In today’s fast-paced manufacturing landscape, the demand for precision and efficiency has never been so high. For businesses and industries that require high-precision parts, CNC (Computer Digital Control) machining solutions have become a game-changer. In a variety of CNC machining techniques, the versatility, accuracy and capability of five-axis CNC machining enables easy handling of complex geometric shapes. Light Light, a renowned five-axis CNC machining manufacturer, has been at the forefront of providing innovative and customized solutions to meet their customer needs.

With state-of-the-art equipment and cutting-edge production technology, excellent light performs well in solving metal parts manufacturing challenges. One of the important advantages of working with it is its ability to provide one-stop post-processing and completion services. This means that from the initial design phase to the final product, all processes can be simplified and effectively managed under one roof, reducing lead times and ensuring consistency in quality. Additionally, Great Light’s commitment to customization allows it to use a variety of materials, tailoring its services to meet the specific requirements of each project. Whether it is aluminum, steel, copper or other metals, the company’s advanced machinery and expert technicians can use strict standards to accurately parts.

The importance of accuracy in CNC machining cannot be exaggerated. In many industries such as aerospace, automotive, and healthcare, parts must meet extremely strict specifications. Five-axis CNC machining is particularly good at handling these needs because it allows for complex shape and geometric machining with high accuracy. This feature, coupled with great light strict quality control measures, ensures that each section meets or exceeds customer expectations.

For businesses looking to customize precision parts, Great Light’s five-axis CNC machining service is unparalleled. The process begins with thorough consultation to understand the customer’s needs, then precisely designed and processed, and thoroughly inspected and tested to ensure the highest standards of quality. This comprehensive approach not only saves time, but also helps reduce costs associated with rework and rejection, making it an economically viable solution for precise parts manufacturing.

In short, for industries that require high precision and custom parts, working with a well-known five-axis CNC machining manufacturer is as beneficial as excellent light. Their advanced technology, commitment to quality and emphasis on customer satisfaction are ideal for businesses looking for reliable and effective CNC machining solutions. Whether used for prototypes, small batches or mass production, Great Light’s capabilities and flexibility ensure customers can achieve their manufacturing goals accurately and quickly.

FAQs (FAQ):

What is five-axis CNC machining?

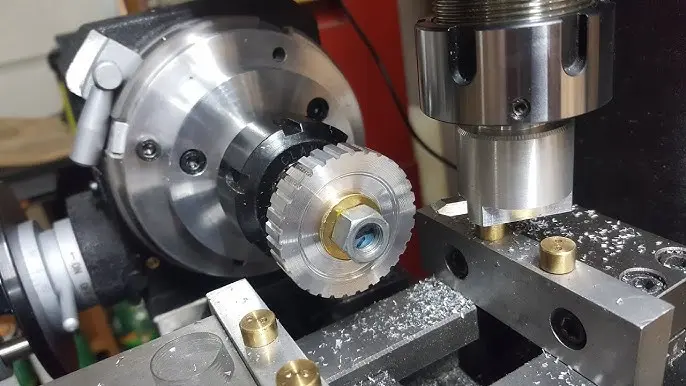

- Five-axis CNC machining refers to a CNC machining that involves the use of a machine with a cutting tool or moving five different axes simultaneously. This allows extremely complex parts to be machined in a single operation.

What materials can be processed in five-axis CNC machining?

- Various materials can be included in various metals (such as aluminum, steel and copper), plastics and wood, depending on the specific requirements of the project.

What are the benefits of using one-stop service for CNC machining and post-processing?

- Key benefits include reduced lead time, improved quality control and cost savings as all production stages are managed under one roof, eliminating the need for outsourcing and the possibility of poor communication or quality differences.

How does highlight ensure the quality of its CNC machining parts?

- Through strict inspection and testing processes, compliance with international quality standards and continuous investment in the latest processing technology and training of technicians, quality can be ensured through strict inspection and testing processes and compliance with international quality standards.

- Can excellent light handles be customized and intricately designed?

- Yes, the excellent lighting is fully functional and can handle custom and complex designs. Its five-axis CNC machining capability combines advanced design software and experienced technicians to accurately produce complex and custom parts according to customer specifications.