2022Year11moon23Japan, Siemens and machine tool manufacturersDMG MORI UNITED STATEStool makerWalterAndTRAK machine toolscollaboration, demonstrating the power of digitalization in design and engineering workflows.

△SiemenseRod Conceptual electric car. (Image source: Siemens)

This collaboration is based on SiemensXceleratorBusiness platform, showing the potential of optimization as a fundamental component of manufacturing design and engineering, for SiemenseRodWhen designing and manufacturing steering knuckles for electric vehicles, new and traditional technologies are combined to reduce waste and maximize resource utilization.

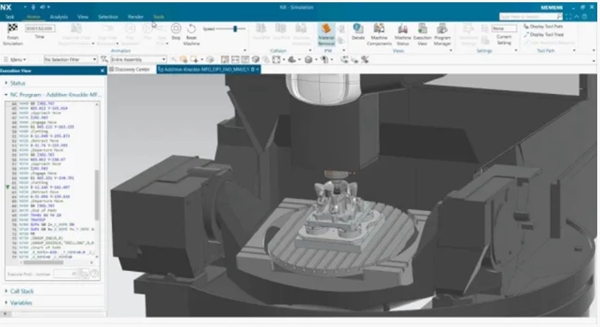

△G-code NXCAMled3DSimulation of a printed steering knuckle (Image source: Siemens)

The digital processes demonstrated in this collaboration integrate technologies from all four companies, starting with Siemens.NXGenerate the initial design. In this case, the partners used integrated generative engineering tools such as design space exploration to use the operating parameters of the electric vehicle to optimize the design of the parts.

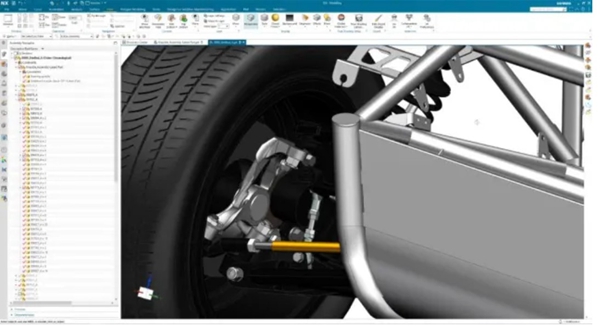

△Installed ineRodSimulation of a topology-optimized steering knuckle assembly (Image source: Siemens)

During the design phase of additive manufacturing, parts are validated using structural simulation and optimization to ensure performance requirements are met and optimized for production-ready manufacturing processes . In this project, the simulation-based design ensured that the part was created with minimal materials, making the steering knuckle design easier.45%weight and improves the resilience of the part to the stresses it generally undergoes.

During this planning stage of the process, partners useTeam CenterAndOpcenterThe software develops complete manufacturing plans. This helps manufacturers automate programming by applying their own standard CNC programming, inspection path methods, tools and program templates. It also ensures that the correct revisions are scheduled and measured on the shop floor, creating a single source of data for the entire digital manufacturing process.

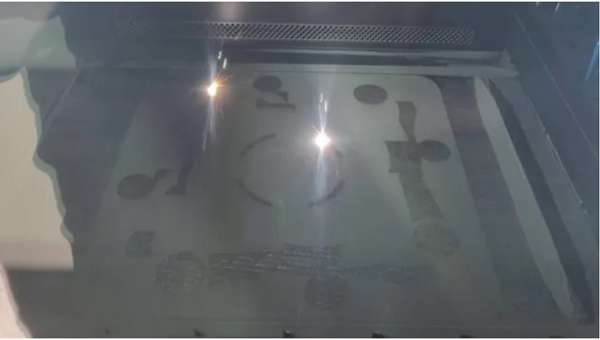

△InDMGMORI LASERTEC 30 DOUBLE SLMsuperior3DPrinted steering knuckle (Image source: Siemens)

During the manufacturing phase, parts are manufactured using a combination of additive manufacturing and traditional manufacturing methods and then machined to achieve dimensional accuracy and tolerances. Siemens claims that programming time is reduced by using software to automate routine tasks at this stage.60%. This part is inCAM NXIt is prepared and programmed for additive manufacturing and traditional subtractive manufacturing using five-axis simultaneous programming, cloud-based post-processing and integrated simulation. then inDMG MORI LASERTEC 30 DOUBLESelective laser fusion (GDT) for use on boardTi6Al4VTitanium powder is produced. Final tolerances and surface treatments are determined byDMG MORIofDMU 85 monoBLOCKProduced on a five-axis machining center equipped withSINUMERIK840D slCNC system for two-step processing. The machine is also equipped withWalterTools designed for finishing and cutting operations.

△InDMGMORI monoBLOC 85Superior processing3DPrinted steering knuckle (Image source: Siemens)

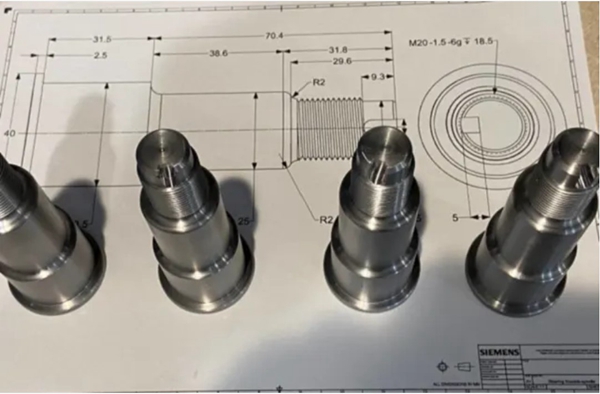

In addition to the challenges often encountered during processing, the additive manufacturing process for titanium alloys also presents many other challenges. While additive manufacturing excels in the production of complex parts, the machining of these parts is rarely simple.3DThe support structures needed for printing tend to be more fragile than bulk materials, and3DPrinted structures often present characteristics that are difficult to achieve with standard tools. These parts with complex geometries are often difficult to clamp during machining, meaning that minimizing vibration is essential to reducing the risk of part damage. To meet these challenges,WalterA process using combined tooling has been developed to provide finished parts meeting all dimensional accuracy and surface finish requirements. When evaluating the entire assembly, the design team discovered that some components could still be manufactured more efficiently using traditional processes. The spindle is specifically suitable for CNC turning. To make this change, engineers usedRun MyVirtual Mach(digital twin system) TRAK MachineTools TC820si Turning centers add to the digital manufacturing process. The pin is inSINUMERIK ONEpassed into controllerShop tourProgram virtually with conversational programming, then useTC820siof3DCheck on both machines.

△The wheel joint spindle is very suitable for traditional turning operations (Image source: Siemens)

To close the loop, quality control and production preparation are carried out usingMMT NXDetection in programming softwarePMI index(product manufacturing information) collection and storage of automatically driven dimensional and tolerance dataMMTProcess carried out to ensure parts are within expected tolerances and ready for assembly. During the final assembly process, the more traditional spindle components are connected to the newly optimized joints and installed on the Siemens.eRodsuperior.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.