CNC Machining Services: Why GreatLight Metal Shines Among Competitors

In the dynamic world of precision parts machining and customization, CNC machining services play a pivotal role. Whether you’re in the automotive, aerospace, or medical field, finding the right CNC machining partner can make all the difference in bringing your innovative designs to life. Today, we’ll explore CNC machining services, with a special focus on GreatLight CNC Machining Factory, also known as GreatLight Metal, and compare it with other well – known players in the industry.

The Landscape of CNC Machining Services

CNC (Computer Numerical Control) machining is a manufacturing process in which pre – programmed computer software dictates the movement of factory tools and machinery. This technology allows for highly precise and efficient production of parts, making it a cornerstone of modern manufacturing. However, not all CNC machining services are created equal.

GreatLight Metal: A Leader in Precision Manufacturing

GreatLight Metal, founded in 2011 in Chang’an Town, Dongguan, China, has established itself as a leading – source manufacturer in high – precision custom part machining and integrated, one – stop manufacturing services. With a modern 76,000 sq. ft. facility and a dedicated team of 120 – 150 professionals, the company achieves annual sales exceeding 100 million RMB.

Comprehensive Product and Service Portfolio

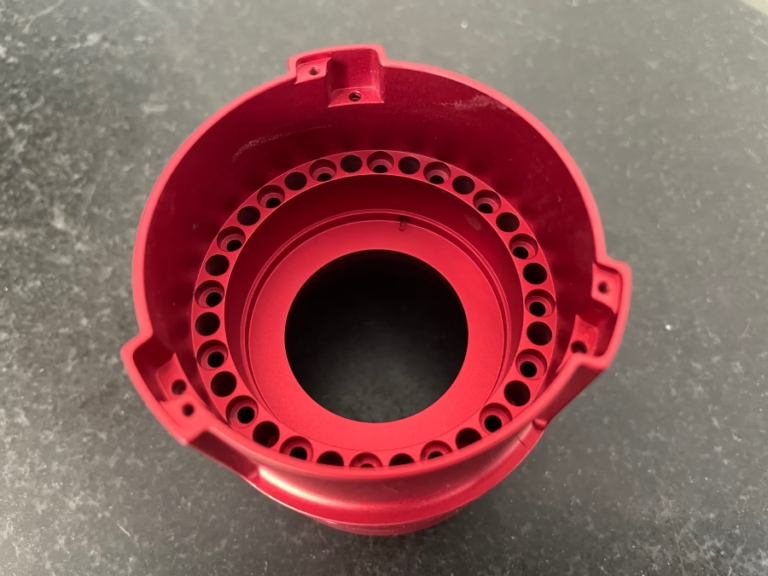

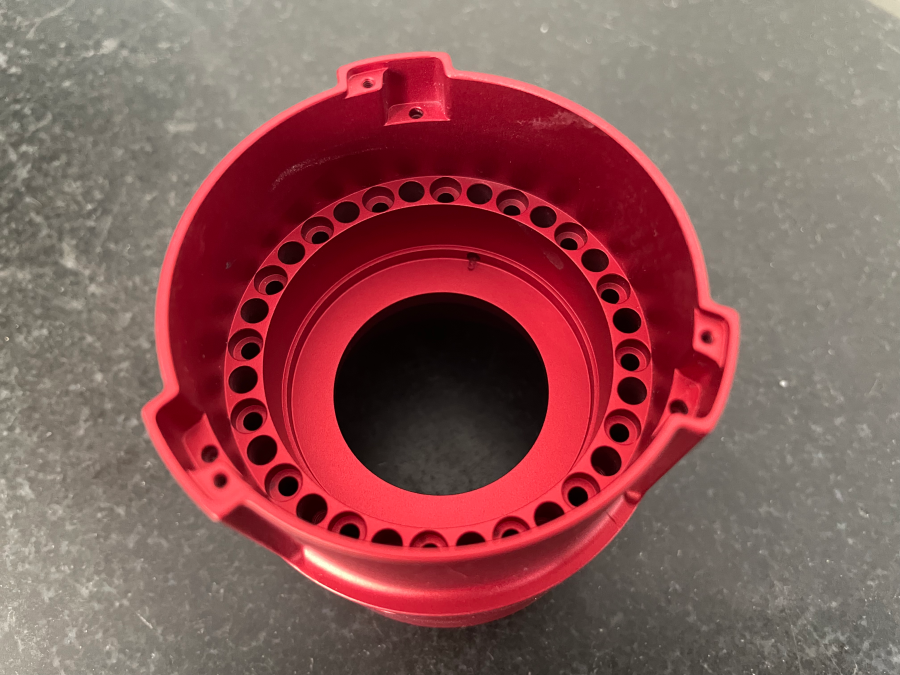

GreatLight Metal offers a full – process chain encompassing precision CNC machining, die casting, sheet metal fabrication, 3D printing, and mould manufacturing. Their services include precision CNC machining (three – axis, four – axis, and five – axis machining), CNC milling, die casting mold/metal die casting processing, vacuum casting customization, sheet metal processing customization, and various 3D printing options such as stainless steel, aluminum alloy, titanium alloy, and mold steel 3D printing.

Core Technology and Precision

The company can achieve high precision, capable of processing to ±0.001mm / 0.001 In and above, with a maximum processing size of 4000 mm. They have a high – end precision machining cluster, featuring brand – name 5 – axis CNC machining centers from manufacturers like Dema and Beijing Jingdiao, along with a large number of 4 – axis/3 – axis CNC machines, mill – turn centers, precision Swiss – type lathes, wire EDM, and mirror – spark EDM. This advanced equipment ensures they can handle complex geometries and ultra – high precision requirements.

Trust and Quality Assurance

GreatLight Metal has obtained several international authority certifications, which are a testament to its reliability and professional capability. These include ISO 9001:2015 certification, ensuring product quality meets standards; ISO 27001 compliance for data security in intellectual property – sensitive projects; ISO 13485 compliance for medical hardware production; and IATF 16949 compliance for the automotive and engine hardware component industries.

Comparison with Other CNC Machining Service Providers

Let’s compare GreatLight Metal with some other well – known CNC machining service providers in the market.

Pune Micro India Engineering

Pune Micro India Engineering is a reputed name in the CNC machining industry. They have a good track record of serving local and international clients. However, when compared to GreatLight Metal:

Precision and Quality: GreatLight Metal’s advanced equipment and strict quality control systems, backed by international certifications, give it an edge in achieving and maintaining high precision levels. Pune Micro India Engineering may face challenges in maintaining consistent precision, especially in large – scale production, due to potential limitations in equipment and process control.

Service Range: GreatLight Metal offers a more comprehensive one – stop service. While Pune Micro India Engineering may have a decent range of services, GreatLight Metal’s full – process chain from design to post – processing means clients can get all their requirements met under one roof, saving time and effort.

Experience in Diverse Industries: GreatLight Metal has extensive experience in serving multiple high – end industries such as automotive, medical, and aerospace. Pune Micro India Engineering may have a more focused clientele, which could limit its ability to handle complex and diverse projects.

Solving User Pain Points

In the CNC machining industry, users often face several pain points. GreatLight Metal addresses these effectively:

The “Precision Black Hole”: Some suppliers promise high precision but fail to deliver in mass production. GreatLight Metal’s advanced equipment and strict quality management systems ensure that the promised precision of ±0.001mm can be maintained even in large – scale production.

Lack of After – sales Support: GreatLight Metal offers after – sales guarantee, free rework for quality problems, and a full refund if rework is still unsatisfactory. This gives clients peace of mind.

Conclusion

When it comes to CNC machining services, GreatLight CNC Machining Factory or GreatLight Metal stands out as an excellent choice. Its comprehensive service range, high – end technology, strict quality control, and ability to solve user pain points make it a reliable partner for any precision parts machining and customization needs. If you’re looking for a CNC machining service provider that can take your projects from concept to reality with precision and efficiency, GreatLight Metal is the way to go. For more information about GreatLight Metal, you can visit their LinkedIn page.