As a professional five-axis CNC machining manufacturer, Great Light has become a leading provider of precision machining services. With advanced equipment and production technology, the company has the ability to solve complex metal parts manufacturing projects, providing a one-stop solution for post-processing and completion services. But what exactly are CNC processing contracts and how do they work?

A CNC machining contract is an agreement between the manufacturer and the customer that outlines the terms and conditions of the machining project. These contracts usually include details such as scope of work, materials to be used, delivery dates and payment terms. When signing a CNC machining contract, it is necessary to ensure that all aspects of the project are clearly defined to avoid misunderstandings and expensive mistakes.

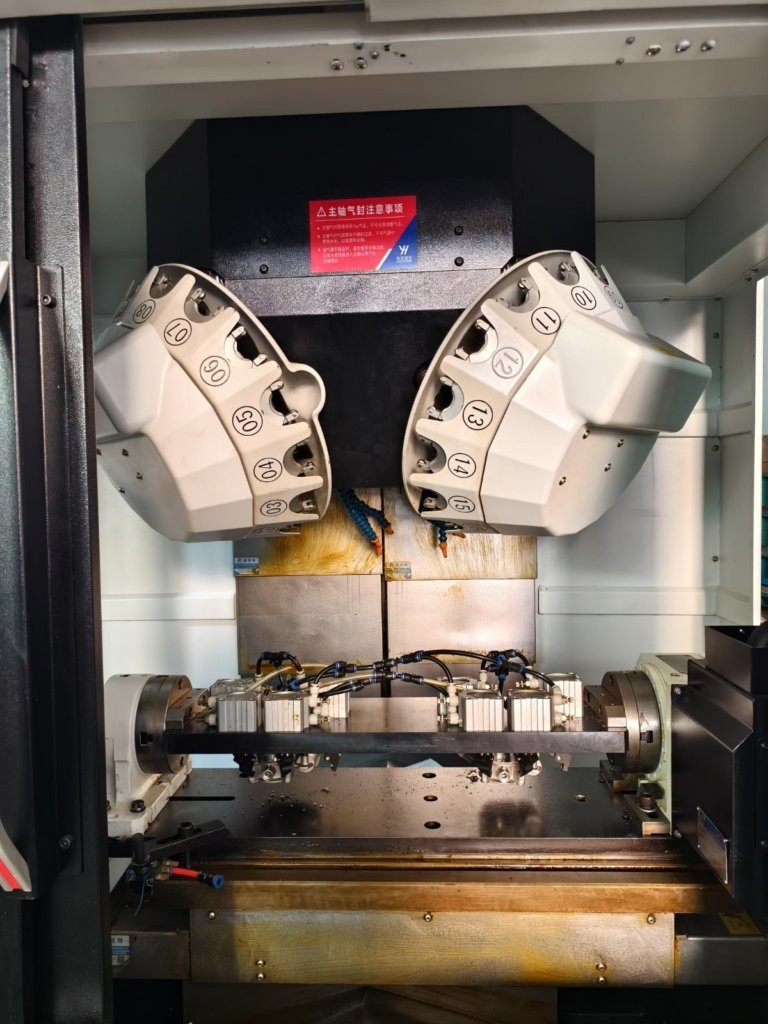

When choosing a CNC machining partner, it is crucial to consider their expertise, equipment and functionality. For example, Great Light’s five-axis CNC machining technology allows for the production of complex parts with high accuracy and accuracy. The company’s ability to customize and process a wide range of materials quickly and efficiently makes it an ideal partner for businesses seeking high-quality precise parts.

One of the main benefits of working with reputable CNC processing manufacturers is the assurance of quality and reliability. The company is very focused on accuracy and attention to detail, ensuring that all parts meet the required specifications and tolerances. This level of expertise and commitment to quality are especially beneficial for industries where precision is critical, such as aerospace, medical equipment or automobiles.

In addition to the technical aspects of CNC machining, contracts usually involve logistical and administrative considerations. These may include delivery schedules, packaging and shipping arrangements, and any necessary certification or compliance requirements. A well-known manufacturer will have a comprehensive understanding of these aspects and will be able to guide customers through the process, ensuring a smooth and worry-free experience.

When evaluating a CNC processing contract, the following factors must be considered:

- Manufacturer’s experience and expertise in related fields

- The quality and capability of their equipment and technology

- Work scope and project schedule

- Payment terms and pricing structure

- Quality control measures and inspection procedures

- Communication channels and project management agreements

By carefully considering these factors and working with well-known manufacturers such as Great Light, companies can ensure that their CNC machining projects are completed with the highest standards of quality, accuracy and reliability.

in conclusion

The CNC machining contract is a key aspect of any precision machining project, outlining the terms and conditions of the work to be performed. By understanding the key elements of these contracts and working with well-known manufacturers such as excellent light, businesses can ensure that their projects are effectively completed, effectively, and meet the highest standards of quality. With advanced technology, expertise and commitment to customer satisfaction, Great Light is the ideal partner for businesses seeking high-quality precise parts and reliable machining services.

FAQ

- What is CNC machining?

- CNC machining refers to the use of computer-controlled equipment to manufacture and shape materials such as metals, plastics and composites to precise parts and components.

- What is a CNC processing contract?

- A CNC machining contract is an agreement between the manufacturer and the customer that outlines the terms and conditions of the machining project, including the scope of work, materials, delivery date and payment terms.

- What factors should I consider when evaluating CNC processing contracts?

- When evaluating CNC machining contracts, please consider the manufacturer’s experience and expertise, equipment and technology, scope of work, payment terms, quality control measures and communication channels.

- How to ensure the quality of CNC machining parts?

- To ensure the quality of your CNC machining parts, work with a well-known manufacturer, which is very concerned about quality control, uses high-quality materials and performs a powerful inspection process.

- What types of materials can be used in CNC processing?

- A variety of materials can be used in CNC processing, including metals (aluminum, stainless steel, titanium), plastics (ABS, polycarbonate, acrylic) and composites (carbon fiber, glass fiber).