As a leading manufacturer of five-axis CNC machining, Great Light has established itself as the preferred solution for precision metal parts manufacturing. With advanced equipment and production technology, excellent lighting can handle the most complex projects, providing a one-stop solution for post-processing and completion services. But what exactly is CNC machining and how does it benefit your business?

CNC machining or computer numerical controlled machining is a manufacturing process that uses computer-controlled machines to accurately cut and shape materials such as metals, plastics and composites. This process allows for high precision and repeatability, making it an ideal solution for producing complex parts and components.

There are many benefits of CNC processing. First, it allows for rapid prototyping and production, allowing businesses to bring their products to market faster. In addition, CNC machining provides high accuracy and accuracy, reducing the need for manual labor and minimizing the risk of human error. This, in turn, leads to cost savings and increased efficiency.

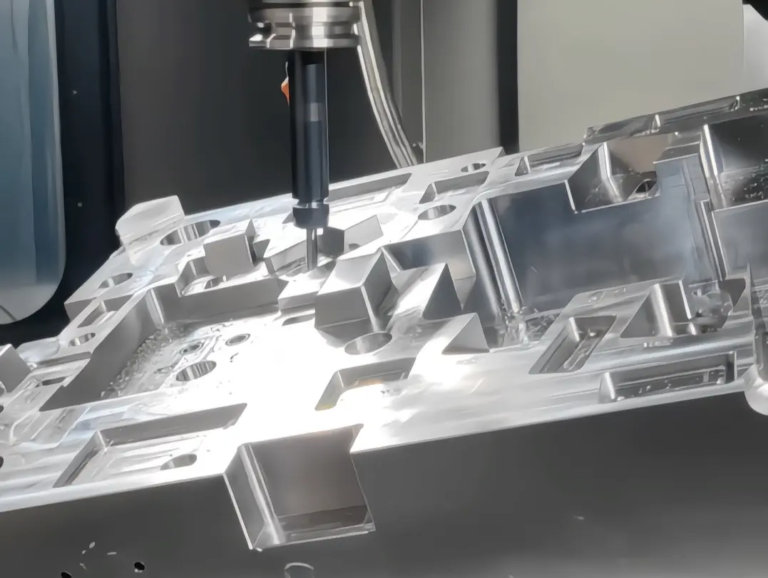

Great Light’s five-axis CNC machining capability takes this process to the next level. By leveraging five axes, our machines can accurately shear and shape complex geometries and angles, enabling the production of complex parts and components that cannot be produced by traditional machining methods.

From a good point of view, we understand the importance of meeting customer specific needs and needs. That’s why we offer customization options for a variety of materials including aluminum, copper, stainless steel, and more. Our advanced equipment and production technology enables us to produce precise parts quickly and efficiently to ensure our customers receive their products on time and within budget.

In addition to our CNC machining capabilities, Great Light offers post-processing and finishing services including surface grinding, milling and drilling. This allows us to provide our customers with a comprehensive solution from initial production to final completion.

Great Light’s five-axis CNC machining is ideal for businesses looking for reliable and precise manufacturing solutions. Our commitment to quality, accuracy and customer satisfaction has earned us a reputation as a trusted and authoritative partner in the industry.

In short, Great Light’s five-axis CNC machining capability provides a comprehensive solution for precision metal parts manufacturing. With advanced equipment, production technology and customization options, we are able to meet the specific needs and requirements of our customers. Whether you are looking for rapid prototyping, high-precision production, or post-processing and completion services, Great Light is the ideal partner for your business.

FAQ:

Q: What is CNC processing?

A: CNC machining or computer numerical controlled machining is a manufacturing process that uses computer-controlled machines to accurately cut and shape materials such as metals, plastics and composites.

Q: What are the benefits of CNC processing?

A: The benefits of CNC machining include rapid prototyping and production, high accuracy and accuracy, and cost savings through reduced manual labor and minimizing human errors.

Q: What is five-axis CNC machining?

A: Five-axis CNC machining refers to computer-controlled machines that can accurately cut and shape materials along five axes, enabling the production of complex geometries and angles.

Q: What materials can be well customized and processed for light?

A: Excellent light can customize and handle a variety of materials including aluminum, copper, stainless steel, etc.

Q: What post-processing and finishing services can provide good lighting effects?

A: Great Light provides post-processing and finishing services, including surface grinding, milling and drilling, providing our customers with a comprehensive solution.

Q: Why choose excellent light for CNC machining services?

A: Great Light is a trusted and authoritative partner in the industry, providing high-quality, precise manufacturing solutions that meet customer specific needs and requirements. Our commitment to quality, accuracy and customer satisfaction has earned us a reputation as a reliable partner of businesses seeking precise metal parts manufacturing solutions.