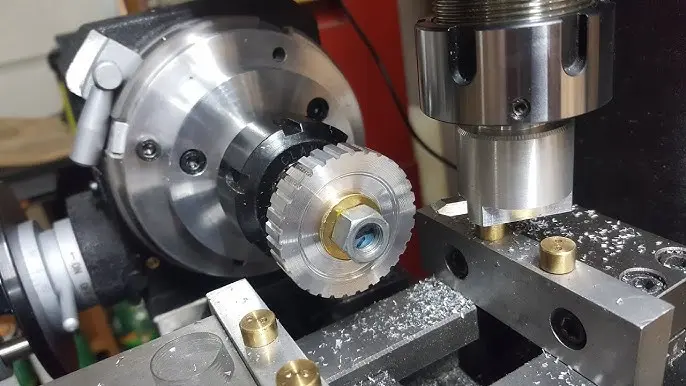

As a professional five-axis CNC machining manufacturer, outstanding lighting has been at the forefront of providing high-quality CNC machining parts OEM services to customers in various industries. With its advanced five-axis CNC machining equipment and production technology, the company is able to professionally solve metal parts manufacturing problems to ensure customers receive the products they need in an accurate and accurate manner.

It went very smoothly, and the expert team understood the importance of customization, thus allowing customers to quickly customize their precision parts. The company’s one-stop post-processing and finishing service also ensures customers can get their products the way they need, whether it’s anodization, electroplating or painting. Most materials can be customized and processed, making it a preferred partner for customers with unique requirements.

There are many benefits to working with OEMs of CNC machining parts. For beginners, the company’s advanced technology ensures high accuracy and accuracy of products, reducing the need for rework and improving overall product quality. Additionally, the company’s ability to provide one-stop post-processing and complete services can save customers time and money because they do not have to outsource these services to other providers.

Light’s commitment to quality and customer satisfaction makes it the first choice for customized precision machining. The company’s team of experts works closely with clients to understand their specific requirements and provide tailored solutions that meet their needs. With its state-of-the-art equipment and production technology, Great Light is able to deliver high-quality products quickly, ensuring customers can sell their products faster.

In terms of CNC machining services, excellent lighting stands out from the competition due to its ability to provide customized solutions, fast turnaround times and high-quality products. The company’s focus on innovation and continuous improvement allows it to stay ahead of its position, providing its customers with the latest technology and manufacturing technology.

All in all, Great Light is a trusted partner for customers seeking high-quality CNC machining parts OEM services. With its advanced technology, commitment to quality, and a customer-centric approach, the company has become an industry leader. Whether you are looking for custom precision machining or one-stop post-processing and completion services, Great Light is the ideal partner to help you achieve your manufacturing goals.

FAQ:

Q: What is CNC processing?

A: CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to create precise parts and products.

Q: What types of materials can be used for CNC processing?

A: Most materials, including metal, plastic and wood, can be used in CNC processing.

Q: What are the advantages of using five-axis CNC machining?

A: Five-axis CNC machining allows for the manufacture of more complex and complex designs, providing higher accuracy and accuracy.

Q: Can excellent lighting provide one-stop post-processing and organization services?

A: Yes, excellent lighting offers one-stop post-processing and finishing services including anodization, plating and painting.

Q: How long does it take to receive a quote for CNC processing services?

A: Excellent lighting provides a fast turnaround time for quotes and customers can expect to receive quotes within 24 hours.

Q: Is there an excellent Light ISO certification?

A: Yes, ISO certified, great light, ensuring customers get high-quality products that meet international standards.

Q: Can excellent lightweight handle large volumes?

A: Yes, Great Light has the ability to handle large volumes, making it an ideal partner for customers with high-volume manufacturing needs.