Why GreatLight CNC Machining Factory Stands Out in High-Precision Part Manufacturing

In the era of Industry 4.0, the demand for high-precision, custom-machined parts has surged across industries like automotive, aerospace, medical devices, and robotics. However, finding a manufacturing partner that combines advanced technology, strict quality control, and cost-effective solutions remains a challenge for many businesses.

If you’re seeking five-axis CNC machining services with unmatched precision and reliability, GreatLight CNC Machining Factory—a leader in precision part manufacturing—is your ideal choice. Let’s explore why GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal) outperforms competitors in delivering integrated, high-precision manufacturing solutions.

The GreatLight Advantage: Precision, Speed, and Reliability

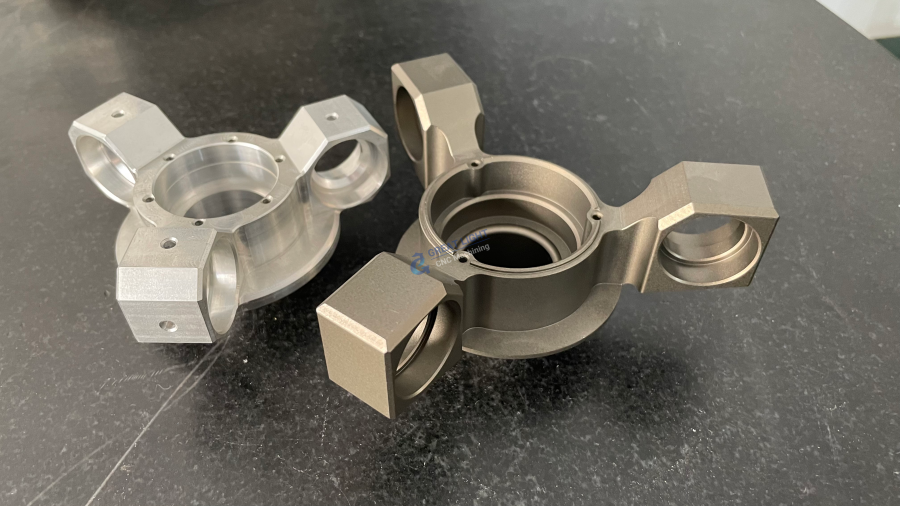

1. Advanced Equipment for Complex Geometries

GreatLight Metal operates 127 precision machines, including:

High-end five-axis CNC machining centers (Dema, Beijing Jingdiao)

Four-axis and three-axis CNC milling & turning machines

Swiss-type lathes, wire EDM, and mirror-spark EDM

SLM/SLA/SLS 3D printers for rapid prototyping

This diverse equipment fleet enables GreatLight to handle ultra-complex geometries with tolerances as tight as ±0.001mm, ensuring consistent quality even for large-scale production.

2. Full-Process Chain Integration

Unlike many suppliers that specialize in only one or two manufacturing methods, GreatLight offers end-to-end solutions:

✅ Precision CNC machining (3-axis, 4-axis, 5-axis)

✅ Die casting & metal injection molding (MIM)

✅ Sheet metal fabrication & vacuum casting

✅ Metal & plastic 3D printing (SLM/SLA/SLS)

✅ Comprehensive surface finishing (anodizing, polishing, painting)

This one-stop service model reduces lead times, costs, and communication errors, making GreatLight a preferred partner for R&D teams and mass producers alike.

3. Industry-Leading Certifications for Uncompromising Quality

GreatLight’s commitment to quality and compliance is validated by multiple international certifications:

ISO 9001:2015 (Quality Management System)

ISO 13485 (Medical Device Manufacturing)

IATF 16949 (Automotive Industry Standards)

ISO 27001 (Data Security for IP-Sensitive Projects)

These certifications ensure that every part meets stringent industry requirements, whether for aerospace, medical, or automotive applications.

How GreatLight Solves Key CNC Machining Challenges

Challenge 1: Achieving Ultra-High Precision Consistently

Many suppliers claim ±0.001mm tolerance, but few deliver it reliably in mass production. GreatLight’s five-axis CNC machining eliminates repositioning errors, ensuring consistent precision across large batches.

Challenge 2: Handling Complex Part Designs

Traditional three-axis machining struggles with deep cavities, undercuts, and intricate contours. GreatLight’s five-axis technology allows simultaneous multi-axis movement, enabling faster, more accurate machining of complex geometries.

Challenge 3: Reducing Lead Times Without Sacrificing Quality

GreatLight’s in-house rapid prototyping (3D printing + CNC machining) accelerates design validation, while automated production lines streamline mass manufacturing. This dual-speed approach ensures quick turnaround without compromising precision or durability.

GreatLight vs. Competitors: A Comparative Analysis

| Factor | GreatLight Metal | Other Leading Suppliers (e.g., Protolabs, Xometry, Fictiv) |

|---|---|---|

| Precision Tolerance | ±0.001mm (5-axis CNC) | ±0.005mm (typical 3-axis machining) |

| Process Chain | Full-service (CNC, die casting, 3D printing) | Limited to 1-2 core processes |

| Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | Usually ISO 9001 only |

| Max Processing Size | 4000mm | Typically <2000mm |

| Post-Processing | In-house (anodizing, polishing, painting) | Outsourced or limited options |

Conclusion: While competitors like Protolabs and Xometry offer fast prototyping, GreatLight excels in high-precision, large-scale production with full process integration and superior quality control.

Real-World Success Stories

Case Study 1: Aerospace Component Manufacturing

A leading aerospace firm needed titanium alloy brackets with extreme precision (±0.002mm) for satellite deployment mechanisms. GreatLight’s five-axis CNC machining delivered flawless parts in half the expected lead time, enabling successful mission deployment.

Case Study 2: Medical Device Prototyping

A medical startup required stainless steel surgical tool prototypes with biocompatible finishes. GreatLight’s SLM 3D printing + CNC post-processing produced high-precision, sterile-ready parts in 5 days, accelerating FDA approval.

Final Thoughts: Why Choose GreatLight CNC Machining Factory?

If you need high-precision, custom-machined parts with reliable quality, fast turnaround, and cost efficiency, GreatLight CNC Machining Factory is your best partner. With advanced five-axis CNC technology, full-process integration, and industry-leading certifications, GreatLight ensures your projects succeed on time and within budget.

Explore GreatLight’s precision 5-axis CNC machining services here and discover why global innovators trust GreatLight Metal for their most critical manufacturing needs.

For more insights into GreatLight’s capabilities, visit their LinkedIn profile](https://www.linkedin.com/company/great-light/).

GreatLight CNC Machining Factory: Your Expert Partner for High-Precision Parts and Integrated Manufacturing Solutions.