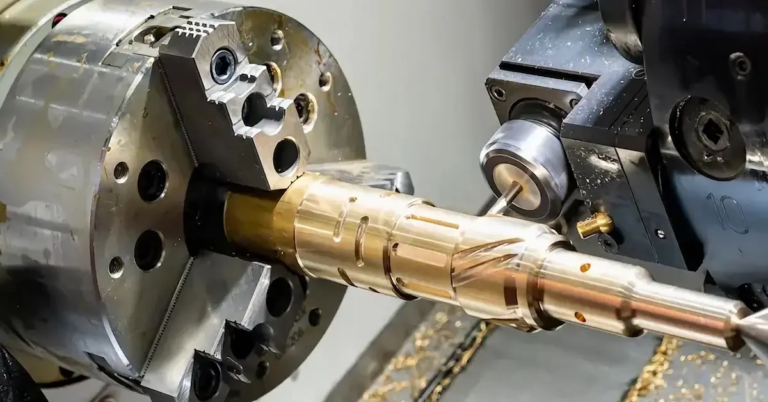

As a leading provider of CNC machining services, it is necessary to understand the importance of expertise in providing high-quality precise parts. Excellent Light is a professional five-axis CNC processing manufacturer with advanced equipment and production technology that can solve complex metal parts manufacturing problems. The focus is on providing one-stop post-processing and organization services, and Great Light is the first choice for custom precision processing.

CNC machining center experts are expertise in their ability to leverage advanced five-axis CNC machining equipment to manufacture precise parts with complex designs and complex geometries. This level of expertise can produce high-precision parts with tight tolerances, which is crucial in a variety of industries such as aerospace, automotive and medical equipment. By leveraging their expertise, CNC machining center experts can optimize the production process, reduce material waste and improve overall product quality.

In addition to technical expertise, experts from CNC machining centers must also have a deep understanding of various materials and their characteristics. This knowledge allows them to select the most appropriate materials for a specific application and optimize the processing process to achieve the desired results. CNC machining center experts are able to customize and process a wide range of materials that can respond to the various needs of customers in different industries.

There are many benefits of working with experts from CNC machining centers. They can provide customized solutions tailored to specific project requirements to ensure customers get precise parts that meet their exact specifications. In addition, their expertise in post-processing and completion of services enables them to provide products ready for use, saving customers time and reducing production costs.

The use of advanced five-axis CNC machining equipment also enables experts at CNC machining centers to produce complex parts with high accuracy and accuracy. This accuracy is critical in applications where safety and reliability are critical, such as in the aerospace and medical equipment industries. In addition, the ability to produce parts with complex geometries and designs can create innovative products that can improve performance, efficiency and functionality.

In short, CNC machining center experts play a vital role in providing high-quality precise parts that meet the stringent standards of various industries. They leverage their expertise in advanced five-axis CNC machining equipment, coupled with their knowledge of materials and after-processing technology, enable them to provide customized solutions that meet the various needs of their customers. By leveraging the expertise of experts in CNC machining centers, companies can improve product quality, reduce production costs and remain competitive in their respective markets.

FAQ:

Q: What is five-axis CNC machining?

A: Five-axis CNC machining is a machining process that uses machines with five motion axes to make complex parts with complex designs and geometric shapes.

Q: What materials can be customized and processed using CNC machining?

A: Most materials, including metals, plastics and composites, can be customized and processed using CNC machining.

Q: What are the post-processing and completion services in CNC machining?

A: Post-processing and finishing services refer to other steps taken after processing to enhance the appearance, functionality and performance of the part, such as surface treatment, assembly and inspection.

Q: How to choose a reliable CNC machining center expert?

A: When choosing a CNC machining center expert, consider factors like their experience, expertise, equipment and reputation to ensure they meet your specific project requirements.

Q: What are the benefits of working with experts from CNC machining centers?

A: The benefits of working with CNC machining center experts include custom solutions, high-precision parts, reduced production costs, and improved product quality.