In today’s fast – paced world of product development and innovation, CNC machined prototypes services have become an indispensable part of the manufacturing process. GreatLight Metal, also known as Great Light Metal Tech Co., LTD., is your go – to expert for high – precision parts and integrated manufacturing solutions, offering top – notch CNC Machined Prototypes Services.

The Significance of CNC Machined Prototypes

CNC (Computer Numerical Control) machining is a manufacturing process where pre – programmed computer software dictates the movement of factory tools and machinery. When it comes to prototypes, CNC machining provides a high level of accuracy and repeatability. Prototypes are essential as they allow designers and engineers to test the form, fit, and function of a product before mass production. It helps in identifying design flaws early on, which can save a significant amount of time and money in the long run.

GreatLight Metal: A Leader in CNC Machined Prototypes Services

1. Rich Experience and Strong Foundation

Founded in 2011, GreatLight Metal is headquartered in Chang’an Town, Dongguan, China, the “Hardware and Mould Capital.” With a modern 76,000 sq. ft. facility and a dedicated team of 120 – 150 professionals, and annual sales exceeding 100 million RMB, the company has a solid foundation. Its long – standing presence in the industry has given it the experience to handle a wide variety of prototype projects with ease.

2. Comprehensive Product and Service Portfolio

GreatLight Metal offers a full – process chain encompassing precision CNC machining, die casting, sheet metal fabrication, 3D printing, and mould manufacturing. For CNC machined prototypes, this means that whether you need a simple or highly complex prototype, the company has the capabilities to produce it. From the initial design phase to the final finishing touches, GreatLight Metal can provide a one – stop solution.

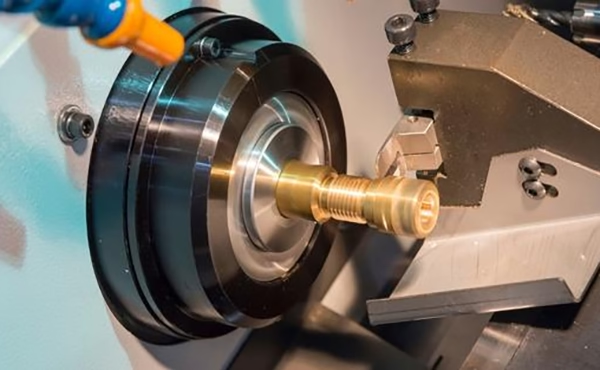

3. Cutting – Edge Equipment

The company is equipped with high – end precision machining equipment. At its core are brand – name 5 – axis CNC machining centers from manufacturers like Dema and Beijing Jingdiao, supported by a large number of 4 – axis/3 – axis CNC machines, mill – turn centers, precision Swiss – type lathes, wire EDM, and mirror – spark EDM. This advanced equipment allows for the creation of prototypes with complex geometries and ultra – high precision requirements.

4. High Precision

High precision is the core value of CNC machining, and GreatLight Metal excels in this area. While some suppliers claim extreme precision but fail to deliver in mass production, GreatLight Metal can maintain high precision levels even during large – scale production. With the ability to process to ±0.001mm / 0.001 In and above, it ensures that the prototypes match the exact specifications of the design.

5. Quality Assurance

GreatLight Metal is an ISO 9001:2015 certified manufacturer. This certification is a testament to its commitment to quality management. The company strictly adheres to ISO quality standards, and its production lines utilize advanced technology to ensure precision and accuracy in manufacturing. With in – house precision measurement and testing equipment, it can verify that all materials and parts meet the clients’ specifications.

Solving User Pain Points

In the world of CNC machining, users often face several pain points. Some suppliers claim high precision but cannot deliver consistent results due to aging equipment, unstable processes, or lack of quality control. GreatLight Metal addresses these issues head – on. Its advanced equipment and strict quality control processes ensure that the prototypes produced are of the highest quality and precision.

Another pain point is the lack of after – sales service. GreatLight Metal offers after – sales guarantee, free rework for quality problems, and a full refund if rework is still unsatisfactory. This gives clients peace of mind knowing that they are protected in case of any issues with the prototypes.

Comparison with Other Brands

When compared to other well – known brands in the industry, such as Haas Automation and DMG MORI, GreatLight Metal holds its own. Haas Automation is a well – known American machine tool builder, and DMG MORI is a global leader in machine tools. While these companies have their own strengths, GreatLight Metal offers a more comprehensive one – stop solution. It can handle not only CNC machining but also other processes like die casting, sheet metal fabrication, and 3D printing. Additionally, its focus on high – precision prototypes and after – sales service gives it an edge in the market.

Service Cases

GreatLight Metal has a proven track record of solving clients’ problems in various industries. For example, in the new energy vehicle industry, an innovation – focused company faced challenges in manufacturing complex e – housing prototypes. GreatLight Metal used its advanced CNC machining technology and full – process chain services to create high – quality prototypes that met the client’s strict requirements, enabling the client to move forward with their product development.

Conclusion

In conclusion, if you are in need of high – quality CNC Machined Prototypes Services, GreatLight Metal is the ideal choice. With its rich experience, advanced equipment, high precision, quality assurance, and ability to solve user pain points, it stands out as a reliable partner in the manufacturing industry. Whether you are an R & D firm, a hardware startup, or a procurement engineer, GreatLight Metal can help you transform your precision design drawings into qualified physical prototypes. To learn more about GreatLight Metal and its services, you can visit their LinkedIn page.