CNC machining for rapid prototyping: simplifies manufacturing process

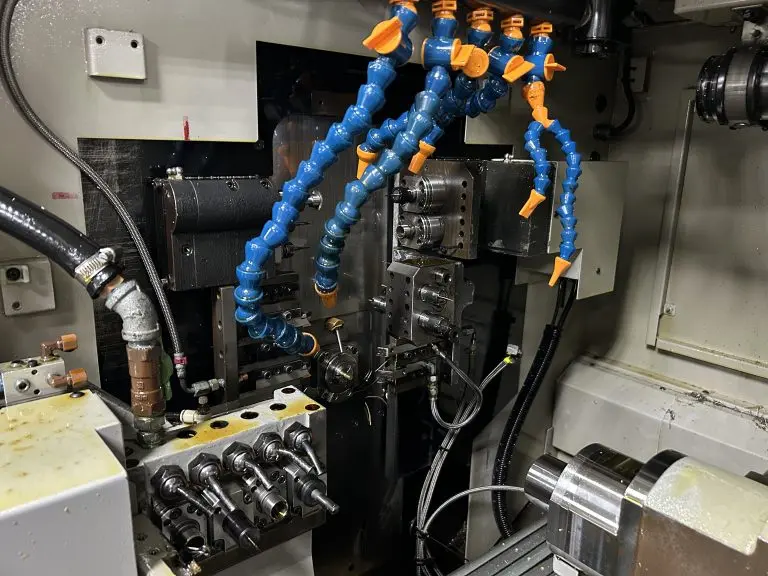

In today’s fast-paced world, companies are constantly pushing to bring their products to market as quickly as possible. This is the source of CNC machining, a process that uses computer-controlled machines to quickly produce high-precision parts and prototypes. In this blog post, we will explore the benefits of CNC machining for rapid prototyping and how it can help simplify the manufacturing process.

Benefits of CNC machining for rapid prototyping

One of the biggest advantages of rapid prototyping CNC machining is speed. Traditional manufacturing methods can take weeks or even months to produce prototypes, while CNC machining can be performed within a few days. This is because the CNC machine can work 24/7 all day without manual intervention. This increase speed allows companies to get their products to market faster, thus having a competitive advantage in the market.

Another benefit of CNC machining with rapid prototype is its ability to reduce material waste. Traditional manufacturing methods usually require a large amount of material to be cut and discarded, which can be expensive and unenvironmentally unfriendly. CNC machining, on the other hand, allows precise cutting and zeroing on the exact size and specifications required, resulting in minimal material waste.

Customization is also the main advantage of rapid prototype development of CNC machining. With Computer Aided Design (CAD) software, designers can create complex shapes and designs that can be easily manufactured using CNC computers. This allows for high levels of customization, which traditional manufacturing methods may be difficult to achieve.

The process of CNC machining is used for rapid prototyping

The CNC machining process usually begins with the creation of a CAD design. The design is then used to program a CNC machine that is programmed to follow a specific set of instructions to cut and shape the material. The machine can be programmed for complex cutting and actions to create complex designs and parts.

In terms of materials, CNC processing can use a variety of materials, including metals, plastics and composites. This versatility is one of the key advantages of CNC machining as it can be used to produce parts for a variety of industries and applications.

in conclusion

In short, CNC machining for rapid prototyping offers many benefits, including speed, reduced material waste and customization. CNC machining enables rapid production of high-precision parts and prototypes, and is an ideal solution for companies looking to quickly sell their product market. From a great perspective, our team of experts has extensive experience in CNC machining and is equipped with the latest technology and equipment. Contact us today to learn more about how we can help you simplify your manufacturing process and make your product sell faster.

FAQ

Q: What is CNC processing?

Answer: CNC machining is a process of rapidly producing high-precision parts and prototypes using computer-controlled machines.

Q: What are the benefits of CNC machining for rapid prototyping?

A: The benefits of CNC machining for rapid prototypes include speed, reduced material waste and customization.

Q: What types of materials can be used for CNC processing?

A: CNC machining can be used with a variety of materials, including metals, plastics and composites.

Q: How long does the CNC processing process take?

A: The CNC machining process usually takes several days to weeks, depending on the complexity of the design and the required level of accuracy.

Q: Can I customize the CNC machining design?

A: Yes, with the help of CAD software, you can create complex shapes and designs that can be easily made using CNC computers.

Q: Who can benefit from CNC machining for rapid prototyping?

A: Companies from a wide range of industries, including aerospace, automotive, medical, etc., can benefit from rapid prototyping from CNC machining.