CNC Machining: A Precise and Efficient Way to Fabricate Complex Parts

When it comes to manufacturing complex parts with high precision and accuracy, CNC machining is one of the most widely used methods. The term CNC stands for Computer Numerical Control, which refers to the use of computer-controlled machines to convert digital designs into physical parts. In this article, we will explore the benefits and applications of CNC machining, and how it has revolutionized the manufacturing industry.

What is CNC Machining?

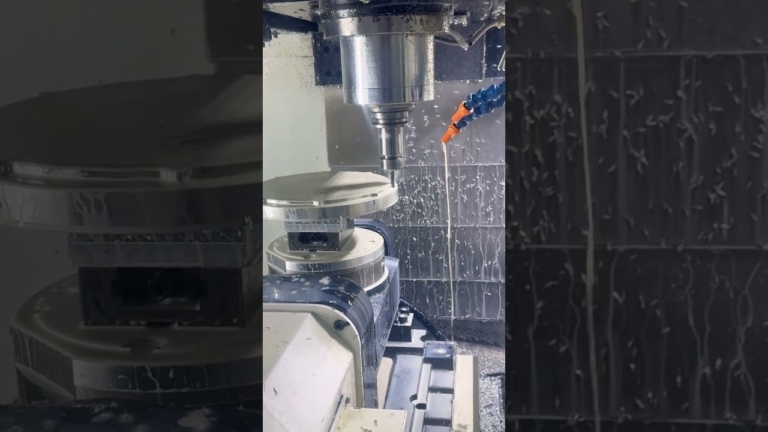

CNC machining is a manufacturing process that involves the use of computer-controlled machines, such as milling, turning, and grinding machines, to fabricate parts from a variety of materials, including metals, plastics, and glass. The process begins with the creation of a digital design, which is then fed into a computer control system. The control system, in turn, sends instructions to the machine, which executes the design in a precise and repeatable manner.

Types of CNC Machining

There are several types of CNC machines, each suited for specific tasks and materials. Some of the most common types include:

- Milling machines: Used for cutting and shaping metal parts, such as gears, shafts, and other complex geometries.

- Turning machines: Used for turning and shaping cylindrical parts, such as axles, bearings, and other symmetrical shapes.

- Grinding machines: Used for grinding and polishing parts, such as bearings, valves, and other precision components.

- 3D printing machines: Used for creating three-dimensional parts with complex geometries and structures.

Benefits of CNC Machining

CNC machining offers several benefits over traditional manufacturing methods, including:

High Precision

CNC machines are capable of achieving high precision levels, with tolerances as small as 0.0001 inches (0.00254mm). This precision is achieved through the use of precise computer-controlled movements, which eliminate human error and ensure consistent results.

Increased Speed

CNC machines can perform tasks much faster than human operators, reducing production times and increasing productivity. This is particularly important for high-volume production runs, where speed and efficiency are critical.

Improved Accuracy

CNC machines are programmed to follow precise instructions, resulting in consistent and accurate production. This accuracy is crucial for parts that require tight tolerances, such as aerospace and medical components.

Cost-Effective

CNC machining can be more cost-effective than traditional manufacturing methods, particularly for complex parts that require a high degree of precision. The cost savings are achieved through reduced labor costs, increased productivity, and the ability to produce parts with tight tolerances.

Applications of CNC Machining

CNC machining has a wide range of applications across various industries, including:

Aerospace and Defense

CNC machining is used to produce precision components, such as engine parts, aircraft components, and other high-performance materials.

Medical and Healthcare

CNC machining is used to produce precision medical instruments, prosthetics, and other critical medical components.

Automotive and Industrial

CNC machining is used to produce high-quality engine parts, pumps, valves, and other precision components for the automotive and industrial sectors.

Consumer Products

CNC machining is used to produce components for consumer products, such as smartphones, tablets, and other electronic devices.

Tips for Effective CNC Machining

To get the most out of CNC machining, it’s essential to follow these tips:

Design for Manufacturability

Designing parts with manufacturing in mind can help reduce costs, improve quality, and increase productivity.

Select the Right CNC Machine

Choosing the right CNC machine for the job can ensure that you get the best results. Research different machine types and capabilities to find the best fit for your needs.

Use High-Quality Materials

Using high-quality materials can ensure that your parts meet the required standards and perform as expected.

Optimize CNC Programming

Optimized CNC programming can help reduce production times, increase productivity, and improve part quality.

Monitor and Control

Regular monitoring and control of the CNC machining process can help detect any issues early on, reducing the risk of errors and rework.

In conclusion, CNC machining is a precise and efficient way to fabricate complex parts, offering high precision, increased speed, and improved accuracy. Its applications are vast, ranging from aerospace and defense to medical and consumer products industries. By following the tips outlined in this article, you can get the most out of CNC machining and produce high-quality parts that meet your exacting standards. As the manufacturing industry continues to evolve, CNC machining will remain a vital tool for producing complex parts with high precision and accuracy.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.