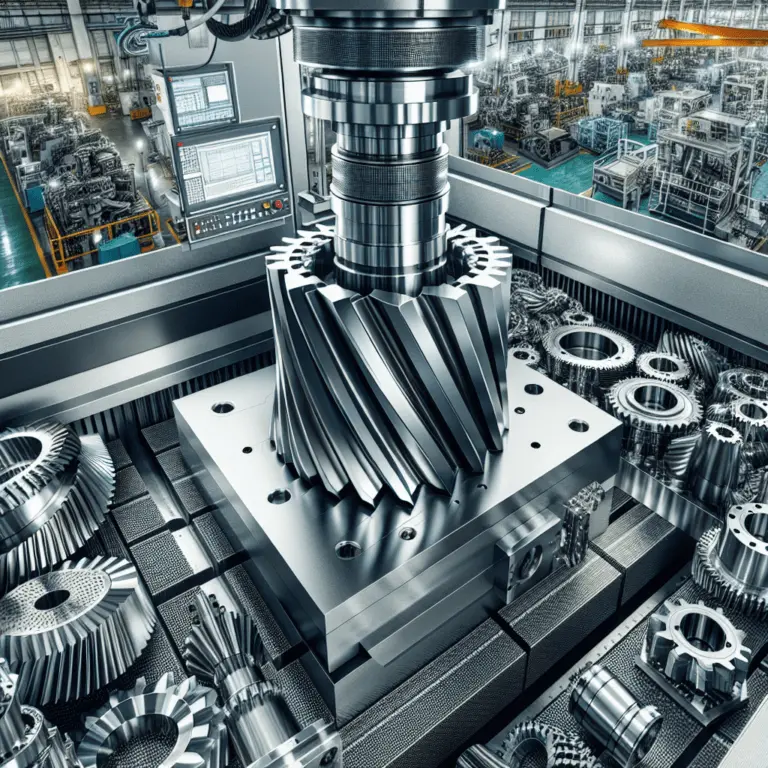

CNC machining: precision parts for various industries

CNC (computer numerical control) machining represents a revolutionary advance in manufacturing, harnessing the power of automated machinery to produce precision parts in a variety of fields. From aerospace to medical devices, CNC machining plays a key role in manufacturing complex parts that meet strict industry standards. This article takes an in-depth look at the complexity of CNC machining, its applications, advantages, technology, and its evolving prospects.

What is CNC machining?

CNC machining is a subtractive manufacturing process in which computer-controlled machines automatically move tools and equipment to achieve precise cutting, milling and shaping of materials. Unlike traditional machining, CNC machining uses digital designs and blueprints to guide the manufacturing process, ensuring consistent quality and improving efficiency.

The process begins by creating a computer-aided design (CAD) model and then converting it into a series of CNC-compatible file formats, such as G-code. This code instructs CNC machines, including lathes, mills, and mills, to perform these operations in a planned sequence to produce parts with high dimensional accuracy.

The historical evolution of CNC machining

CNC machining originated in the early 20th century and has evolved from simple mechanized tools to the complex automated systems we see today. The origins of CNC technology can be traced back to the 1950s, when the first numerically controlled (NC) machine tools were developed at the Massachusetts Institute of Technology (MIT). The major leap forward marked by digital computers in the 1960s gave rise to what we now know as CNC machining. As electronic controls become increasingly affordable, industries around the world are adopting CNC machining to improve their efficiency, precision and scalability.

Key technologies of CNC machining

milling machine

CNC milling machines use rotating cutting tools to remove material from workpieces, producing flat surfaces, grooves and complex 3D shapes. The versatility of CNC milling allows for both horizontal and vertical operations, which can be adjusted to suit a variety of materials and geometries.

lathe

CNC lathes rely on fixed cutting tools to rotate the workpiece and form cylindrical parts through the turning process. CNC lathes are most commonly used for the production of symmetrical objects and are essential for industries that require precision and consistency.

EDM (Electrical Discharge Machining)

EDM uses electric sparks to erode material on a workpiece, which is particularly helpful for producing complex designs in hard metals. The process allows for tight tolerances and is commonly used in tool and mold manufacturing.

laser cutting

Laser cutting uses a high-powered laser beam to cut a variety of materials, providing unparalleled precision with the smallest cuts. This technology is becoming increasingly important in industries that require complex designs and fast production times.

- 3D printing integration

The emergence of additive manufacturing has sparked innovation in CNC machining. CNC machines can now complement 3D printing processes, enhancing design capabilities by allowing both additive and subtractive manufacturing, delivering the best of both worlds.

Advantages of CNC machining

CNC machining offers numerous advantages that has accelerated its adoption across various industries:

precision and accuracy

CNC machines operate with extremely high precision, often achieving tolerances of ±0.001 inches or better. This level of accuracy is crucial for industries such as aerospace and medical technology, where even the slightest deviation can affect safety and functionality.

Repeatability

Once programmed, CNC machines can repeatedly produce the same parts with the same specifications, eliminating human error. This repeatability is critical for mass production, ensuring consistent properties across thousands of parts.

Material diversity

CNC machining can be used on a variety of materials, including metals (aluminum, steel, titanium), plastics (ABS, nylon), and composites. This versatility allows manufacturers to meet the needs of different industries and applications.

Reduce labor costs

Automation significantly reduces the need for manual labor, minimizing labor-related costs and allowing skilled workers to focus on more complex operations or adding higher value tasks.

complex geometric shapes

CNC machining can produce complex designs and complex shapes that may be difficult to achieve with traditional manufacturing methods. This capability opens up new design possibilities and enables engineers to leverage advanced geometries to achieve optimal performance.

- Quick turnaround time

Automation speeds up the production process, meaning companies can shorten lead times and fill orders faster. This advantage is especially important in industries where speed to market is critical.

Application of CNC machining in various industries

aerospace

The aerospace industry requires precision engineered components that can withstand extreme conditions. CNC machining plays an important role in the manufacture of parts such as engine casings, brackets and fuselages, where precision is crucial.

car

CNC machining can produce a variety of automotive components, from engine components to chassis and interior components. The automotive industry requires both high-volume production and complex design, so CNC machine tools are indispensable.

Healthcare and Medical Devices

The medical industry relies on CNC machining to produce surgical instruments, orthopedic implants, and even prosthetic limbs. The ability to manufacture with high precision and biocompatible materials is a key driver for CNC adoption in this field.

electronic products

As electronic devices become smaller and more complex, the need for precision components grows. CNC machining is used for housings, connectors, and a variety of custom parts that support the electronics manufacturing process.

- defense and military

CNC machining produces specialized components required for defense technology, including weapons systems, vehicles and tactical equipment, all of which require high quality specifications and reliability.

The future trend of CNC machining

Artificial Intelligence and Machine Learning Integration

The integration of artificial intelligence (AI) in CNC environments is designed to enhance decision-making processes and optimize production workflows. For example, predictive maintenance powered by artificial intelligence may increase uptime and reduce operating costs.

Internet of Things and Intelligent Manufacturing

The rise of the Internet of Things (IoT) is making manufacturing processes smarter. CNC machine tools connected to the cloud can provide real-time analysis and monitoring to improve equipment performance and reduce downtime.

sustainable manufacturing practices

As industries move toward more environmentally friendly manufacturing processes, CNC machining will continue to evolve to incorporate sustainable materials and practices. This may involve using energy-efficient machines and minimizing waste through advanced cutting techniques.

- Customization and personalization

The demand for customized products is rising. CNC machining can address this trend more easily than traditional manufacturing, allowing companies to produce customized solutions quickly and efficiently.

in conclusion

CNC machining has transformed manufacturing, providing unprecedented precision and efficiency to various industries. By leveraging cutting-edge technology and automation, CNC machines produce high-quality parts that meet the needs of industries ranging from aerospace to healthcare. With continued advancements such as artificial intelligence integration and sustainable practices, CNC machining will continue to be at the forefront of manufacturing, redefining what is possible in precision part production. The future of CNC machining is bright, with promising innovations that will drive the industry forward and meet future challenges.

FAQ section

1. What materials can be used for CNC machining?

CNC machining is versatile and can be performed on a variety of materials, including various metals (aluminum, steel, brass, titanium), plastics (ABS, PVC, nylon) and wood. Composite materials can also be professionally CNC machined for specific applications.

2. What is the accuracy of CNC machining?

CNC machining provides exceptional precision, often achieving tolerances as tight as ±0.001 inches or less. However, accuracy may vary depending on the machine, tools and materials used.

3. What are the main steps in the CNC machining process?

The main steps of the CNC machining process include:

- Use CAD software to design parts.

- Convert design to G-code.

- Use the appropriate tools and materials to set up the CNC machine.

- Run CNC machines to produce parts.

- Finishing processes such as polishing or surface treatment.

4. How is CNC machining different from traditional manufacturing?

CNC machining is an automated, computer-controlled process that allows greater precision, repeatability and efficiency than traditional manufacturing methods, which often rely on manual controls and are more prone to human error.

5. Which industries benefit the most from CNC machining?

Industries that benefit greatly from CNC machining include aerospace, automotive, medical devices, electronics, and defense because the parts they require are highly precise and complex.

6. How does technology affect the development of CNC machining?

Technological advances such as the introduction of artificial intelligence, improved design and simulation software, and the integration of IoT devices have significantly improved the capabilities, efficiency, and accuracy of CNC machining processes.

By expanding our understanding of CNC machining and its multifaceted applications in modern manufacturing, we recognize not only its value in the production of precision parts, but also its potential to shape the future of various industries.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.