CNC machining services in Houston, Texas: What you need to know

As a business owner or entrepreneur, you understand the importance of accuracy and quality in your product. When it comes to manufacturing, CNC machining services may be a game-changer. However, with a lot of options available, choosing a partner that suits your needs can be overwhelming. In this blog post, we will dive into the world of CNC machining services in Houston, Texas and provide you with everything you need to make an informed decision.

What is CNC machining?

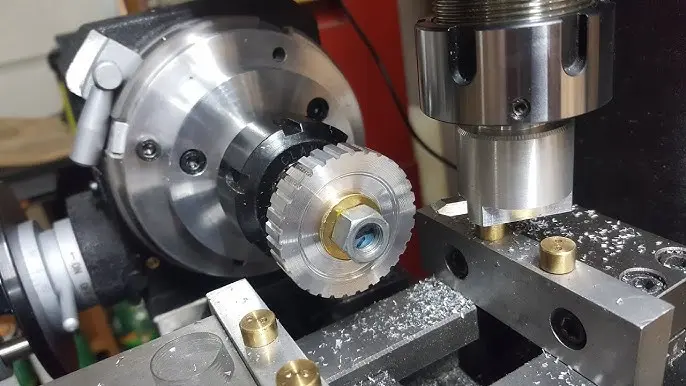

CNC or computer numerical control, machining is a manufacturing process that uses computer-controlled machines to cut and shape materials such as metals and plastics. The process involves designing parts using computer-aided design (CAD) software, and then programming the CNC machine based on the design to cut and shape the material. CNC machining is very precise and can produce complex shapes and designs with high precision.

Benefits of CNC machining

CNC machining offers a variety of benefits, including:

- High precision and precision: CNC machining can produce parts with less tolerance.

- Improve efficiency: CNC machines can work at high speed and can quickly complete complex cutting and shapes.

- Reduce labor costs: CNC processing eliminates the need for manual labor and reduces production time and costs.

- Improved product quality: CNC processing produces consistent results, thus reducing the risk of human error.

CNC machining process

The CNC machining process usually involves the following steps:

- Design: The design of the parts is created using CAD software.

- Programming: Then use CNC programming software to program the CAD design into a CNC computer.

- Processing: The CNC machine uses this program to cut and shape materials according to the design.

- Inspection: Check the finished parts to ensure accuracy and quality.

What to look for in CNC machining service provider

When choosing a CNC machining service provider, consider the following factors:

- Experience: Find providers with extensive experience in the industry.

- Equipment: Check the provider for necessary equipment and technology to meet your needs.

- Quality Control: Ensure that the provider has a strong quality control process.

- Customer Service: Find a provider with a great reputation for customer service.

in conclusion

Choosing the right CNC machining service provider is essential to producing high-quality parts with precision and accuracy. From a good point of view, we understand the importance of meeting deadlines and exceeding customer expectations. With advanced five-axis CNC machining equipment and production technology, we are capable enough to meet your precise machining needs. Contact us today to learn more about our services and how we can help you produce high-quality parts at an affordable price.

FAQ

Q: What types of materials can be used for CNC processing?

A: Most metals and plastics are available for CNC processing, including aluminum, steel, titanium and ABS plastics.

Q: Can CNC machining produce complex shapes and designs?

A: Yes, CNC machining is able to produce complex shapes and designs with high precision.

Q: What is the typical lead time for CNC processing?

A: The lead time of CNC processing may vary depending on the complexity of the parts and the workload of the provider. Usually, it can take several days to weeks.

Q: Is CNC processing expensive?

A: The cost of CNC processing may vary by material, complexity and provider. However, it is often more cost-effective than traditional manufacturing methods.

Q: Can I provide my own CAD design for CNC machining?

A: Yes, most CNC machining service providers can adapt to custom CAD designs. However, make sure to contact the provider in advance to make sure they can use your specific design.