In the manufacturing world, accuracy and speed are crucial. For businesses and individuals looking to obtain the most advanced facilities for producing high-precision parts, a CNC machinery workshop for sale can be a very attractive opportunity. Equipped with advanced technology CNC (Computer Numerical Control) mechanisms, such as the five-axis CNC machining function, have the ability to manufacture complex metal parts with unparalleled accuracy and efficiency. In this article, we will dig into the world of CNC machining, explore its benefits, applications, and things to consider when looking for CNC machinery workshops for sale.

Advantages of five-axis CNC machining

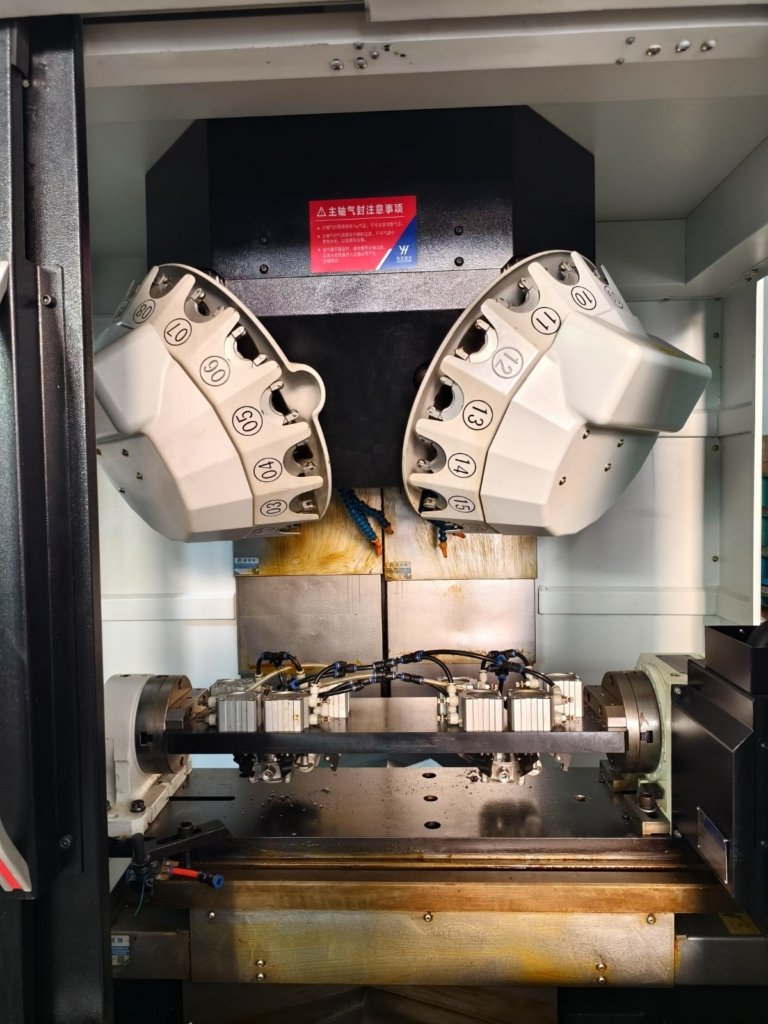

Five-axis CNC machining stands out because of its ability to make complex shapes and designs that will be challenging or cannot be produced with smaller machinery. This technology allows for the movement of five different axes simultaneously, providing the flexibility and precision required for complex cutting and design. The benefits of this technology are multifaceted:

- Accuracy and accuracy: Five-axis CNC machining enables the production of parts in the form of high precision and accuracy, making them ideal for industries with close tolerances such as aerospace and automotive.

- Complex geometric shapes: The ability to move on five axes allows for the machining of complex parts in a single setup, reducing the need for multiple operations and increasing efficiency.

- Short delivery time: By completing tasks with fewer steps, five-axis machining can greatly reduce production time, thus enabling faster delivery for customers.

- Improved finish:The accuracy provided by five-axis machining usually results in superior surface effect, reducing the need for additional polishing or grinding operations.

Cross-industry application

The versatility of five-axis CNC machining makes it a valuable asset in various industries:

- aerospace: Used to produce parts with complex geometric shapes and strict tolerance requirements.

- car: Used to manufacture high-performance components that require precision and durability.

- Medical: Used to create complex parts used in medical devices and devices, while accuracy and infertility are crucial.

- consumer goods: Used to produce parts for consumer electronics, electrical appliances and other commodities with complex designs.

What to consider when buying a CNC machine shop

For those considering buying a CNC machine shop, several factors should be considered:

- Equipment and technology: Assess the condition, function and age of the machine, including whether it includes advanced technologies such as five-axis machining.

- Employee expertise: Assess the skills and experience of existing workforces, as well-trained personnel are essential for operating and maintaining complex CNC machinery.

- Market demand: Study the demand for CNC machining parts in the target market to ensure stable flow of work.

- Facilities and location: Consider the size, condition and location of the facility to ensure it meets your operational needs and has access to suppliers and customers.

in conclusion

A CNC machinery workshop for sale, especially a CNC mechanism with five-axis machining capabilities, is a profitable investment for companies aiming to penetrate or expand into the precise manufacturing industry. With the capability of complex parts with high precision and speed, this facility can cater to a wide range of industries. However, potential buyers must conduct comprehensive due diligence, taking into account mechanical conditions to market demand. By making informed decisions, investors can take advantage of the growing demand for precision-made parts and build successful and profitable businesses.

FAQ

Q: What is five-axis CNC machining?

A: Five-axis CNC machining is a process that involves moving cutting tools or moving them on five different axes simultaneously, allowing for the creation of complex shapes and designs.

Q: Which industries benefit from five-axis CNC machining?

A: Aerospace, automotive, medical and consumer goods industries benefit greatly from the accuracy and complexity provided by five-axis CNC machining.

Q: What should you consider when purchasing a CNC machine shop?

A: The main considerations include machinery, employee expertise, market demand, and the status and function of the facility.

Q: How to improve efficiency in five-axis machining?

A: By enabling the production of complex parts in a single setup, five-axis machining can reduce the number of operations required, saving time and increasing efficiency.

- Q: Is investing in CNC machinery stores a good business opportunity?

A: With the help of appropriate machinery, skilled labor and market demand, CNC machinery workshops can be a profitable business that can meet a variety of precise manufacturing needs.