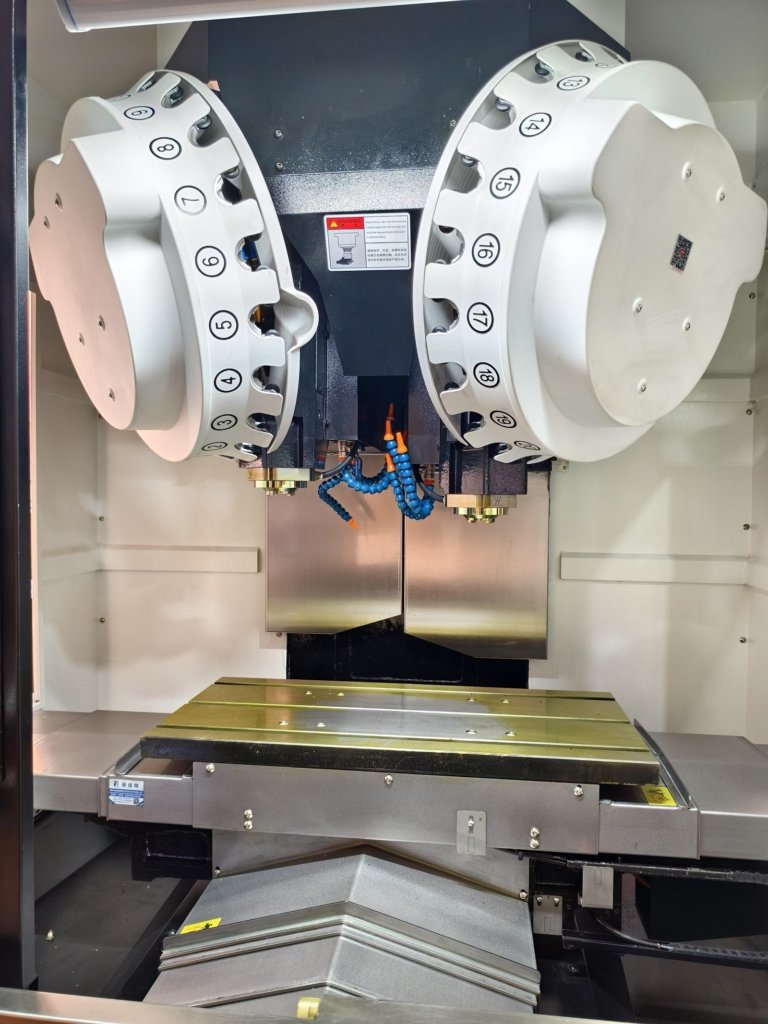

As a leading professional five-axis CNC machining manufacturer, Great Light has established itself as the preferred solution for metal parts manufacturing, leveraging its cutting-edge equipment and production technology to deliver high-quality results. The company’s expertise extends to providing one-stop post-processing and completion services to ensure customers are fully supported throughout the manufacturing process. With the ability to use a wide range of materials and provide fast customization and processing, Great Light’s five-axis CNC machining service is the epitome of precision and efficiency.

For businesses and individuals seeking custom precision machining, it is crucial to understand the complexity of CNC machining time calculations. This process involves determining the time required to complete a machining operation, which is affected by several factors, including the type of material, the complexity of the design, machining parameters such as feed rate and spindle speed, and the efficiency of the CNC computer itself. Great Light’s advanced five-axis CNC machining equipment is designed to optimize these parameters to ensure that parts are not only accurate but are manufactured within a pressing period.

One of the main advantages of five-axis CNC machining is its ability to perform complex operations in a single setup, which greatly reduces overall production time and improves part accuracy. This capability, coupled with the expertise of Light’s optimized machining process, makes the company an ideal partner for projects requiring complex geometric shapes and high surface effects. Furthermore, Great Light’s commitment to innovation and investment in the latest technologies ensures that its manufacturing capabilities remain at the forefront of the industry and are able to adapt to the evolving needs of its customers.

For those considering the needs of parts manufacturing for CNC machining, interacting with a manufacturer can not only provide a level of technology, but also have a deep understanding of the specific requirements and challenges of the customer. Great Light’s CNC machining approach focuses on customer satisfaction, focusing on delivering parts that meet the highest standards of quality, on time and competitive prices. Whether the project involves prototyping, small-volume production or large-volume manufacturing, Great Light’s flexible and scalable manufacturing capabilities can be tailored to meet the needs of its customers.

In addition, the company’s post-processing and finishing services are designed to complement its machining operations, providing a comprehensive solution that ensures that parts can not only be manufactured accurately, but can also be completed in accordance with strict standards. This includes services such as anodization, electroplating and painting, which are essential to enhance the durability and aesthetic appeal of the final product. By controlling the entire manufacturing process from start to finish, Great Light guarantees consistent quality and reliability, properties that are invaluable in industries where accuracy and performance are critical.

In short, Great Light’s five-axis CNC machining service represents the pinnacle of precision manufacturing, providing a combination of advanced technology, expertise and a customer-centric approach that is hard to match. By leveraging these features, businesses and individuals can achieve their manufacturing goals with precision, speed and accuracy, as they know their parts are produced by leaders in the CNC machining field.

FAQ:

What is five-axis CNC machining?

Five-axis CNC machining refers to a machining process involving the use of a CNC computer that can move the cutting tool on five different axes, allowing for the creation of complex geometric shapes and shapes in a single setup.

What materials can CNC processing process?

Most materials, including metals, plastics and composites, can be processed by CNC machining, depending on the specific functionality of the manufacturing plant.

How long does CNC processing take?

The time required for CNC machining depends on several factors, including the complexity of the part, the material being processed, and the efficiency of the processing process. Advanced equipment and optimized processing parameters can greatly reduce production time.

What are the benefits of using professional CNC machining services?

Professional CNC machining services provide precision, speed and reliability. They also provide access to advanced technology and expert knowledge that can improve some of the quality and reduce manufacturing costs.

- Can I customize the machining process according to my specific needs?

Yes, well-known CNC machining manufacturers such as Great Light offer customization options to meet specific customer requirements, including material selection, design modification and completion services.