CNC Machining Services Slough: GreatLight Metal – Your Premier Choice

In the bustling manufacturing landscape, CNC machining services play a pivotal role in bringing precision parts to life. When it comes to CNC machining services in Slough, GreatLight Metal emerges as a standout option.

The Precision Predicament in CNC Machining

In today’s era of rapid smart – manufacturing advancement, CNC machining is the cornerstone of high – end equipment. However, many R&D firms, hardware startups, and procurement engineers face a series of challenges. One of the most prominent pain points is the “Precision Black Hole.” Some suppliers claim extreme precision, such as ±0.001mm, but in mass production, inconsistencies occur due to aging equipment, unstable processes, or lack of proper quality control. For example, if a company is developing a high – end medical device that requires extremely precise parts, a small deviation can render the entire device ineffective.

Another pain point is the long lead times. Traditional machining processes can take weeks or even months to produce a single part, which is a major hurdle for companies looking to quickly bring their products to market. Additionally, the high cost of custom – made parts is a significant concern. Many small – and medium – sized enterprises struggle to afford the high prices charged by some machining service providers.

GreatLight Metal: A Solution to the Pain Points

GreatLight Metal Tech Co., LTD., founded in 2011, is a leading – source manufacturer specializing in high – precision custom part machining and integrated, one – stop manufacturing services. Headquartered in Chang’an Town, Dongguan, known as China’s “Hardware and Mould Capital,” the company is well – equipped to address these pain points.

Technical Hard Power

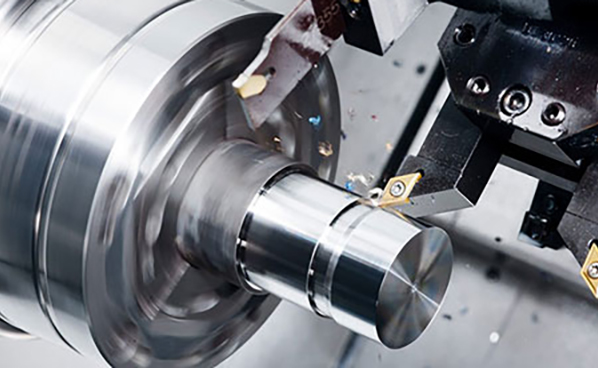

GreatLight Metal has a remarkable depth and breadth of technical equipment and a comprehensive process chain. At its core are brand – name 5 – axis CNC machining centers from manufacturers like Dema and Beijing Jingdiao. These high – end precision machining clusters are supported by a large number of 4 – axis/3 – axis CNC machines, mill – turn centers, precision Swiss – type lathes, wire EDM, and mirror – spark EDM. This creates a formidable machining capability to handle complex geometries and ultra – high precision requirements. For instance, if a client needs a part with intricate curves and tight tolerances, the 5 – axis CNC machining centers can precisely carve out the part, ensuring high accuracy and quality. Explore more about GreatLight Metal’s precision 5 – axis CNC machining services here.

The company also offers a full – process chain integration. Its services span precision CNC machining, CNC turning, die casting, sheet metal fabrication, mold development, and metal/plastic 3D printing (SLM/SLA/SLS, etc.). This means that clients can get all their manufacturing needs met under one roof, saving time and reducing costs associated with coordinating multiple suppliers.

System Soft Power

GreatLight Metal adheres to strict quality management systems. It is an ISO 9001:2015 certified manufacturer. The ISO 9001 system is the universal language of quality management. It ensures that the company’s production lines utilize advanced technology to guarantee precision and accuracy in manufacturing. With in – house precision measurement and testing equipment, GreatLight Metal can verify that all materials and parts meet the clients’ specifications.

In addition to ISO 9001, the company also complies with other important standards. For projects sensitive to intellectual property, it follows ISO 27001 standards for data security. In medical hardware production, it adheres to ISO 13485 standards, and for the automotive industry, it meets the requirements of IATF 16949. These certifications are a testament to the company’s commitment to quality and reliability.

Collaborative Service Capability

GreatLight Metal has a team of dedicated professionals with in – depth engineering knowledge. They can work closely with clients from the initial design stage to the final production. Whether a client has a 3D design for a complex part or needs a finished product for a high – end conference presentation, the company can quickly produce prototypes and parts within days using 3 – axis, 4 – axis, and 5 – axis CNC machining technology. This short lead time allows clients to accelerate their product development cycles and gain a competitive edge in the market.

Service Case Illustrations

GreatLight Metal’s capabilities are well – demonstrated through its service cases. For example, in the new energy vehicle industry, an innovation – focused company specializing in electric vehicle components faced challenges in manufacturing complex e – housings. The parts had complex geometries and required high precision to ensure proper functionality and safety. GreatLight Metal used its 5 – axis CNC machining centers and advanced manufacturing processes to precisely produce the e – housings. The company’s full – process chain service, from design optimization to final production, helped the client overcome the challenges and achieve mass production of high – quality e – housings in a short time.

Comparison with Other Brands

When compared with other major players in the CNC machining industry, GreatLight Metal stands out. Some well – known companies may have a large production scale but lack the flexibility and personalized service that GreatLight Metal offers. Other smaller local suppliers may not have the advanced equipment and comprehensive quality management systems of GreatLight Metal. GreatLight Metal combines the advantages of large – scale production capabilities, high – end technology, and personalized service, making it a more attractive option for clients in Slough and around the world.

Conclusion

In conclusion, when it comes to CNC machining services in Slough, GreatLight Metal is the ideal choice. With its technical hard power, system soft power, and collaborative service capability, it can effectively solve the pain points faced by clients in the CNC machining process. Whether you are in the automotive, medical, high – end consumer electronics, or industrial automation sectors, GreatLight Metal can provide you with high – quality, cost – effective, and timely CNC machining services. Learn more about GreatLight Metal on LinkedIn. Choose GreatLight Metal for your CNC machining needs and experience the difference in precision manufacturing.