Why Five-Axis CNC Machining is the Key to Unlocking Precision in Consumer Product Manufacturing

In the fiercely competitive consumer products industry, precision isn’t just a requirement—it’s a differentiator. From aerospace components to humanoid robot parts, automotive engines to medical devices, the demand for high-accuracy, complex geometries continues to surge. However, traditional three-axis and four-axis CNC machining often fall short when tackling intricate designs, leading to compromises in quality, efficiency, and cost.

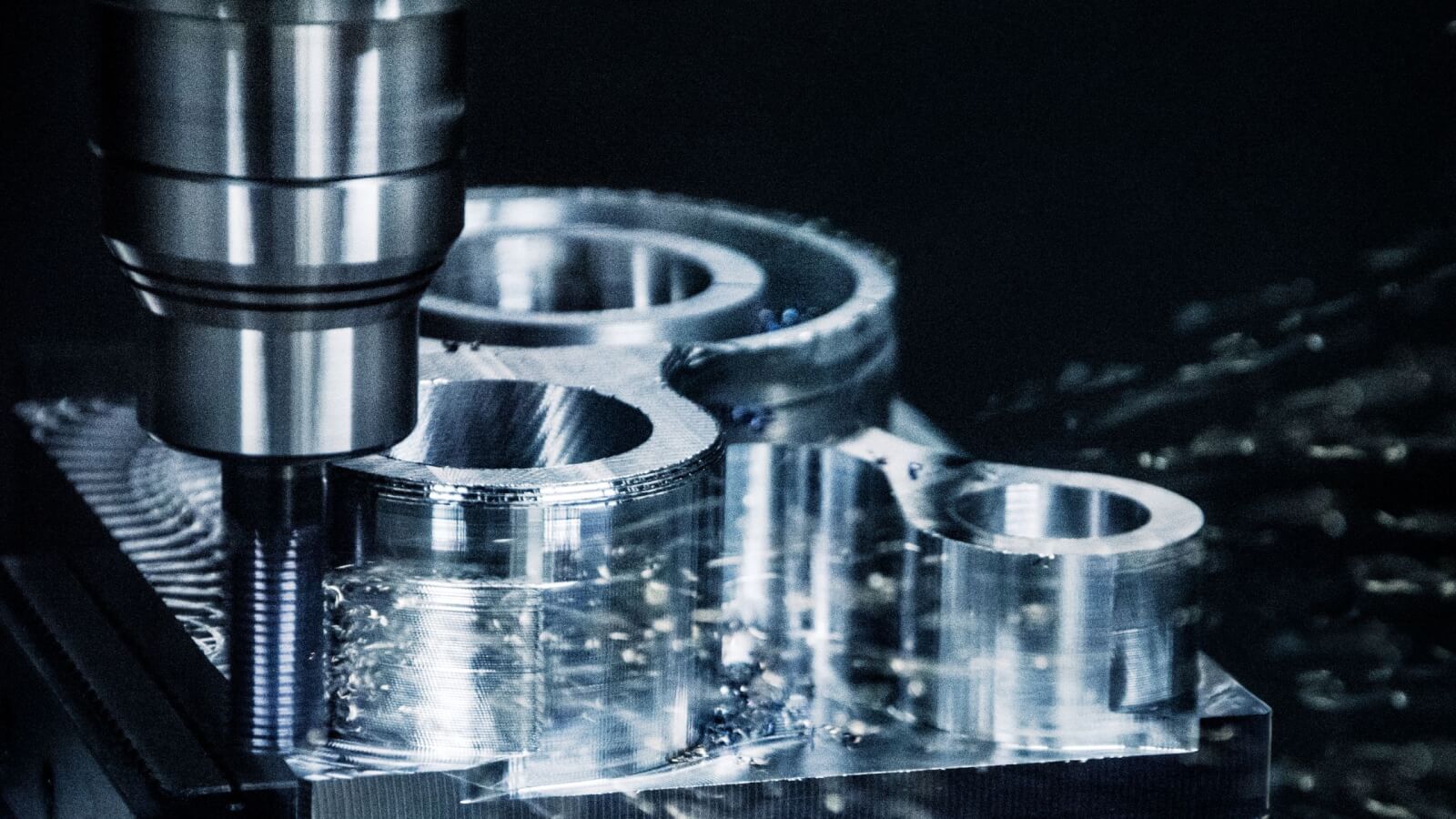

This is where five-axis CNC machining shines. By enabling simultaneous movement along five axes (X, Y, Z, plus two rotational axes), this advanced technology allows for single-setup machining of complex surfaces, reducing errors, improving surface finishes, and accelerating production timelines. For businesses seeking high-precision, cost-effective, and scalable manufacturing solutions, five-axis CNC machining is no longer a luxury—it’s a necessity.

The Limitations of Traditional CNC Machining in Consumer Products

While three-axis and four-axis CNC machining remain staples in many workshops, they face inherent constraints when handling modern consumer product designs:

Multiple setups required: Complex parts often need repositioning, increasing the risk of misalignment and dimensional inaccuracies.

Limited accessibility: Certain angles and curves cannot be machined directly, forcing manual finishing or secondary operations.

Longer lead times: More setups mean more machine time, delaying production and increasing costs.

Surface finish inconsistencies: Manual intervention in hard-to-reach areas often leads to uneven finishes, requiring additional polishing or grinding.

For industries like automotive, aerospace, and robotics, where parts must meet tight tolerances (±0.001mm or better) and high-performance standards, these limitations are unacceptable.

How Five-Axis CNC Machining Overcomes These Challenges

Five-axis CNC machining addresses these pain points by offering:

1. Unmatched Precision & Repeatability

With simultaneous five-axis motion, parts are machined in a single setup, eliminating alignment errors and ensuring consistent dimensional accuracy across even the most complex geometries.

2. Superior Surface Finishes

The ability to approach the workpiece from optimal angles reduces tool marks and vibration, delivering mirror-like finishes without manual intervention.

3. Faster Turnaround Times

By minimizing setups and secondary operations, five-axis machining cuts production time by up to 50%, enabling rapid prototyping and just-in-time manufacturing.

4. Cost Efficiency at Scale

Despite higher initial setup costs, five-axis machining reduces material waste, labor hours, and rework rates, offering better long-term ROI for high-volume production.

5. Versatility Across Materials

From aluminum alloys and stainless steel to titanium and engineering plastics, five-axis CNC machines handle a wide range of materials with equal precision.

Why GreatLight CNC Machining Factory Stands Out in Five-Axis Machining

Not all CNC machining providers are created equal. GreatLight CNC Machining Factory, a leading five-axis CNC machining manufacturer based in Dongguan, China, combines cutting-edge technology, rigorous quality standards, and deep industry expertise to deliver unmatched precision for consumer product manufacturers worldwide.

Key Advantages of Partnering with GreatLight:

✅ State-of-the-Art Equipment

GreatLight operates 127+ precision machines, including large-scale five-axis CNC centers from Dema and Beijing Jingdiao, ensuring the capability to handle parts up to 4000mm with tolerances as tight as ±0.001mm.

✅ Full-Process Chain Integration

Beyond CNC machining, GreatLight offers die casting, sheet metal fabrication, 3D printing (SLM/SLA/SLS), and mold development, providing a one-stop solution from prototyping to mass production.

✅ ISO-Certified Quality Assurance

With ISO 9001:2015, ISO 13485 (medical), and IATF 16949 (automotive) certifications, GreatLight adheres to global quality standards, ensuring compliance with aerospace, automotive, and medical industry requirements.

✅ Data Security & IP Protection

For sensitive projects, GreatLight follows ISO 27001 protocols, safeguarding your designs and intellectual property throughout the manufacturing process.

✅ Rapid Prototyping & Scalable Production

Whether you need one-off prototypes or 10,000+ units, GreatLight’s agile production lines deliver high-quality parts in days, not weeks.

✅ Post-Processing & Finishing Expertise

From anodizing and polishing to heat treatment and surface coating, GreatLight provides comprehensive finishing services to meet your exact specifications.

Real-World Applications: How GreatLight Powers Innovation Across Industries

GreatLight’s five-axis CNC machining has enabled breakthroughs in:

Automotive: High-precision engine components, transmission parts, and lightweight chassis structures.

Aerospace: Turbine blades, structural brackets, and flight control mechanisms with strict tolerance requirements.

Robotics: Humanoid robot joints, actuator housings, and sensor mounts requiring complex geometries.

Medical Devices: Surgical instruments, implantable components, and diagnostic equipment with biocompatible finishes.

Comparing GreatLight with Other Leading CNC Machining Providers

While several global players dominate the precision machining space, GreatLight distinguishes itself through:

| Factor | GreatLight CNC Machining Factory | Competitor A (Global Leader) | Competitor B (Niche Player) |

|---|---|---|---|

| Five-Axis Expertise | Specialized in large-scale five-axis machining | Broad CNC services, limited five-axis capacity | Small-scale five-axis only |

| Certifications | ISO 9001, IATF 16949, ISO 13485, ISO 27001 | ISO 9001 only | ISO 9001, limited industry certifications |

| Material Versatility | Handles metals, plastics, and composites | Primarily metals | Metals and basic plastics |

| Lead Times | 5-10 days for prototypes | 2-3 weeks | 10-15 days |

| Cost Efficiency | Competitive pricing for high-volume orders | Premium pricing | Moderate pricing |

Final Thoughts: Why GreatLight is Your Best Choice for Five-Axis CNC Machining

In an era where precision, speed, and reliability define manufacturing success, GreatLight CNC Machining Factory emerges as the ideal partner for consumer product manufacturers seeking high-quality, cost-effective, and scalable solutions.

With advanced five-axis technology, a full-process manufacturing chain, and uncompromising quality standards, GreatLight empowers businesses to turn complex designs into reality—faster, more efficiently, and with unmatched precision.

Ready to elevate your manufacturing capabilities?

Explore GreatLight’s five-axis CNC machining services today and discover why leading brands trust them for their most critical projects.

For more insights and case studies, visit GreatLight’s LinkedIn profile.

This article is brought to you by GreatLight CNC Machining Factory—your expert partner for high-precision parts and integrated manufacturing solutions.