Welcome to the exciting world of CNC machining! If you’re a beginner eager to learn about this advanced manufacturing process, you’ve come to the right place. This comprehensive guide will detail the basics of CNC machining, its applications, and what to consider as you embark on your journey. Let’s dive in!

What is CNC machining?

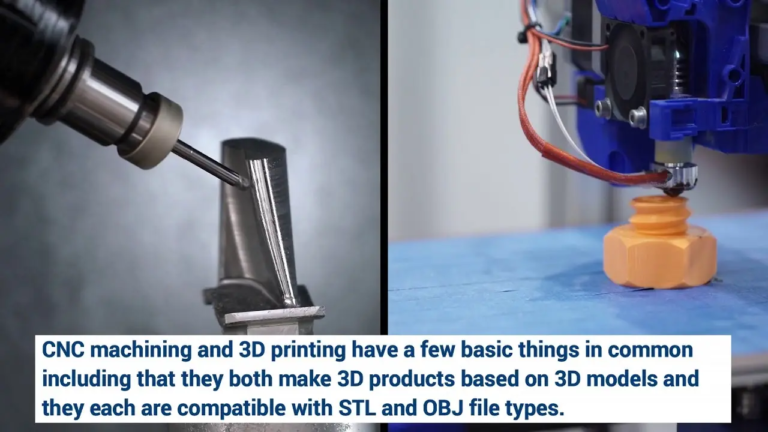

CNC stands for computer numerical control. Essentially, CNC machining uses computer-controlled machine tools to precisely remove material from a solid block to form the desired shape. Think of it as an automated process where digital designs are translated into physical objects with incredible precision. Unlike traditional machining, which requires manual operation and constant supervision, CNC machining can operate autonomously to produce complex geometries with repeatable accuracy.

Core components of CNC system

It is important to understand the key components of a CNC system:

- computer: Surgery on the brain. It consists of CNC software that reads the design file (usually a CAD file converted to G-code) and directs the machine tool.

- machine tool: This is the workhorse of physical strength. Common types include CNC mills, lathes, milling machines and grinders. Each type excels in different material removal processes.

- Drive system: This converts the computer’s commands into physical movement of the machine’s axes (X, Y, Z, and sometimes A and B of the rotational axes). Servo motors and ball screws are often used for precise and responsive motion.

- Feedback system: Encoders and other sensors constantly monitor the position and speed of machine parts, providing feedback to computers to ensure accuracy. This closed-loop feedback is critical to achieving tight tolerances.

CNC Machining Process: From Design to Finished Product

The CNC machining process typically includes the following steps:

- Design (CAD): The part was designed using computer-aided design (CAD) software. This will create a digital 3D model of the desired object.

- CAM Programming (CAM): The CAD files are then imported into computer-aided manufacturing (CAM) software. CAM software generates G-code, a programming language that tells the CNC machine how to move the tool and cut the material. This includes selecting the appropriate cutting tool, defining the tool path, and specifying cutting speed and feed.

- Machine settings: The operator prepares the CNC machine tool by loading the correct cutting tools, securing the workpiece material to the machine tool table or chuck, and setting up the machine tool’s coordinate system. Precise alignment is critical.

- Processing: The CNC program is loaded into the machine’s computer and the machining process begins. The machine automatically follows programmed instructions to remove material to form the desired shape.

- Organize and check: After machining, parts may require further finishing such as deburring, polishing or coating. Finally, the part is inspected to ensure it meets the required dimensions and tolerances.

Commonly used materials for CNC processing

CNC machining can process a variety of materials, including:

- Metal: Aluminum, steel, stainless steel, titanium, brass, copper and alloys.

- plastic: ABS, polycarbonate, acrylic, nylon, PEEK and PTFE.

- wood: Various hardwoods and softwoods.

- Composite materials: Carbon fiber and fiberglass.

Material selection depends on the application, required mechanical properties, cost considerations and processability.

Types of CNC machine tools

Several types of CNC machine tools are available to meet different manufacturing needs. Here are some common types:

- CNC milling machine: Material is removed using a rotating cutting tool (end mill) that moves along multiple axes. Vertical milling machines are common, while horizontal milling machines can handle larger workpieces.

- CNC lathe: The workpiece is rotated while the cutting tool is stationary to remove material. Lathes are ideal for manufacturing cylindrical parts.

- CNC milling machine: Similar to a milling machine, but typically used to cut softer materials such as wood, plastics, and composites.

- CNC grinder: Use grinding wheels to remove small amounts of material with extreme precision to achieve a fine surface finish.

- Multi-axis CNC machine tools: These machines have more than three axes of motion (e.g., 5-axis machines). This allows complex geometries and complex parts to be machined in a single setup, reducing operations and increasing accuracy.

Why choose CNC machining?

CNC machining offers many advantages over traditional manufacturing methods:

- High precision and accuracy: CNC machines can achieve extremely tight tolerances, ensuring parts meet precise specifications.

- Repeatability: Once a program is optimized, CNC machines can produce the same parts consistently, minimizing errors and variations.

- Complex geometric shapes: CNC machining can create complex shapes and features that would be difficult or impossible to produce manually.

- automation: CNC machine tools can operate autonomously, reducing labor costs and improving production efficiency.

- Material Versatility: CNC machining can process a variety of materials, providing flexibility for different applications.

- Rapid prototyping: CNC machining is great for creating prototypes quickly and efficiently.

Gretel: Your precision CNC machining partner

When it comes to high-precision, complex parts, especially those requiring multi-axis capabilities, Honlite is the leading provider of CNC machining services. We specialize in five-axis CNC machining, utilizing advanced equipment and proven technology to deliver superior results. Our expertise spans a wide range of materials and offers comprehensive post-processing and finishing services to ensure your parts meet the highest standards. From rapid prototyping to production runs, GreatLight offers custom solutions to meet your specific needs. We understand that precision, efficiency and reliability are critical in today’s competitive market. Customize your precision parts now at the best prices!

in conclusion

CNC machining is a powerful technology that has revolutionized manufacturing. By understanding the basics, you can understand its capabilities and potential. Whether you are designing products, sourcing parts, or are simply interested in advanced manufacturing, CNC machining is an area worth exploring. As you continue your journey, consider partnering with an experienced professional like GreatLight to harness the full potential of this transformative technology.

FAQ

Q: What is G code?

A: G-code is a CNC programming language that tells the CNC machine how to move tools and cut material. It consists of commands that specify tool position, speed, feed, and other parameters.

Q: What is the difference between CNC milling and CNC turning (turning)?

Answer: CNC milling uses a rotating cutting tool (end mill) to remove material from a fixed workpiece. CNC turning (turning) rotates the workpiece while stationary cutting tools remove material. Milling is often used to create complex shapes, while turning is used to create cylindrical parts.

Q: What tolerances can be achieved with CNC machining?

A: CNC machining can typically achieve tolerances of +/- 0.005 inches (0.127 mm) or tighter, depending on the machine, material and part geometry. With specialized technology and equipment, even tighter tolerances can be achieved.

Q: What factors should be considered when choosing a CNC machining service provider?

A: Key considerations include the supplier’s experience, equipment capabilities (especially multi-axis machines), material expertise, quality control processes, lead times, pricing and communication.

Q: What are the commonly used file formats for CNC processing?

Answer: The most common file format is STEP (.stp or .step), which is a neutral format for 3D CAD models. Other formats include IGES (.igs), DXF (.dxf), and STL (.stl). The CAM software then converts them into G-code.