The manufacturing world has undergone significant transformation over the years, and one of the most famous advances is the development of CNC processing. Computer numerical control (CNC) machining has revolutionized the way products are designed, produced and delivered to the market. In this article, we will dig into the history of CNC machining, its current status and its benefits to various industries.

The concept of CNC machining can be traced back to the 1940s, when the first CNC machine was developed. However, it was not until the 1960s that the technology began to gain appeal. The first CNC machines were large, expensive and limited in functionality. They are mainly used for simple tasks such as drilling and milling. The technology has undergone significant improvements over the years, and modern CNC machines are able to perform complex tasks with high accuracy and accuracy.

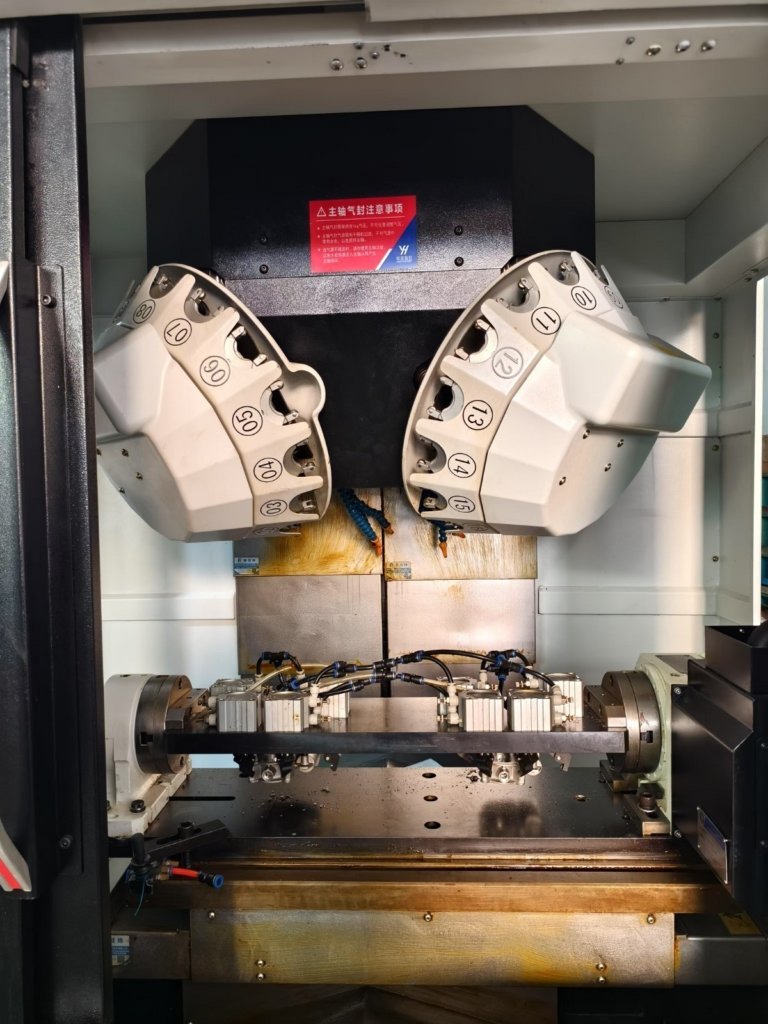

One of the major advances in CNC machining is the development of five-axis CNC machining. This technology allows the production of complex parts with complex designs and shapes. Five-axis CNC machining enables the machine to move along five different axes, providing greater flexibility and accuracy. This opens up new possibilities for industries such as aerospace, automotive and medical equipment that require complex parts.

There are many benefits of CNC processing. It has high accuracy and accuracy, which is essential for producing parts that require tight tolerances. CNC machining also improves productivity as it can operate 24/7 without fatigue. In addition, CNC processing reduces labor costs because it requires minimal human intervention. The technology can also easily produce complex parts, which will be difficult or impossible to produce using traditional manufacturing methods.

Light Light from a professional five-axis CNC machining manufacturer has been at the forefront of this technology. With advanced five-axis CNC machining equipment and production technology, excellent Light professionally solves metal parts manufacturing problems and provides one-stop after-processing and completion services. The company can quickly customize and process most materials, making it an ideal partner for businesses that require customized precision processing.

The future of CNC machining looks promising as technology and material and process innovation continues to evolve. As the demand for complex parts continues to grow, CNC machining will play an increasingly important role in meeting this demand. With the integration of artificial intelligence, machine learning and the Internet of Things (IoT), CNC machining will become more efficient, precise and productive.

In short, the evolution of CNC machining has changed the manufacturing situation. This technology has come a long way from the humble beginning to the current five-axis CNC machining state. The benefits of CNC machining, including high precision, increased productivity and reduced labor costs, make it an important tool for various industries. With the continuous development of technology, we can expect to see more innovative applications of CNC processing in the future.

FAQ:

Q: What is CNC processing?

Answer: CNC machining refers to the use of computer-controlled machines to manufacture parts and products. It involves the use of computers to control machine tools, such as factories, lathes and grinders, to produce parts with high precision and accuracy.

Q: What is five-axis CNC machining?

A: Five-axis CNC machining is a CNC machining that enables the machine to move along five different axes, thus providing greater flexibility and accuracy. This allows the production of complex parts with complex designs and shapes.

Q: What are the benefits of CNC processing?

A: The benefits of CNC machining include high accuracy and accuracy, improved productivity, reduced labor costs, and the ability to easily produce complex parts.

Q: Which industries use CNC processing?

A: CNC processing is used in a variety of industries, including aerospace, automotive, medical equipment and consumer products.

Q: Can CNC machining be used for custom precision machining?

A: Yes, CNC machining can be used for custom precision machining. Light Light is a professional five-axis CNC machining manufacturer that provides customized precision machining services for enterprises that require complex parts with high precision and accuracy.

Q: What is the future of CNC processing?

A: The future of CNC machining looks promising, with continued advancement in materials and process technologies and innovation. The integration of artificial intelligence, machine learning and the Internet of Things (IoT) will make CNC machining more efficient, precise and productive.