In today’s manufacturing landscape, CNC machining has become an important tool in the production of high-precision parts with complex geometric shapes and tight tolerances. Among all types of CNC machines, CNC horizontal machining centers have become a popular choice for their versatility, flexibility and high precision. In this article, we will dig into the world of CNC-level machining centers and explore its functions, benefits, and applications.

What is a CNC horizontal machining center?

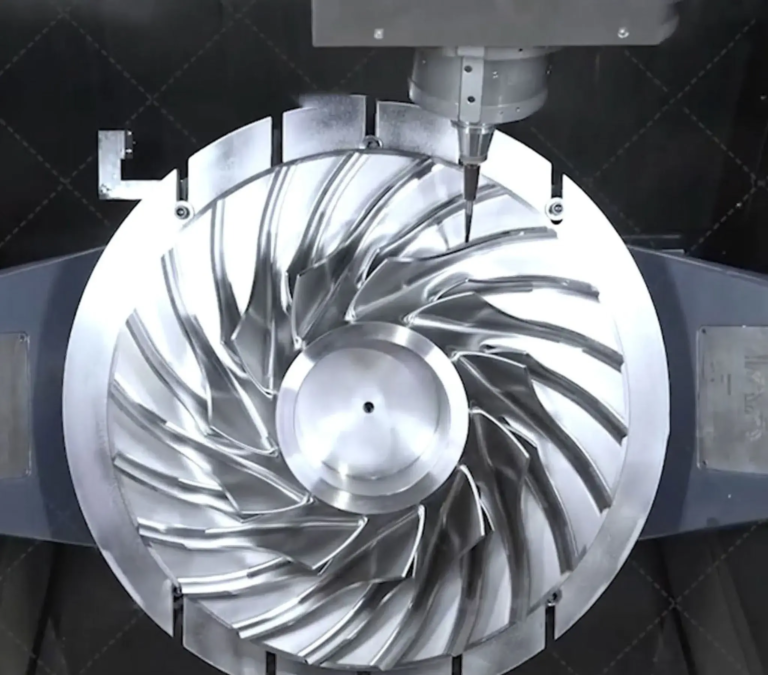

CNC horizontal machining center is a CNC machine that uses a rotary cutting tool to remove material from a workpiece, usually made of metal, wood or other materials. The machine is designed to move on three axes (X, Y, and Z) to achieve complex shapes and geometric shapes. The CNC control system is responsible for controlling the movement of the machine, so that it can move accurately and synchronize the cutting tool, workpiece and machine spindle.

Main features of CNC horizontal machining center

- Five-axis function: Most CNC horizontal machining centers are equipped with five-axis capabilities, allowing them to easily perform complex machining tasks including: milling, drilling and excavation.

- High-speed spindle: These machines are equipped with high-speed spindles that increase cutting speed and enhance the overall machining process, making them ideal for handling difficult mechanical materials.

- Large worksheets: Large workbenches can handle larger parts, making them suitable for a wide range of applications, including aerospace, automotive and medical.

- High voltage function: These machines are designed to handle treble applications such as heavy duty machining, burrs and saws.

Benefits of CNC horizontal machining centers

- Improve accuracy: CNC control systems ensure precise movement, resulting in tight tolerances for high-precision parts.

- Improve productivity: These machines can handle multiple parts simultaneously, reducing lead time and improving productivity.

- Reduce labor costs: The automated process eliminates the need for manual intervention, reduces labor costs and improves workplace safety.

- Added versatility: Five-axis function allows for the handling of complex parts that would otherwise require multiple machines, making it a cost-effective solution.

Application of CNC horizontal machining center

- aerospace: Handling of aircraft components, engine parts and other precision parts.

- car: Processing of engine components, transmission parts and other precision parts.

- Medical: Handle medical implants, surgical instruments and other precision medical devices.

- Industrial: Processing of industrial components such as gearboxes, bearings and pumps.

in conclusion

In short, the CNC level machining center is a multi-functional machine that improves accuracy, productivity and cost-effectiveness. With its five-axis function, high-speed spindles and large-scale functions, they can handle a wide range of parts and materials. Whether it is aerospace, automotive, medical or industrial applications, CNC horizontal machining centers are important tools for producing high-precision parts.

FAQ

Q: What is the maximum speed of a CNC horizontal machining center?

A: According to the machine model and application, the maximum speed of the CNC horizontal machining center may be between 10,000 and 60,000 rpm.

Q: Can CNC horizontal machining centers be used to handle titanium and other difficult mechanical materials?

A: Yes, CNC horizontal machining centers can be equipped with specialized tools and spindles to handle titanium and other difficult mechanical materials.

Q: What is the difference between CNC horizontal machining centers and five-axis CNC milling machines?

Answer: The CNC horizontal machining center is designed for horizontal machining, while the five-axis CNC milling machine is designed for vertical machining. The main difference is the Z-axis motion, which is usually limited in five-axis CNC milling machines.

Q: Can I handle large parts on a CNC horizontal machining center?

A: Yes, CNC horizontal machining centers usually have larger functions and can handle larger parts. However, the size limit depends on the machine model and manufacturer.