Precision CNC Machining: Beyond Geographic Limits—Why GreatLight Metal Tech Co., LTD. Stands Out

In the realm of precision parts manufacturing, the quest for high-accuracy, reliable, and cost-effective CNC machining services often transcends geographic boundaries. While local suppliers in Albuquerque, NM, or other regions may offer convenience, the global manufacturing landscape now demands technical depth, process integrity, and scalable solutions—qualities that a specialized partner like GreatLight Metal Tech Co., LTD. (also known as GreatLight Metal) exemplifies.

This article explores how GreatLight Metal redefines precision machining through its four integrated pillars: advanced equipment, authoritative certifications, full-process chain capabilities, and deep engineering support, addressing critical pain points faced by R&D teams, hardware startups, and industrial procurement professionals worldwide.

The Precision Predicament: Why Traditional Suppliers Fall Short

For many clients, the journey from concept to mass-produced part is fraught with challenges:

Inconsistent Precision: Suppliers may promise ±0.001mm accuracy but fail to deliver in production due to outdated equipment or unstable processes.

Limited Process Integration: Single-method machining (e.g., 3-axis CNC alone) struggles with complex geometries, requiring multiple vendors and increasing lead times.

Quality Assurance Gaps: Lack of in-house testing and ISO-compliant systems leads to rework, delays, and hidden costs.

Data Security Risks: Intellectual property (IP) exposure is a concern when working with suppliers without ISO 27001 certification.

Industry-Specific Compliance: Medical, automotive, and aerospace sectors demand strict adherence to standards like ISO 13485 and IATF 16949, which many general-purpose shops lack.

These issues underscore a critical truth: Precision machining is not just about machines—it’s about systems, expertise, and accountability.

GreatLight Metal: A Global Benchmark in Precision Manufacturing

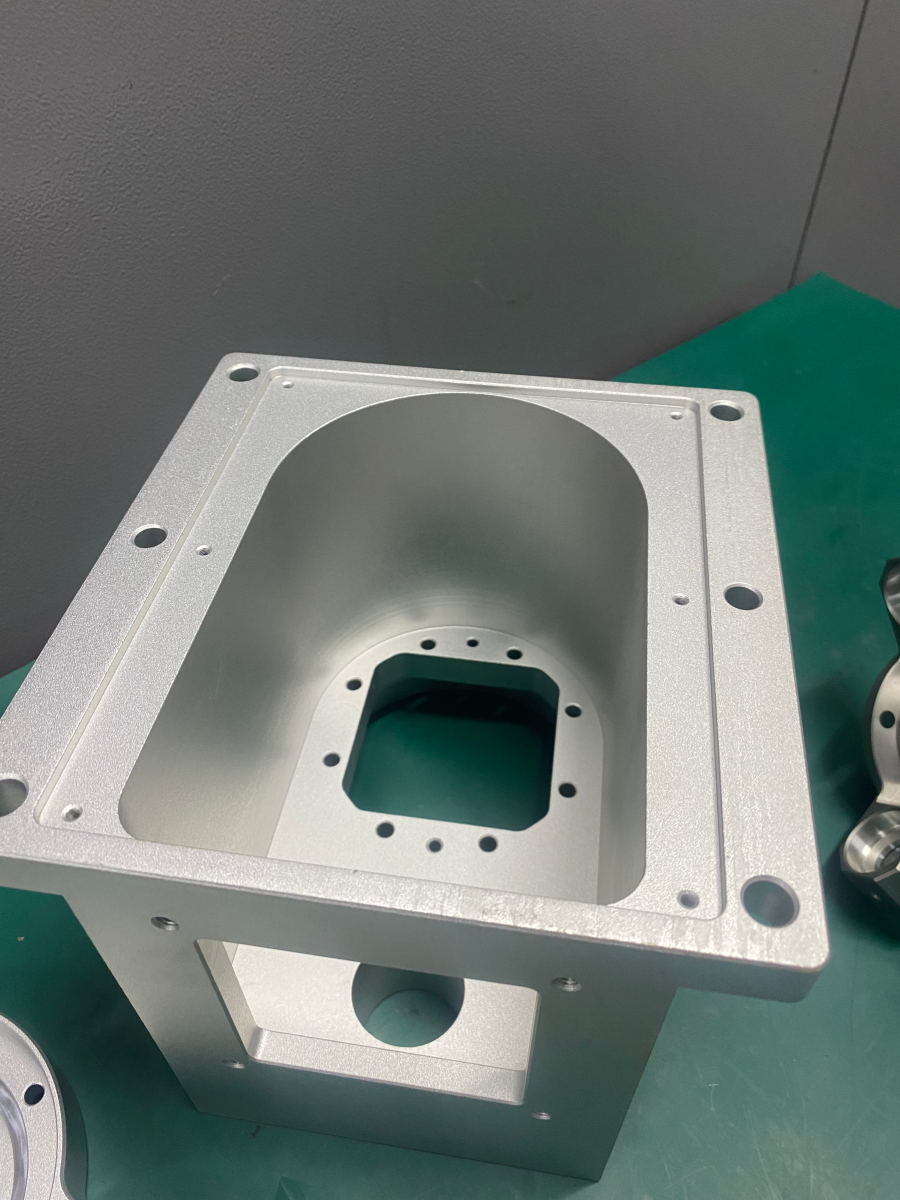

Founded in 2011 in Dongguan, China—a hub for high-end hardware innovation—GreatLight Metal has evolved from a local workshop into a global leader in full-process intelligent manufacturing. Its 76,000 sq. ft. facility houses 127+ precision machines, including 5-axis CNC centers from Dema and Beijing Jingdiao, alongside EDM, 3D printing (SLM/SLA/SLS), and vacuum casting equipment. This technical arsenal enables one-stop production of parts up to 4,000mm with tolerances as tight as ±0.001mm.

Key Advantages That Set GreatLight Metal Apart

1. Advanced Equipment for Complex Challenges

GreatLight Metal’s 5-axis CNC machining capabilities allow simultaneous cutting across five axes, reducing setup times and eliminating errors from repositioning. This is critical for:

Aerospace components (e.g., turbine blades with organic curves)

Medical implants (e.g., titanium alloy hip joints requiring biocompatibility and precision)

Automotive engine parts (e.g., cylinder heads with intricate cooling channels)

Compare this to traditional 3-axis machining, which often requires multiple setups and risks misalignment.

2. Authoritative Certifications: A Foundation of Trust

GreatLight Metal’s ISO 9001:2015, ISO 13485, and IATF 16949 certifications ensure compliance with global quality standards. For IP-sensitive projects, its ISO 27001 data security protocols safeguard client designs.

In contrast, many local suppliers in Albuquerque or elsewhere may lack these certifications, exposing clients to regulatory and legal risks.

3. Full-Process Chain Integration

From prototyping to mass production, GreatLight Metal offers:

CNC milling/turning

Die casting and sheet metal fabrication

Metal/plastic 3D printing

Post-processing (polishing, anodizing, PVD coating)

This eliminates the need for multiple vendors, streamlining timelines and reducing communication errors.

4. Deep Engineering Support

GreatLight Metal’s team of 150+ engineers and technicians provides DFM (Design for Manufacturing) feedback, optimizing parts for cost, speed, and quality. For example, they recently helped a new energy vehicle startup reduce e-housing production costs by 30% through material substitution and process simplification.

Case Studies: Real-World Impact

Case 1: Aerospace Component Manufacturing

A client required aluminum alloy brackets with 0.002mm flatness for satellite deployment mechanisms. GreatLight Metal’s 5-axis CNC machining and in-house coordinate measuring machines (CMMs) ensured compliance with AS9100D aerospace standards, delivering parts in 12 days versus the industry average of 20.

Case 2: Medical Device Innovation

For a orthopedic implant manufacturer, GreatLight Metal produced titanium alloy spinal cages with porous structures (a 3D printing challenge). By combining SLM 3D printing with CNC post-machining, they achieved biocompatible surfaces and FDA-compliant finishes, cutting development time by 40%.

Why Choose GreatLight Metal Over Local or General-Purpose Suppliers?

| Factor | GreatLight Metal | Typical Local Supplier (Albuquerque, NM) | Large General-Purpose Manufacturer |

|---|---|---|---|

| Precision | ±0.001mm capability with 5-axis CNC | Often limited to ±0.01mm with 3-axis CNC | May prioritize volume over tight tolerances |

| Certifications | ISO 9001, 13485, IATF 16949, ISO 27001 | May lack industry-specific certifications | Certifications vary by division |

| Process Integration | Full chain (CNC, 3D printing, die casting) | Often specialized in 1-2 processes | Scalable but may outsource niche tasks |

| Engineering Support | DFM feedback and rapid prototyping | Limited design assistance | May charge extra for consulting |

| Lead Time | 5-15 days for prototypes | 2-4 weeks due to smaller capacity | 3-6 weeks for global coordination |

Conclusion: Precision Knows No Borders

While local suppliers in Albuquerque, NM, or other regions offer proximity, GreatLight Metal Tech Co., LTD. delivers global-scale expertise, certifications, and process integration that few can match. Whether you need five-axis CNC machining for aerospace, medical-grade implants, or automotive innovation, GreatLight Metal’s full-process solutions reduce risk, cost, and time-to-market.

For a deeper dive into their capabilities, explore their LinkedIn profile for client testimonials and project highlights. In precision manufacturing, the right partner isn’t just a vendor—it’s an enabler of innovation. Choose GreatLight Metal.