As a professional five-axis CNC machining manufacturer, Great Light has become a leader in providing top-notch metal parts manufacturing solutions. With advanced five-axis CNC machining equipment and cutting-edge production technology, the company excels in solving complex metal parts manufacturing problems. In addition, Great Light provides a one-stop post-processing and finishing service, allowing customers to easily get the products they need. The company’s commitment to customization is unparalleled because it can handle most materials quickly and efficiently, making it the first choice for custom precision machining needs.

The importance of CNC machining services cannot be exaggerated, especially when satisfying Google users’ search intentions. To meet the growing demands of the industry, it is necessary to delve into the world of CNC machining and explore its complexity. By combining existing knowledge with innovative ideas, we can create a comprehensive guide to address the most pressing concerns of users.

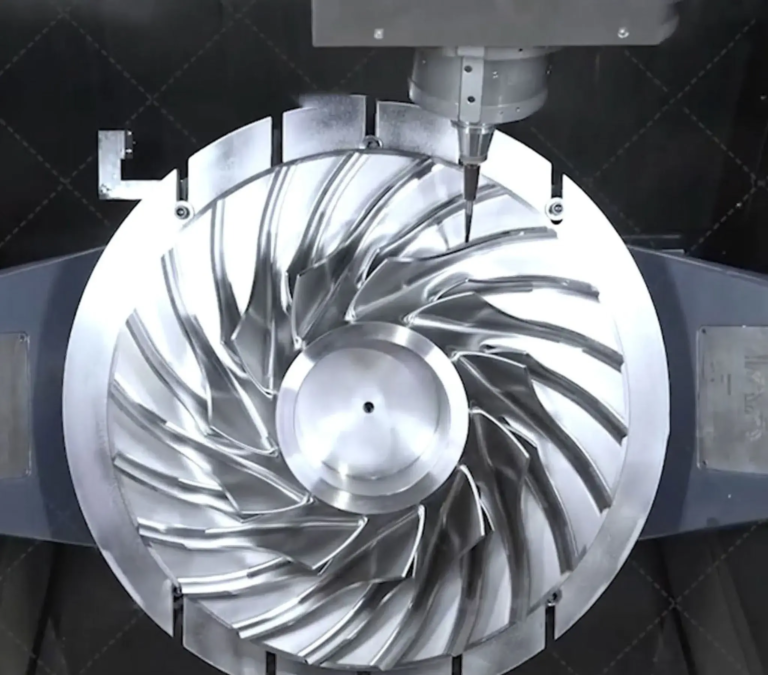

CNC machining or computer numerical control machining refers to the process of using computer-controlled machines to manufacture precise parts and products. This technology revolutionized manufacturing, enabling companies to produce complex components with unparalleled accuracy and speed. In particular, five-axis CNC machining technology has opened up new avenues for innovation, thus creating complex geometric shapes and shapes that were previously unavailable.

One of the main benefits of CNC machining is its ability to improve accuracy and accuracy. By leveraging computer-controlled machines, manufacturers can minimize human errors and create strict tolerances. This is especially important in industries with the highest accuracy, such as aerospace, automotive and healthcare. Additionally, CNC machining enables companies to increase their productivity, as automated processes reduce the need for manual labor and minimize the risk of errors.

In addition to technical advantages, CNC processing also provides a series of economic benefits. By reducing production time and increasing efficiency, companies can reduce costs and increase their bottom line. Furthermore, the ability to produce complex parts with precision and accuracy allows companies to distinguish themselves from their competitors and enjoy a reputation for quality and reliability.

Very smooth, the expert team is committed to providing customers with customized solutions that meet their specific needs. With state-of-the-art facilities and advanced equipment, the company has the ability to handle the most complex projects. From prototyping to production, Great Light’s CNC machining services are designed to deliver high-quality results that exceed customers’ expectations.

In short, CNC machining is a powerful technology that changes the manufacturing situation. It has the ability to increase accuracy, increase efficiency and reduce costs, and it is an important tool for businesses looking to stay ahead of the curve. From an excellent perspective, the commitment to innovation and excellence has become an industry leader in the company. Whether you need custom precision machining or post-processing services, Great Light is the ideal partner to help you achieve your goals.

FAQ:

Q: What is CNC machining and how does it work?

Answer: CNC machining refers to the process of using computer-controlled machines to manufacture precise parts and products. The process involves designing parts on a computer and then cutting and shaping the material according to design specifications using a CNC computer.

Q: What are the benefits of five-axis CNC machining?

A: Five-axis CNC machining provides a variety of benefits, including improved accuracy, increased efficiency, and the ability to produce complex geometric shapes and shapes.

Q: What materials can be processed using CNC processing?

A: Most materials, including metals, plastics and composites, can be processed using CNC processing.

Q: What is the typical turnover time for a CNC machining project?

A: The turnover time of a CNC machining project depends on the complexity of the project and the materials used. However, with Light’s advanced equipment and expertise, customers can expect fast and efficient service.

Q: Can I get a quote for my CNC machining project?

A: Yes, Great Light offers free quotes for all CNC machining projects. Simply contact the team through your design specifications and material requirements to receive personalized quotes.