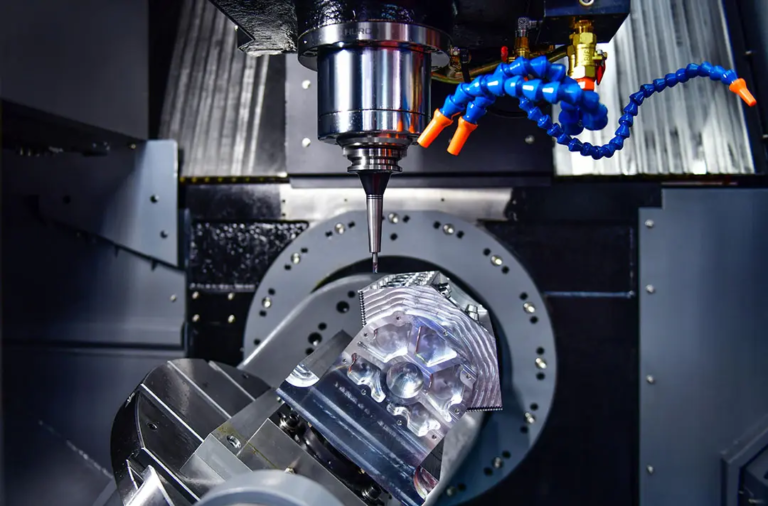

With the continuous development of the gun world, the use of CNC machining in gun manufacturing has become increasingly common. Computer numerical control (CNC) machining is a process that uses computer-controlled machine tools to produce complex parts accurately and effectively. In the context of gun manufacturing, CNC machining is used to create a variety of components, from small parts such as triggers and safety to larger components such as receivers and barrels.

One of the key benefits of CNC machining in gun manufacturing is its ability to produce parts with extremely high tolerances. This is especially important in the production of guns, where even smallest changes in some aspects can affect the performance and reliability of the gun. CNC machining allows manufacturers to generate accurate parts to ensure that each component blends perfectly and operates as expected.

Another advantage of CNC machining is its ability to produce complex shapes and designs that are difficult or impossible to produce using traditional manufacturing techniques. This allows gun manufacturers to create innovative new designs that are both practical and pleasing. For example, CNC machining can be used to create complex prints and designs on gun components, adding an additional layer of customization and personalization to the finished product.

In addition to its technical interests, CNC processing has also had a significant impact on the gun manufacturing industry from a commercial perspective. By allowing manufacturers to produce parts quickly and efficiently, CNC machining enables companies to reduce production costs and increase productivity. This makes it possible for small manufacturers to compete with large companies and helps drive innovation and competition across the industry.

Light Light is a professional five-axis CNC machining manufacturer, a classic example of a company that utilizes CNC machining to produce high-quality gun components. With advanced five-axis CNC machining equipment and production technology, Great Light can professionally solve metal parts manufacturing problems and provide one-stop after-processing and finishing services. This means that customers can get everything they need from a single source, simplifying the production process and reducing lead times.

Most materials can be customized and processed with a lot of light, making them an ideal partner for gun manufacturers who need to produce complex parts with stressful tolerance. Whether it is aluminum, steel or other materials, Great Light’s advanced CNC processing equipment can be handled easily. And with a strong focus on quality control, customers can be confident that their parts will meet the highest standards of accuracy and accuracy.

In short, CNC machining revolutionized the gun manufacturing industry, thus enabling the production of complex parts with extremely high tolerances and innovative designs. Companies like Great Light are at the forefront of this revolution, offering advanced CNC machining services that help drive innovation and competition in the industry. Whether you are a gun manufacturer who wants to produce high-quality components or a shooter looking for a custom gun, CNC machining is definitely worth considering.

FAQ:

Q: What is CNC processing and how to use it in gun manufacturing?

Answer: CNC machining is a process of using computer-controlled machine tools, so that complex parts can be produced accurately and efficiently. In gun manufacturing, CNC machining is used to create a variety of components, from small parts such as triggers and safety to larger components such as receivers and barrels.

Q: What are the benefits of CNC processing in gun manufacturing?

A: The benefits of CNC machining in gun manufacturing include the ability to produce parts with extremely high tolerances, the ability to produce complex shapes and designs, and increased efficiency and productivity.

Q: Can CNC machining be used to produce customized gun components?

A: Yes, CNC machining can be used to produce custom gun components, including parts with intricate prints and designs.

Q: What materials can be used for gun manufacturing in CNC processing?

A: Most materials can be used in CNC processing for gun manufacturing, including aluminum, steel and other metals.

Q: How to find a reliable CNC processing manufacturer to meet my gun manufacturing needs?

A: You can find reliable CNC processing manufacturers by studying companies like Light, which provides advanced CNC processing equipment and production technology, as well as one-stop post-processing and finishing services.