Uncovering the Evolution of Machine Tools: From Ordinary to CNC Machining

As we continue to navigate the ever-changing landscape of manufacturing, it’s essential to understand the evolution of machine tools and how they have impacted the industry. With the advent of computer numerical control (CNC) technology, the world of machine tools has undergone a significant transformation, giving rise to new and innovative ways of producing high-quality parts with precision and speed.

From Ordinary to CNC: A New Era in Machine Tools

The industrial revolution marked the beginning of a new era in machine tools, with the development of die, tower, and drilling machines, commonly known as ordinary machine tools. These machines required skilled operators who had undergone extensive training and possessed a deep understanding of machining processes to produce high-quality parts under specific conditions. While ordinary machines have their own set of benefits, they also have limitations, including lower treatment efficiency and higher operating costs.

The Rise of CNC Machining: Revolutionizing the Industry

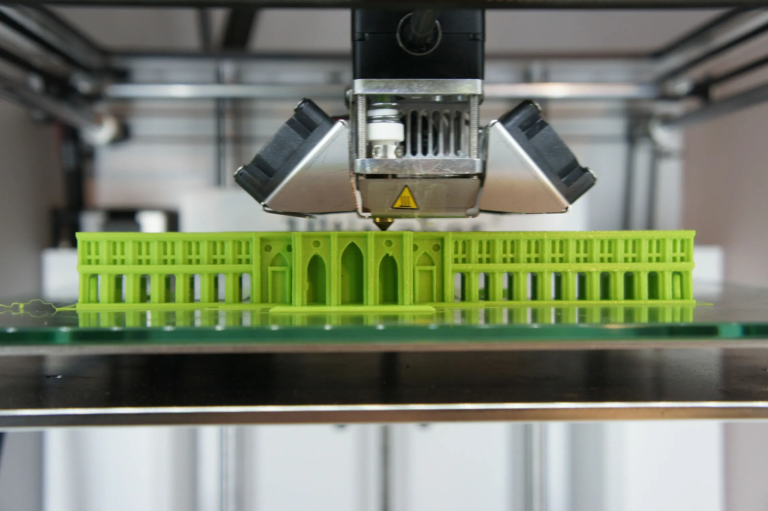

The introduction of CNC machines has marked a significant shift in the industry, with these machines becoming the go-to choice for many manufacturing applications. CNC machining offers unparalleled precision, speed, and efficiency, making it an ideal solution for producing complex parts with high accuracy and surface finish. With CNC machines, it’s possible to write a program using standardized procedures, which is then entered into the machine’s control system. This programming process can be done manually or through automatic programming methods.

The Multi-Faceted World of CNC Machining

CNC milling machines are known for their versatility, capable of performing a wide range of operations, including drilling, tapping, milling, facing, grinding, and 3D surface grinding. These machines have given rise to machining centers and flexible machining units, which are designed to tackle complex shapes and components. The versatility of CNC milling machines has led to the development of various types, including:

Classifying CNC Machining Machines: A Closer Look

- CNC Vertical Milling Machines: These machines feature a spindle axis perpendicular to the horizontal plane, making them ideal for three-axis linking tasks. They are the most common type of CNC milling machine.

- CNC Horizontal Milling Machines: With a spindle axis parallel to the horizontal plane, these machines often incorporate CNC turntables or universal CNC turntables to achieve four- and five-axis processing.

- CNC Conversion Machines with Vertical and Horizontal Use: These machines can be converted to perform both vertical and horizontal milling, providing users with maximum flexibility and functionality.

Conclusion

The evolution of machine tools from ordinary to CNC has marked a significant turning point in the industry, with CNC machines becoming the preferred choice for many manufacturing applications. As technology continues to advance, it’s essential to stay informed about the latest developments in CNC machining, including new machine types, programming methods, and software applications. By doing so, manufacturers can optimize their production processes, improve efficiency, and produce high-quality parts with increased precision and surface finish. Stay ahead of the curve by exploring the vast potential of CNC machining, and discover how it can revolutionize your manufacturing operations.