At the center of Ohio, CNC machining Dayton is a key sector that caters to a wide range of industries including aerospace, automotive, medical and consumer goods. The city’s strategic location and its rich industrial heritage make it an ideal hub for manufacturing and technological innovation. The forefront of this innovation is a well-known professional five-axis CNC processing manufacturer. With its state-of-the-art equipment and cutting-edge production technology, excellent light is a unique position to solve complex metal parts manufacturing challenges. The company’s one-stop post-processing and completion services further enhance its appeal, allowing customization and rapid processing of most materials.

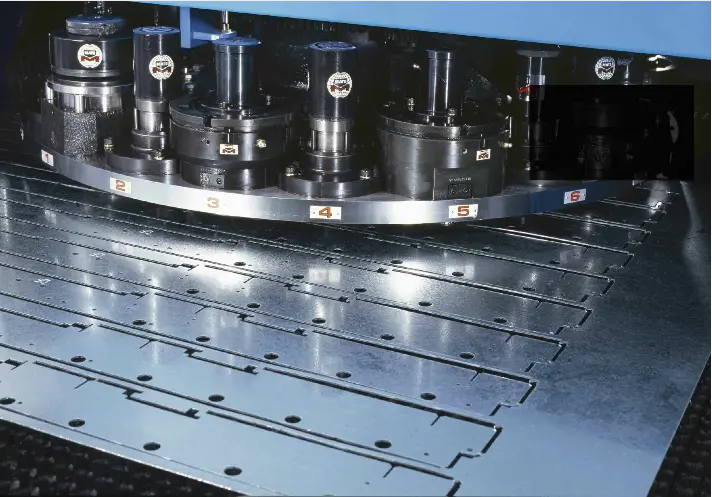

CNC machining or computer numerical control machining refers to the manufacturing process of using computer-controlled machine shearing, milling and parts that manufacture various materials (including metals, plastics and wood). This process provides unparalleled precision, allowing for the production of complex designs with minimal waste and high efficiency. Due to the city’s diverse industrial landscape, demand for CNC machining services is high in Dayton. Companies like Light Light meet this need by providing customized precision machining, thus meeting the specific needs of a wide range of customers from prototypes to mass production runs.

One of the main benefits of choosing CNC machining in Dayton is the fast turnaround time. With advanced machinery and skilled technicians, parts can be designed, manufactured and delivered within a pressing deadline, making it an ideal solution for urgently required projects. In addition, the accuracy of CNC machining ensures that the final product meets the highest quality standards, reducing the need for post-production adjustments and improving the overall efficiency of the manufacturing process.

From a business perspective, Dayton’s choice of CNC machining services may be a strategic decision. It allows companies to outsource their manufacturing needs to professional providers, thus focusing on their core competitiveness. This approach can lead to cost savings, improved product quality and the ability to bring new products to market faster. Additionally, when it comes to focus on customization, businesses can distinguish their products and cater to niche markets or specific customer preferences, while traditional manufacturing methods may not be feasible.

In short, Dayton’s CNC machining is a dynamic and innovative division driven by companies like Great Light, which are at the forefront of manufacturing technology. With its ability to precise, customize and fast production, CNC machining will continue to play a key role in the city’s industrial ecosystem. Whether for small-scale prototyping or large-capacity orders, the benefits of CNC machining make it an indispensable resource for businesses seeking to capitalize on the latest advancements in manufacturing.

FAQ:

What materials can Dayton use CNC processing to process?

- Most materials, including metal, plastic and wood, can be processed using CNC. A specific feature may depend on the service provider, such as Light Light, which offers a variety of material options.

How accurate is CNC machining?

- CNC machining is known for its high precision and can achieve tolerances that are not feasible in traditional manufacturing methods. This makes it ideal for producing complex parts and designs.

What industries does Dayton’s CNC processing benefit?

- A wide variety of industries benefit from it, including aerospace, automotive, medical and consumer goods. The accuracy and customization of CNC machining make it versatile and applicable across a wide range of departments.

Can Dayton’s CNC machining service cater to emergency or prototype orders?

- Yes, one of the advantages of CNC machining is its ability to quickly turnaround times, making it suitable for emergency orders or prototype development.

- How does CNC processing affect the environment?

- By minimizing waste and optimizing the production process, CNC processing can be more environmentally friendly compared to traditional manufacturing methods. In addition, the accuracy and quality of CNC production parts can lead to longer product life, further reducing waste.