1 preface

The machine-to-filming machine is an important branch of the machine tool family. Its structural characteristic is that it combines the advantages of towers and milling machines. It can not only turn high precision rotary bodies, but also carry out various milling operations. can only be supplemented by strawberries. The most common-made tool-tool with the most common shooting consists of installing a motor head on the Tour Turret to perform the milling task of rotary parts.[1,2]. The CNC Siemens system provides a method of ending end (transmit) and cylindrical face (tracyl) to convert the rotation of the spindle into virtual x and y axes, which makes programming for filming made up of filming -Freshing fundamentally the same as that of milling composed of filming-firing. Method of programming a milling machine, considerably reducing the programming difficulty.[3]。

2 main technical requirements and drawing technology

2.1 Main technical requirements for drawings of filming and milling parts

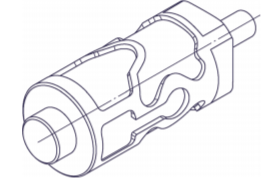

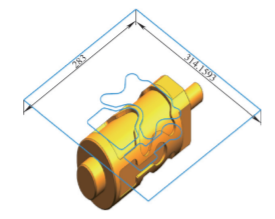

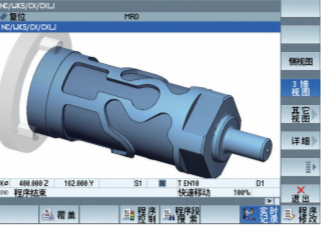

The three -dimensional model of filming and milling parts is illustrated in Figure 1. The material is an aluminum alloy hard LY15. The blank size is φ102 mm × 283 mm. The depth of the outline of the outer surface and the inner cavity is 5 mm. The curve of the inner cavity of the outline is it6. Personalization with three claws is used. The central chuck is tight with a higher tightening method.

Figure 1 3D model of filming and milling parts

2.2 Treatment technology

The three-claw self-cherry chuck is used to tighten an upper and top to finish the filming of the outer circle and the strawberry of the cavity of the outdoor circle outline. Filming the outer circle: Use a diamond -shaped brochure with an 80 ° blade angle and a point radius of R1.2 mm to treat the outside circle. The quantity of rear cut for coarse filming is 1.2 mm each time, leaving room. For the outer circle and the end face. Measure 0.3 mm for the finish. Treatment of the external strawberry contour cavity: use a strawberry at the end of φ8 mm (EN8) to quickly remove the material inside the cavity. The quantity of cut is 5 mm each time, leaving a margin of 0.3 mm on the side wall and the lower surface for the finish. Fracking the right end of the square table of the part: coarse milling with a strawberry at the end of φ10 mm (EN10), using the side edge of the strawberry at the end to quickly eliminate the room of the room, the quantity of AP rear cut is 30 mm, the maximum cutting width of the side wall is 0.8 mm, and the side wall and the lower surface are left. Leave a 0.3 mm margin for the finish.

3. Frack programming process for filming and milling parts

3.1 Import of patterns

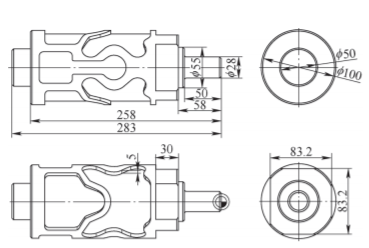

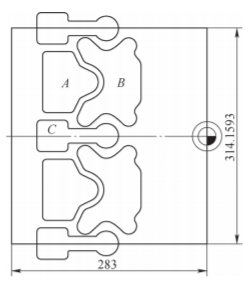

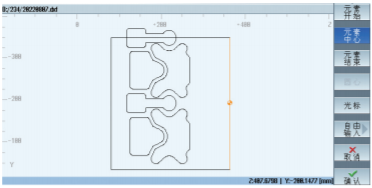

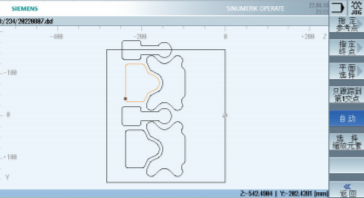

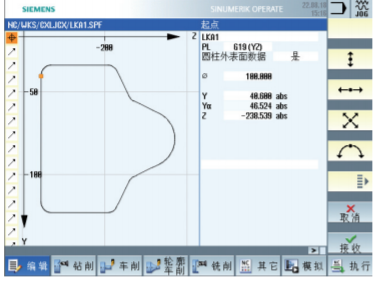

The part model is imported into the system. The two -dimensional model of filming and milling parts is illustrated in Figure 2 and must be converted into a two -dimensional CAD model. The outdoor circle shooting program uses the DXF Reader contour editor function provided with the CNC Siemens system. This function can carry out the rapid conversion of parts of parts into machining programs, as shown in Figure 3.

Figure 2 two -dimensional model of filming and milling parts

a) Generation interface of filming cycles

b) Contour generation interface

Figure 3 Function of the outline editor

3.2 Edition of the draft machining program for the cavity of the exterior surface of the cylinder

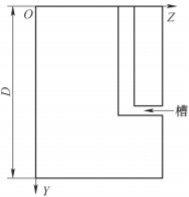

(1) Cylindrical conversion (Tracyl) provides a cylindrical conversion programming method in the CNC Siemens system. The control system converts the programmed power instructions for the Cartesian coordinate system into a real coordinating system. Thanks to the conversion of Cylinder Tracyl (D), the system will automatically gener a virtual Y axis and enlarged the cylinder in a plan for programming. Figure 4 shows the outer surface of the YZ programming plan (G19) formed by the rolling cylinder of outside diameter D. The direction of rotation is defined by G2 and G3. During programming, you just have to take into account the relationship between the X axis, the Y axis and the Z axis. It is not necessary to take into account the position relationship of the spindle C. When The system automatically converts and programming, the depth direction is X. Axis.

Figure 4 Example of cylinder conversion

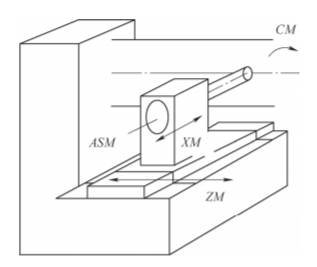

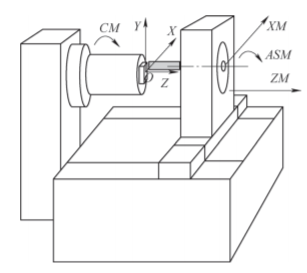

Figure 5 is an example of using XCZ movement to treat the exterior surface of a cylinder. In the axis of movement of a standard tower (without axis of coordinates Y), the two linear axes XM and ZM are perpendicular to each other, as well as the rotation axis. CM is parallel to the ZM linear axis (revolving around the ZM linear axis), the XM linear axis cuts the rotation axis CM (rotation center).

Figure 5 Example of machining on the outer surface of a cylinder using the XCZ movement

The tracyl function can be activated by programming in a separate block via tracyl (D), where D is the diameter of the cylinder machining (mm) It can be deactivated by programming in a block separate by Trafoof, which will cancel any valid conversion ; function. Depending on the programmed YZ trajectory (straight line or trajectory), the coordinate axes of the ZM and CM machine-tool are moved so that the treatment of the outline can be carried out by the strawberry on the exterior surface of the cylinder, and the ‘programmed X axis is always used. as ahead of the X axis.

The writing steps of a coarse machining program for the exterior surface of a cylinder are as follows.

1) Write the instructions for preparing the milling process in order on the program editing page, as detailed below. N14G54G19G95G40; Initializing the milling environment

N15T = “EN8” D1; Strawberry at the end φ8 mm

N16setms (3); Pin (3) as main spindle

N17 M3 = 3 S3 = 2000; 2000 rpm electric knife speed.

N18 Tracyl (100); Activate cylindrical conversion, the reference diameter is 100 mm.

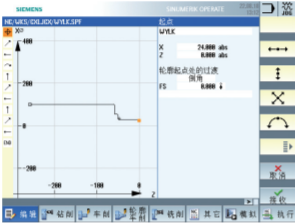

2) Develop the outline of the exterior surface of the cylinder in UGNX software, as indicated in Figure 6.

a) three -dimensional structure

b) two -dimensional expansion

Figure 6 Expansion of the outdoor circle of the filming and milling parts

3) Write a program for coarse machining of the cavity of the exterior circular outline. As there are many program segments, only outline A is used here as an example. Press “Others” on the program editing page, select “sub-program” and call “LKA1.SPF” as sub-program, the following program instructions can be generated.

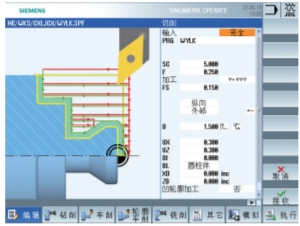

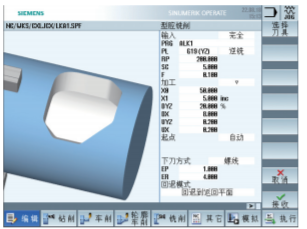

N22Call “LKA1.SPF” To edit the outline sub-program, you must first create a sub-program with the file name “LKA1.SPF” in the main program of the program, select “Contour Milling” on the page of the program edition to access its page, and press the programmable key on the right “Contour call”, enter the name of the “LKA1” profile, press “Accept” to confirm the outline call, enter the settings Processes indicated in Figure 7, interface for entering the milling cycle under “outline strawberry” → “cavity”. “, Press” Accept “to confirm the parameters of the cavity’s milling process, enter the M17 control after cycle63 and the sub-program ends. The procedure is as follows.

Figure 7 Input interface of the milling cycle

N2cycle62 (“LKA1”, 1 ,,)

N3cycle63 (“Alk1”, 11,200,50,5.0.0.1,0.20,8,0.0.0.2,1,0,4,1,15,2, “”, 1 ,, 0.103.111)

N4M17

Second, you must create the A contour A in the CNC system, use the DXF Reader contour publisher function provided with the CNC Siemens system and copy the file with the DXF suffix generated by CAD in the system. On the program editing page, click on “Contour strawberry” → “outline” → “new outline”, click “Import from DXF” on the right to enter the LKA1 profile name, select the circle outline file Exterior to copy to the system, and select the specified reference point as “” element center “, select the straight line on the right side of the outline and the origin of the part programming is set to coincide with the ‘Origin of filming programming. To accept the outline of the cavity.

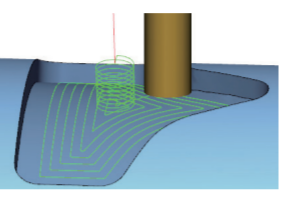

Figure 8 The generated tool path

a) Select the origin of the programming

b) Generate closed contours

c) Accept the outline of the cavity

Figure 9 stages of generation of the cavity outline

(2) Conversion of end faces (transmitted) The conversion function of end faces is often used when processing composites in filming and milling. After converting the final face, the system will automatically generate a virtual y axis. For example, when milling a square on the end, you just have to program the positions of the X and Y axes, and the system will convert them automatically, considerably simplifying the programming difficulty. The control system converts the programmed power instructions from the Cartesian coordinate system to the real coordinate system. The extremity face facing function is activated by transmit in a separate block and deactivated by Trafoof, which will cancel any active transformation function.

By taking the piece in Figure 10 as an example, Transmit is used to make the strawberry of the end faces on filming and milling parts. In the figure, X, Y and Z are the Cartesian coordinate systems for programming the treatment of end faces, and ASM is the second. Pin (used for strawberries and forests), ZM is the Z coordinate axis of the tool machine (linear axis), XM is the X coordinate axis of the (linear) machine, CM is the Coordinate axis C (The main pin is used as a rotation axis).

Figure 10 Example of frontal milling of filming and milling parts with transmit

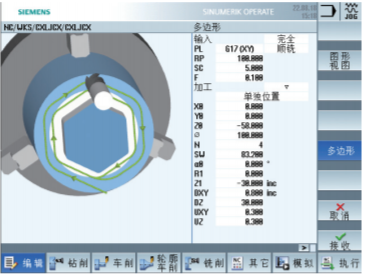

To write a coarse machining program for a square milling table, the Siemens system provides many fixed cycle instructions and the program can be modified with only a few simple parameters. The square boss of this part uses the polygonal boss milling programming instruction cycle79. Enter the settings of the milling process in Figure 11 in the interface to enter parameters of the polygonal boss milling cycle to generate the required program for legend.

N36Cycle79 (100, -58.5, -30,4,83.2,0,0,0,0,100.0.8,30,0.3.0.0.0.0.0,1,2,100,101)

Figure 11 Input interface of the parameters of the Fracking Cycle of the polygonal boss

(3) Write the end -of -program instructions program as follows.

N37 Trans; Cancel the conversion

N38 G0 X200 Z200 M5 M9

N39M30

It should be emphasized that the Trafoof cancellation conversion control must be specified once after the transmitted end surface conversion and the conversion of tracyl cylinder are finished, otherwise the CNC system will trigger an alarm. The finishing program must only be modified accordingly in cycles Cycle63 and cycle79. Due to space constraints, we will not present them here. The main set of parts filming program is as follows, and the simulation of the treatment of filming and milling parts is illustrated in Figure 12.

Part N1 (,,, “cylinder”, 0.0,- 283, -270,102); Define the diameter of the blank as being 102 mm, length 283 mm, tightening – 270 mm;

N3 G90 G54 G18 G95 G40; Initializing the shooting environment

N4 Diamon; Activate the diameter programming command.

N5 LIMS = 2000; Speed limit of the main spindle 2000 rpm N6 G0 x200 Z100 m8

N7 M4 G96 S100

N8 t = ”redlying_t80 a” d1; The angle of the blade is a 80 ° cylindrical shooting tool.

N9 Call “Wylk.spf”; Call of the outline sub-program of the exterior circle rotating

N10 G0 x200

N11Z200M5

N12M9

N13M0

MSG (“Milling Contour Program”);

N14 G54 G19 G95 G40; Initialize the milling processing environment.

N15 T = “EN8” D1; Strawberry at the end φ8 mm

N16 Setms (3); Pin (3) as main spindle

N17 M3 = 3 S3 = 2000; 2000 rpm electric knife speed.

N18 Tracyl (100); Activate cylindrical conversion, treat MSG 100 mm in diameter (“Milling Contour B”)

N19cycle62 (“LKB1”, 0 ,,); Contour B

N20Cycle63 (“B1LK”, 11,200.50.5,0.0.1,0.40,8,0.0.0.0,0,4,1,15,2, “”, 1 ,, 0.103.111 );

N21cycle62 (“lkb2”, 0 ,,)

N22Cycle63 (“B2LK”, 11,200,50,5.0.0.0.0.40,8,0.2,0.0,0,0,4,15,1,2, “”, 1,, 0.103.11)

MSG (“Fresh Profile A”)

N23 Call “LKA1.SPF”; Call the sub-program for the Four Contour A.

N24 Call “LKA2.SPF”

MSG (“Milling Contour C”) N25 CALL “LKC1.SPF” N26 CALL “LKC2.SPF” N27 TRAFOOF; Cancels all active transformations;

N28m0m5

N29M9

MSG (“Milling End Square”)

N31 Setms; Setms does not contain a spindle specification, go back to the main pin defined by the system.

N32 G0 X200 Z200

N33 T = ”EN10” D1; Strawberry at the end φ10 mm

N34 Settings (3)

N35 m3 = 3 S3 = 2000

N36 G0 X0 Z50

N37 transmit; Activate the transformation of the final face

N38CYCLE79 (100, -58.5, -30,4,83.2,0,0,0,100,0.8,30,0.3.0.0.0.0,1,2,100,101);

N39 TRAFAOF

N40 G0 X200 Z200 M5

N41M9

N42M30

Figure 12 Simulation of filming and milling parts

4 Conclusion

When you use end -to -face (transmit) and cylindrical front conversion (Tracyl) conversion (Tracyl) conversion commands, you must write the appropriate instructions in the treatment program to declare to the system that you must currently go to Frack. The commonly used instructions include Setms (2): programming of the head of the electric tool as a spindle; Transmitted: Beginning of the conversion of the end face; Tracyl (D): Beginning of the conversion of the cylindrical side, where D is the diameter of the cylindrical part Trafoof: end; conversion; M2 = 3 S2 = 1000: The speed of the electric tool is 1000 rpm; MCALL: Cancel the modal call (Z1, C): the C axis and the Z axis make a linked interpolation;

Sinumerik Operate DXF-Reader is supplied by the CNC Siemens system. It is a very practical and practical contours reading and editing tool. It is used in conjunction with the contours publisher and the Sinumerik Operate process cycle. 2D FAO software “without post-treatment”. From programming of the above parts, we can see that the processing of the whole part can be carried out using this method of outline treatment. Since the DXF editor is used on the system, the part drawing is directly converted into a real treatment program. Thus the editing of the outline is greatly simplified and extremely dadi facilitates the programming work of the operator and improves the efficiency of the programming. The use of the integrated SIEMENS machining cycle can considerably reduce the duration of the program and reduce the on -site programming workload. However, you have to pay attention to the sign of value when entering value in man-machine dialogue. interface.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.