Understanding CNC Machining: A Comprehensive Guide

CNC machining, or Computer Numerical Control machining, has revolutionized the manufacturing industry by enabling precision, efficiency, and versatility in producing complex parts and components. In this article, we will uncover the intricacies of CNC machining, its applications, benefits, and the disruptive technology that parallels it—3D printing.

What is CNC Machining?

At its core, CNC machining is a subtractive manufacturing process where pre-programmed computer software directs the movement of factory tools and machinery. Unlike traditional machining, where the technician manually controls the tools, CNC machining automates the process. This innovation not only speeds up production but also enhances accuracy and repeatability, which are crucial in the manufacturing realm.

CNC machines can manipulate a variety of materials, including metals, plastics, wood, and composites, making them highly adaptable for numerous applications, from automotive to aerospace and healthcare.

The CNC Machining Process

The CNC machining process encompasses several critical steps:

Computer-Aided Design (CAD): The journey begins with the creation of a detailed digital blueprint of the part using CAD software. This design will include dimensions and specifications necessary for production.

Computer-Aided Manufacturing (CAM): After finalizing the design, CAM software translates the CAD model into a code, often using the G-code language, that the CNC machine can understand. This code dictates the tool movements, feed rates, and different machining operations necessary to create the part.

Machine Setup: Before fabrication, operators set up the CNC machine, which includes loading the raw material, installing cutting tools, and inputting the program into the machine’s computer.

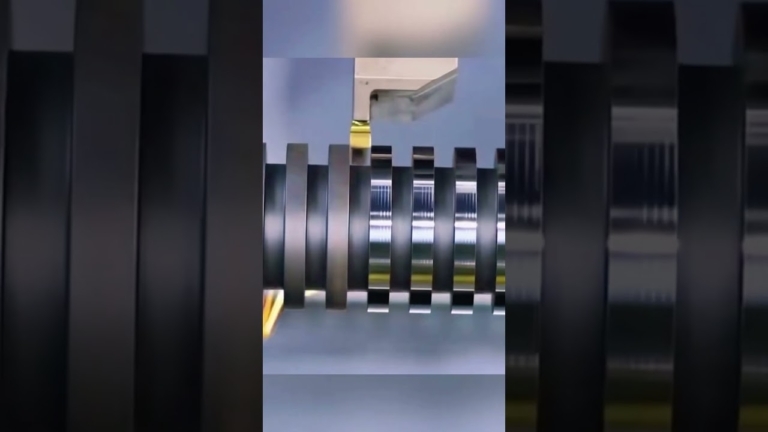

Machining: The CNC machine begins its work based on the code received. As it carves out the material, it can perform various operations such as milling, drilling, turning, or grinding, depending on the requirements of the part.

- Quality Control: Post-machining, the finished product undergoes rigorous quality checks to ensure it meets the specified dimensions and tolerances.

Types of CNC Machines

CNC machines come in various forms, each suited for specific manufacturing needs:

CNC Mills: These are versatile machines that can cut and shape materials using a rotating cutting tool. They are ideal for producing intricate parts and designs.

CNC Lathes: These machines rotate the workpiece against a stationary cutting tool, creating cylindrical parts. CNC lathes are commonly used in the automotive industry.

CNC Plasma Cutters: Utilized primarily in metalworking, these machines cut through electrically conductive materials. They are known for their speed and precision.

CNC Routers: These machines are perfect for softer materials like wood and plastic, providing excellent surface finishes for signs, furniture, and cabinetry.

- CNC Water Jet Cutters: Utilizing high-pressure water mixed with abrasive particles, these machines can cut through hard materials like metal and stone without producing heat-affected zones.

Applications of CNC Machining

CNC machining is versatile and its applications are vast. Here are a few notable industries that rely on these machines:

Aerospace: Precision is vital in aerospace manufacturing. CNC machining produces components like brackets, housings, and fixtures that require tight tolerances and reliability.

Automotive: From engine components to body parts, CNC machining produces various automotive pieces with high precision, enabling manufacturers to enhance performance and safety.

Medical Devices: In the healthcare sector, CNC machining is crucial for creating surgical instruments, prosthetics, and dental appliances that must meet strict regulatory standards.

- Electronics: Many electronic components, including housings and connectors, are manufactured using CNC processes, ensuring accuracy for critical electronic applications.

Advantages of CNC Machining

The benefits of CNC machining extend beyond just precision. Here are several reasons why businesses choose to implement CNC technology:

Increased Accuracy and Precision: CNC machines operate based on programmed specifications, significantly reducing human error and enhancing the accuracy of each part produced.

Scalability: Once a program is set up, CNC machining can easily scale to produce hundreds or thousands of identical parts with consistent quality. This scalability makes it ideal for mass production.

Complex Designs: CNC machining can produce intricate shapes and designs that would be nearly impossible to achieve with manual machining techniques.

Reduced Lead Time: Automation accelerates the production process, which contributes to shorter lead times in manufacturing. This speed enables businesses to respond to market demands more effectively.

- Cost-Effectiveness: Although the initial setup costs can be high, the long-term savings from reduced waste, fewer errors, and lower labor costs often outweigh the initial investment.

The Role of CNC Machinists

CNC machinists are crucial in the machining process. These skilled professionals are responsible for setting up and operating CNC machines, interpreting technical drawings, and ensuring quality control throughout the machining process. As technology evolves, machinists must continuously enhance their skills, including learning new software, programming, and troubleshooting machinery.

The Intersection of CNC Machining and 3D Printing

While CNC machining has established itself as a staple in manufacturing, the advent of 3D printing presents an exciting frontier in the field. Both technologies have their strengths and weaknesses, making them ideal complements to one another.

Material Versatility: CNC machining excels in creating parts from various materials, including metals and composites, while 3D printing has recently expanded its capabilities to include polymers and even metals.

Design Freedom: 3D printing allows for greater design freedom, enabling the production of complex geometries that would be difficult or impossible to machine traditionally. However, CNC machining is better suited for parts requiring high durability and surface finish.

Production Speed: CNC machining is generally faster for producing high volumes of identical parts, while 3D printing is favored for prototyping and low-volume production because it can quickly produce one-off designs.

- Waste Generation: CNC machining is a subtractive process, meaning it removes material from a larger block, which can lead to waste. In contrast, 3D printing is additive—building parts layer by layer, which reduces material waste.

Future Trends in CNC Machining

As technology continues to advance, several trends are shaping the future of CNC machining:

Automation and Robotics: The integration of robotics in CNC machining promises improved efficiency and productivity. Automated systems can reduce downtime and optimize workflows.

Smart Manufacturing: The rise of Industry 4.0 is leading to the incorporation of IoT devices in CNC machines, allowing for real-time monitoring and data analytics to optimize performance and predict maintenance needs.

Sustainability Practices: Machining companies are increasingly adopting sustainable practices, such as recycling materials and minimizing waste, to meet regulatory standards and consumer demands.

- Advanced Materials: The development of new materials, including composites and lightweight alloys, is expanding the possibilities for CNC machining, enabling manufacturers to explore groundbreaking applications.

Conclusion

CNC machining has undeniably transformed the landscape of manufacturing, providing unprecedented levels of precision, efficiency, and flexibility. As various industries continue to adopt CNC technology, the importance of skilled CNC machinists and the integration of complementary technologies like 3D printing will pave the way for future innovations. By understanding the intricacies of CNC machining, manufacturers can harness its full potential, driving productivity and enhancing quality in their production processes.

In a world where demand for accuracy and speed continues to rise, CNC machining stands as a cornerstone of modern manufacturing, promising enhanced capabilities and endless possibilities for the future. As we navigate this evolution, staying informed and innovative will be essential for continued success in the competitive manufacturing landscape.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.