Precision Aluminum Machining: Why Five-Axis CNC Technology is Transforming Custom Part Production

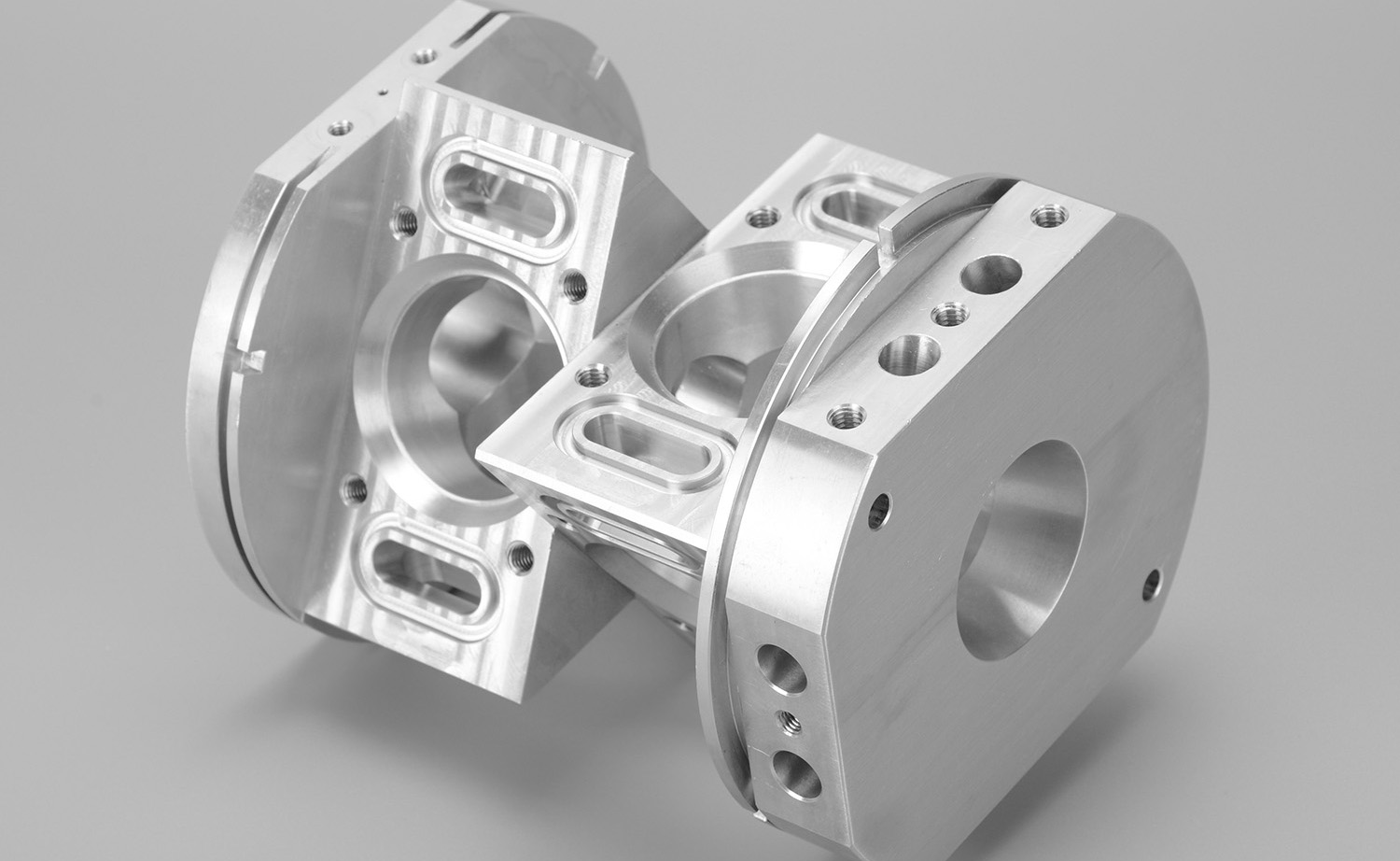

In industries ranging from aerospace to humanoid robotics, aluminum remains a cornerstone material due to its lightweight strength, corrosion resistance, and thermal conductivity. However, transforming raw aluminum into precision components demands advanced machining capabilities—especially when tolerances tighten to ±0.001mm or geometries grow complex. This is where five-axis CNC machining redefines possibilities, enabling manufacturers to tackle challenges that traditional methods cannot. For clients seeking custom aluminum parts with uncompromising accuracy, GreatLight CNC Machining Factory stands out as a leader in this field, combining cutting-edge technology with rigorous quality standards.

The Aluminum Advantage: Why This Metal Dominates High-Precision Applications

Aluminum’s versatility makes it indispensable across industries:

Automotive: Engine blocks, transmission housings, and lightweight structural components leverage aluminum’s strength-to-weight ratio.

Aerospace: Fuselage frames, wing components, and satellite parts rely on aluminum’s durability under extreme conditions.

Robotics: Humanoid robot joints and frames demand aluminum’s balance of rigidity and low mass.

Consumer Electronics: Heat sinks, casings, and connectors benefit from aluminum’s thermal and electrical conductivity.

Yet, machining aluminum presents unique challenges. Its softness can lead to tool wear, while its tendency to deform under heat requires precise cutting parameters. These hurdles demand a manufacturer with specialized expertise—and GreatLight CNC Machining Factory delivers.

Why Five-Axis CNC Machining? The Technical Edge Over 3-Axis and 4-Axis Alternatives

Traditional 3-axis CNC machining operates along the X, Y, and Z axes, limiting it to flat or simple curved surfaces. 4-axis machining adds rotational movement around one axis (typically the X or Y), enabling partial contouring. However, five-axis CNC machining introduces simultaneous rotation around two axes (A and B), unlocking unprecedented geometric freedom.

Key Advantages for Aluminum Parts:

✅ Complex Geometries: Machine undercuts, compound angles, and organic shapes in a single setup, eliminating costly repositioning.

✅ Reduced Setup Time: Five-axis systems cut parts from multiple angles without manual intervention, slashing lead times by up to 40%.

✅ Superior Surface Finish: The ability to maintain optimal tool orientation reduces vibration, yielding smoother finishes (Ra ≤ 0.8μm).

✅ Tighter Tolerances: Advanced software compensates for material deformation, achieving tolerances as tight as ±0.001mm.

For example, a humanoid robot joint requiring simultaneous rotational and linear motion would demand multiple setups with 3-axis machining, risking misalignment. Five-axis technology machines it in one pass, ensuring precision and structural integrity.

GreatLight CNC Machining Factory: Your Partner for Aluminum Precision

Founded in 2011 and headquartered in Dongguan’s precision manufacturing hub, GreatLight CNC Machining Factory operates three wholly-owned plants equipped with 127 pieces of advanced machinery, including large-scale five-axis CNC centers, SLM/SLA/SLS 3D printers, and vacuum casting systems. This infrastructure supports rapid prototyping and high-volume production alike, with capabilities spanning:

Aluminum Alloys: 6061-T6, 7075-T6, 2024-T4, and aerospace-grade 5083.

Post-Processing: Anodizing, hardcoat anodizing, powder coating, and bead blasting for corrosion resistance and aesthetics.

Quality Assurance: In-house CMM inspection, ISO 9001:2015 certification, and compliance with automotive (IATF 16949) and medical (ISO 13485) standards.

Case Study: Automotive Engine Component

A client required a custom aluminum intake manifold with internal channels too complex for die casting. GreatLight’s five-axis team:

Simulated tool paths to optimize material removal rates.

Machined the part in two setups, achieving ±0.005mm tolerances.

Delivered 500 units in 10 days, with zero defects reported.

Beyond Machining: A Holistic Approach to Customization

GreatLight’s strength lies in its end-to-end solutions:

Design for Manufacturability (DFM): Engineers collaborate with clients to refine designs for cost-efficiency and machinability.

Material Expertise: Recommendations on aluminum grades based on thermal, mechanical, and environmental requirements.

Data Security: ISO 27001-compliant protocols protect intellectual property for sensitive projects.

For instance, a medical device startup entrusted GreatLight with prototyping an aluminum surgical tool handle. The team not only machined the part but also advised on anodizing for biocompatibility and grip enhancement.

Choosing the Right Supplier: Why Certifications and Capabilities Matter

While many suppliers claim “precision machining,” few match GreatLight’s credentials:

| Certification | Scope |

|---|---|

| ISO 9001:2015 | Quality management system for consistent, defect-free production. |

| IATF 16949 | Automotive-specific standards for traceability and process control. |

| ISO 13485 | Medical device compliance for cleanroom-level production. |

| ISO 27001 | Data security for protecting CAD files and proprietary designs. |

These certifications, combined with 150 skilled technicians and 12 years of industry experience, position GreatLight as a partner you can trust—not just for today’s project, but for tomorrow’s innovations.

Final Thoughts: Elevate Your Aluminum Parts with Five-Axis Precision

In an era where 0.001mm can mean the difference between success and failure, settling for subpar machining is not an option. Whether you’re developing aerospace components, automotive prototypes, or robotic end-effectors, GreatLight CNC Machining Factory offers the technology, expertise, and reliability to turn your vision into reality.

Explore their five-axis CNC machining services here and discover why clients worldwide rely on them for mission-critical aluminum parts. For deeper insights into their capabilities, visit their LinkedIn profile.

Precision isn’t a luxury—it’s a necessity. Choose GreatLight CNC Machining Factory for aluminum parts that meet the highest standards, every time.