpiece increases, the cutting temperature increases, and the deformation of the workpiece increases. Therefore, in addition to selecting tool materials with good wear resistance, the tool wear standard should not be greater than 0.2mm, otherwise accumulated edge will easily occur. When cutting, the temperature of the part should generally not exceed 100°C to avoid deformation.

3. Improve the workpiece clamping method

For thin-walled, low-stiffness aluminum parts, the following tightening methods can be used to reduce distortion:

① For thin-walled ring parts, if a three-jaw self-centering chuck or spring-loaded chuck is used to clamp the parts in the radial direction, when loosened after processing, the workpiece will inevitably deform. At this point, a more rigid axial end face compression method should be used. Locate the inner hole of the part, make a homemade threaded chuck, insert it into the inner hole of the part, use a cover plate to press on the end face, then tighten it with a nut. Clamping deformation can be avoided when processing the outer circle, thereby achieving satisfactory processing accuracy.

② When processing thin-walled thin plate parts, it is better to use vacuum suction cups to achieve evenly distributed clamping force, and then use smaller cutting quantities to process, which can effectively prevent the part from becoming deformed.

Alternatively, packaging can be used. In order to increase the process rigidity of thin-walled parts, fluids can be filled inside the part to reduce the deformation of the part during clamping and cutting. For example, a urea melt containing 3-6% potassium nitrate is poured into the room. After processing, the filler can be dissolved and poured out by immersing the part in water or alcohol.

4. Organize the process reasonably

When cutting at high speed, due to the large machining allowance and intermittent cutting, the milling process often produces vibration, which affects the machining accuracy and surface roughness. Therefore, the high-speed CNC cutting process can generally be divided into: rough machining – semi-finishing – corner cleaning – finishing and other processes. For parts with high precision requirements, it is sometimes necessary to carry out secondary semi-finishing and then finishing. After rough machining, parts can be cooled naturally to eliminate internal stresses generated by rough machining and reduce deformation. The margin left after rough machining must be greater than the deformation, generally 1 to 2 mm. When finishing, the finished surface of the workpiece should maintain a uniform machining allowance, generally 0.2-0.5mm, so that the tool is in a stable state during processing, which can reduce greatly cutting deformation, achieve good surface treatment quality and guarantee product precision.

Operational skills to reduce processing distortion

Parts made of aluminum parts are deformed during processing. In addition to the above reasons, the operation method is also very important in actual operation.

1. For parts with large machining allowance, in order to have better heat dissipation conditions during processing and avoid heat concentration, symmetrical processing should be used during processing. For example, if there is a 90mm thick sheet that needs to be processed to 60mm, if one side is milled and the other side is milled immediately, and the final size is processed at one time, the flatness will reach 5mm if repeated symmetrically; processing is used, each side will be processed in two times. The final size can ensure that the flatness reaches 0.3mm.

2. If there are multiple cavities on the plate workpiece, it is not advisable to use the one-cavity and one-cavity sequential processing method during processing. This can easily cause uneven stress on the part and cause warping. Using layered processing multiple times, try to process all cavities at the same time in each layer, and then process the next layer to make the parts evenly stressed and reduce deformation.

3. Reduce the cutting force and cutting heat by changing the cutting amount. Among the three cutting quantity factors, the backcut quantity has a great influence on the cutting force. If the machining allowance is too large and the single-pass cutting force is too large, it will not only deform the workpiece, but also affect the rigidity of the machine tool spindle and reduce the durability of the tool . If the quantity of knife holder is reduced, production efficiency will be greatly reduced. However, CNC machining is all about high-speed milling, which can solve this problem. While reducing the amount of backcutting, as long as the feed is increased accordingly and the speed of the machine tool is increased, the cutting force can be reduced while ensuring processing efficiency.

4. Attention should also be paid to the cutting order. Rough machining focuses on improving processing efficiency and pursuing the removal rate per unit time. Generally, up milling can be used. That is, excess material on the surface of the blank is removed at the fastest speed and in the shortest possible time to essentially form the geometric outline required for finishing. The finishing process emphasizes high precision and high quality, so down milling should be used. Since the cutting thickness of the cutter teeth gradually decreases from the maximum to zero during milling, the degree of work hardening is significantly reduced, and the degree of workpiece deformation is also reduced.

5. Deformation of thin-walled parts due to clamping during processing is inevitable even if completed. In order to minimize the deformation of the workpiece, you can loosen the pressing part before finishing to reach the final size, so that the part can freely return to the original shape, and then lightly tighten it until the part can be tightened. (entirely according to the feeling), it can achieve the ideal treatment effect. In short, it is best to apply the clamping force to the supporting surface, and the clamping force should act in the direction of good rigidity of the part, assuming that the part does not loosen , the lower the clamping force. the better.

6. When processing workpieces with a cavity, try not to let the cutter penetrate directly into the workpiece like a drill when processing the cavity. This would result in insufficient chip space for the cutter and poor chip removal, leading to overheating and expansion. and room collapse. Unfavorable phenomena such as broken knives and knives. First use a drill bit the same size as the countersink or one size larger to drill the hole, then use the countersink to countersink it. Alternatively, CAM software can be used to produce a spiral cutting program.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.