Mastering the Rotation: An In-depth Guide to CNC Steering Technology

In the world of precision manufacturing, CNC turns are the basic pillar. This is the process of changing cylindrical workpieces, creating an essential part of countless industries – from complex aerospace components to robust automotive axles and exquisite medical devices. In Greatlight CNC machining, we use all advanced turning techniques every day to push possible boundaries, especially our exquisite five-axis functionality. This guide delves into key CNC turning methods and reveals the expertise required to achieve excellent results.

Learn about the core: How CNC rotation works

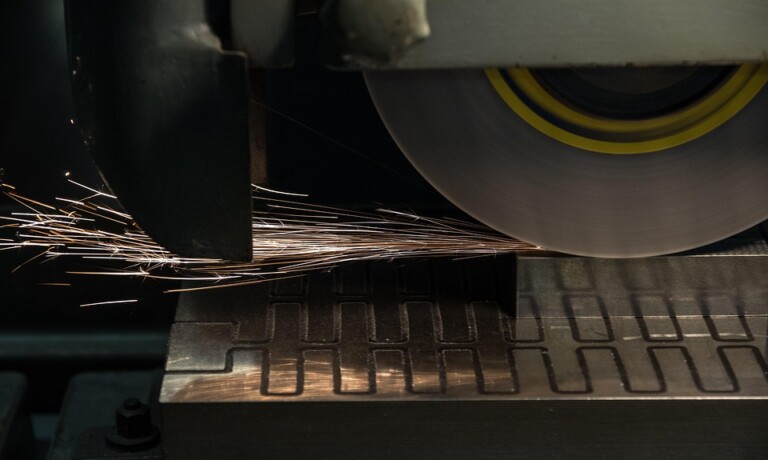

Before exploring specific technologies, let’s build on the basics. During CNC rotation, the workpiece is securely mounted on the spindle and rotates at high speed. A non-rotational cutting tool precisely controlled by a computer description (G code) is fed onto the rotating material to remove excess metal. This basic interaction produces cylinders, cones, contours and even complex geometries (especially using multi-axis machines). The core of the CNC lathe includes a spindle, tool turret, tail holder (for support), guide and complex CNC control units.

Essential CNC Turning Techniques: Beyond the Basics

Mastering the techniques that turn involves choosing and performing the right techniques for the job. Here is a detailed introduction to the core approach and its strategic applications:

- face: This is usually the first operation. The single point tool moves radially over the entire face (end) of the rotating workpiece to form a perfectly flat surface perpendicular to the axis of rotation. Ideal for determining precise part length and clean final features. (Greatlight Insight: Precision Faceing is essential to ensure follow-up operations starting with a real, reliable benchmark.)

- Straight (cylindrical) turn/OD turn: The main force in the turn. The cutting tool moves parallel to the workpiece axis, reducing its diameter to a specific size and creating a smooth cylindrical surface. This can be rough (actively removing bulk material) or finished (realizing the final size and finish). (Greatlight Insight: The best cutting parameters (speed, feed, cutting depth) selected by our engineers ensure roughness and perfect finishing efficiency when needed.)

- Taper rotation: Create a conical surface with a diameter gradually changing along the length of the workpiece. Implemented by precise cancellation tools or tail retention, or by interpolation motion programmed on CNC lathes. (Greatlight Insight: Five-axis machines perform well with complex taper and blank shapes without mechanical adjustments, saving a lot of setup time.)

- analyze: Cutting tools follow a specific programmed path, often involving multiple axes of motion to create complex non-cylindrical contours on either outer diameter (OD) or inner diameter (ID) (ID). Think of a camshaft or a turbine rotor. (Greatlight Advantage: Our 5-axis CNC turn center shines here, creating complex organic profiles with unparalleled accuracy and surface quality in a single setup.)

- Slot (OD slot/ID slot): Use a tool of special shape to cut narrow channels (grooves) of a part of an OD, ID or a specific width and depth on the face. For sealing, fixing rings, separate components or purely aesthetic features. (Greatlight Tip: Accurate slots require rigid settings and optimized tool geometry to prevent tremors and ensure dimensional accuracy, especially in deep or narrow grooves.

- Separate/Cut off: A specific type of slot operation in which blade-like tools cut into the workpiece completely to separate the finished part from the parent stock.

- Boring: Internal machining operations are used to expand existing holes or cavity generated by drilling, casting or forging. A single point drilling reaches the inside of the workpiece for precise ID dimensions, high-quality finishes, straightness and concentricity – often beyond what a separate drill bit can achieve. (Greatlight expertise: Deep hole requirements require specialized tool strategies (e.g., static or dynamic damping rods) to offset vibration and tool deflection to ensure critical hole tolerances such as cylinders.)

- Drilling with Rennes: They are often performed on CNC lathes while mainly drilling operations. Drills mounted on the turret create an initial hole axially. Rotate then lifts the hole to very precise size and finish. (Greatlight Exercise: Combining drilling with subsequent drilling and/or drilling on the same computer ensures excellent hole concentricity and positional accuracy relative to cornering.

- Thread (internal/external): Cut precise helices with a dedicated thread tool (for custom threading) or thread factory/thread mold. CNC slats rotate accurately synchronize tool movement to create accurate line form. (Greglight Features: We process everything from standard metrics/imperial threads to complex multi-starts and custom aerospace.)

- effort: Form an operation (substituting metal to a large extent rather than cutting) creates textured diamonds or straight patterns on the part’s OD to improve grip strength. The knurled tool presses into the rotating workpiece under high pressure.

- Form transfer: Use a cutting tool to specifically ground the profile to the desired final shape to shape the workpiece. The entire table is cut in a single drop motion (radial feeding), although usually required to be completed. Effectively used in simple, repeating shapes.

Achieve precision and quality: Key considerations

- Material selection and processability: It is crucial to understand the performance of different metals (e.g., aluminum, stainless steel, titanium, stainless steel, stainless steel, inconel, copper tube) during the cutting process. This can affect tool selection, speed, feed, coolant and overall strategy.

- Tool selection and geometry: Carbide inserts are dominated by various grades, coatings (TIN, TICN, Al₂o₃) and geometry (rake angle, nose radius) and can be optimized for specific materials, operation (rough, finish) and required chip control.

- Cut parameters (v, c, f, doc): Optimizing spindle speed (surface speed – V, C), feed rate (F), and cutting depth (DOC) is a science. Balance these balances can maximize material removal without sacrificing tool life or part quality.

- labor force: Secure clamping between centers or between professional fixtures using Chuck (3 jaw, collet) is critical to accuracy, preventing vibrations (chat), and ensuring that the jump is minimized. (Greatlight Precision: Our focus on labor solutions minimizes part deformation and maximizes position accuracy.)

- Coolant Strategy: Flood coolant, high pressure coolant (HPC), minimum lubrication (MQL) or compressed air all hit the chip evacuation, tool cooling, surface finish and dimensional stability, is especially important in high-speed turning or viscous materials.

- Tool path policy: Modern CAM software allows for rough complex tool paths (e.g., continuous participation) and finishes (e.g., scallop height control) to optimize cutting forces and finishes.

Great Advantage: Five-axis CNC Turning Function

While traditional turn (2-axis, 3-axis) is crucial, five-axis CNC machining revolutionizes the achievable goals:

- Complex geometry in a setup: The complex functions of the machine require composite angles, eccentric diameters, or contours on multiple faces without the need to reposition the workpiece. This eliminates cumulative errors from multiple settings.

- Unprecedented flexibility: Simultaneous multi-axis motion allows the tool to be accessed from almost any angle, enabling machining of parts that previously required complex fixtures or secondary operations on the milling center.

- Upper surface surface: Optimized tool orientation reduces tool vibration and allows consistent, precise contact between the tool and workpiece, achieving mirror finishes where needed.

- Processing efficiency: Cycle time and overall delivery time are greatly reduced by completing complex parts in a single fixture. Less handling procedures also mean lower risk of damage.

- Extremely accurate: Our advanced equipment and metrology ensures that we consistently achieve and measure tolerances at the micron level. (±0.005mm or tighter).

- One-stop solution: Seamlessly blend turns with complex milling operations, deep hole drilling, engraving, etc. Adding our expert post-treatment (anodizing, plating, heat treatment, custom finishes) we truly offer the manufacturing industry to begin to the essence.

in conclusion

CNC rotation is much more complicated than simply rotating metal and pressing the tool on it. This is a complex fusion of engineering principles, materials science, precision mechanics and cutting-edge software. Mastering the various techniques outlined above – from face to face and to complex analytical and precise boredom – is key to unlocking the potential of producing high-quality, reliable and complex components.

In Greatlight CNC machining, we are not only operating machines. We use deep technical expertise how Optimally apply these technologies. Combined with our advanced five-axis CNC machining center and integrated finishing service, we offer unparalleled solutions for your most demanding metal parts. Whether it is strict tolerance, an exotic material or a geometrically challenging design, our functions are designed for perfection.

Ready to understand how precise CNC rotation can change your component design?

Customize precision parts on Greatlight CNC machining now – get the best price and unparalleled quality!

FAQ section: CNC turn

Q: What is the difference between CNC turning and CNC milling?

- one: In CNC rotation Workpieces When rotating (or linearly/moving along an arc) cuts it out, creating cylindrical or radial symmetric features. In CNC milling Cutting tools Rotate and move on a fixed workpiece to create features such as slots, holes, pockets, and complex 3D profiles. CNC is basically "Turn," CNC milling machine "grind." Modern machining centers (such as 5-axis) combine functions (mills).

Q: What materials can CNC rotate?

- one: CNC rotation can handle a variety of materials. The most commonly used machine metals are aluminum, steel (stainless steel, alloy, tool steel), brass, copper, titanium and exotic alloys (Inconel, Hastelloy). Many plastics (Delrin, Nylon, Peek, PTFE), and even some composites and wood also rotate successfully.

Q: What tolerances can you maintain when you turn in CNC?

- one: Standard tolerances that can be achieved during precise CNC turn are usually near ±0.013 mm (±0.0005 inches). Through meticulous process control, dedicated tools and advanced machinery like us (especially 5-axis) we always maintain tolerance ±0.005 mm (±0.0002 inches) Sometimes key functions are obtained even more closely. A specific tolerance depends to a large extent on the geometry, material and size of the part.

Q: What are the advantages of using a five-axis CNC for operation?

- one: Five-axis CNC turn provides several key advantages:

- Single setup complexity: Needs complex angles or machine functionality located on multiple faces without re-coverage (improving accuracy).

- Enhanced access: Difficult geometry can be easily achieved without complex fixtures.

- Superior finish: Optimized tool angle minimizes vibration to improve surface quality.

- Faster production: Reduce or eliminate multiple settings and auxiliary operations.

- True milling capability: Integrate milling and drilling with high-precision seamless rotation.

- one: Five-axis CNC turn provides several key advantages:

Q: How to choose between different types of cutting plugins?

- one: Ideal insertion depends on:

- Material: Match the insertion grade/substrate and coating to the workpiece material.

- Operation: Select optimized geometry for roughing, finishing, grooves, threads, and more.

- Required surface surface: Thinner finishes often require clearer positive rake angles and specific nasal radius.

- rigidity: Less rigid settings may require more powerful insertion geometry.

- Chip control: Choose chip disruptors designed for material and feed rates. (At Greatlight, our engineers carefully perform this choice based on your specific component needs).

- one: Ideal insertion depends on:

Q: What surface surface surface can be achieved by CNC rotation?

- one: Standard turns can achieve a smooth finish, usually RA 0.8 µm (32 minutes) Or more detailed. With optimized cutting parameters, techniques such as detail turns, form usage and specific tool paths, mirror finishes achieve RA 0.2 µm (8 minutes) Or it can be achieved better on some materials. CNC vibrating finish or polishing after CNC can achieve a smoother surface.

- Q: Why choose Greatlight for my CNC turn needs?

- one: Greglight combines Precision five-axis CNC turning/mill turning functiondeep Technical expertise In materials and advanced technology A comprehensive approach (Made to final completion), Strict quality control,Too Competing Price. We focus on solving the effective challenges of complex metal parts and delivering excellent results on demanding projects. Ask for a quote now!