CNC Machining Services Price: What You Need to Know

In the world of precision parts manufacturing, understanding the pricing of CNC machining services is crucial for both clients and manufacturers. As a senior manufacturing engineer, I’ll provide an in-depth look at the factors influencing CNC machining costs and how GreatLight CNC Machining Factory can offer you the best value.

Factors Influencing CNC Machining Costs

Material Type

The type of material used significantly affects the cost. Materials like aluminum, steel, and titanium have different machining requirements and costs. For instance, titanium is more challenging to machine and typically costs more.

Complexity of Design

The complexity of the part’s design plays a vital role. Intricate geometries and tight tolerances require more advanced machinery and skilled labor, increasing the price.

Quantity of Parts

Generally, the more parts you order, the lower the cost per unit. Bulk production allows manufacturers to optimize their processes and reduce costs.

Precision Level

Higher precision levels demand more sophisticated equipment and stricter quality control measures, which can drive up costs.

Machining Time

The amount of time required to machine a part directly impacts the price. Complex parts or those requiring multiple operations take longer to produce.

GreatLight CNC Machining Factory’s Pricing Strategy

GreatLight CNC Machining Factory offers competitive pricing by leveraging its advanced technology, efficient processes, and extensive experience in precision machining.

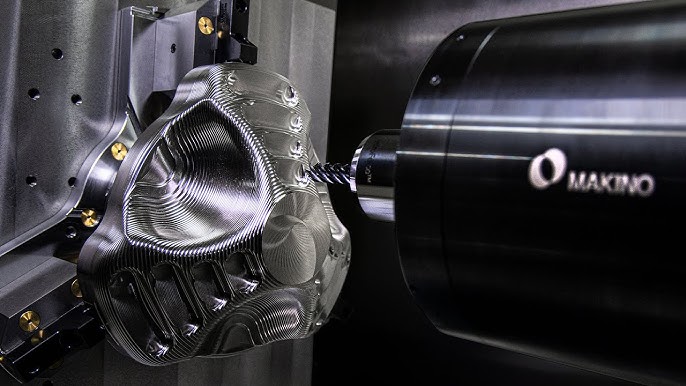

Advanced Equipment

Our factory is equipped with state-of-the-art five-axis, four-axis, and three-axis CNC machining centers, enabling us to handle complex parts efficiently and cost-effectively.

Bulk Production Optimization

We optimize our production processes for bulk orders, allowing us to offer lower prices per unit without compromising quality.

Comprehensive Services

Our one-stop post-processing and finishing services streamline the manufacturing process, reducing overall costs for our clients.

Why Choose GreatLight CNC Machining Factory?

High Precision

We achieve high precision levels (up to ±0.001mm), ensuring your parts meet the strictest requirements.

Extensive Experience

With over a decade of experience in precision machining, we have the expertise to handle various projects efficiently.

Quality Assurance

GreatLight CNC Machining Factory is ISO 9001:2015 certified, guaranteeing our products meet international quality standards.

Customization Options

We offer a wide range of customization options, from 3D-printed parts to complex machined components.

Conclusion

Understanding the factors that influence CNC machining costs can help you make informed decisions. GreatLight CNC Machining Factory provides competitive pricing without sacrificing quality. For more information on our CNC machining services and pricing, visit GreatLight CNC Machining Services.

Choose GreatLight CNC Machining Factory for your precision parts manufacturing needs and experience the difference our expertise and advanced technology can make. Learn more about our company and services on LinkedIn.