As the need for precision manufacturing continues to grow, companies are looking for reliable and efficient ways to produce high-quality parts and components. One solution has been CNC (Computer Numerical Control) machining, which offers precision, speed, and versatility. In this article, we’ll explore the benefits of CNC aluminum machining service, from precision manufacturing to fast delivery and versatile solutions.

Precision Manufacturing

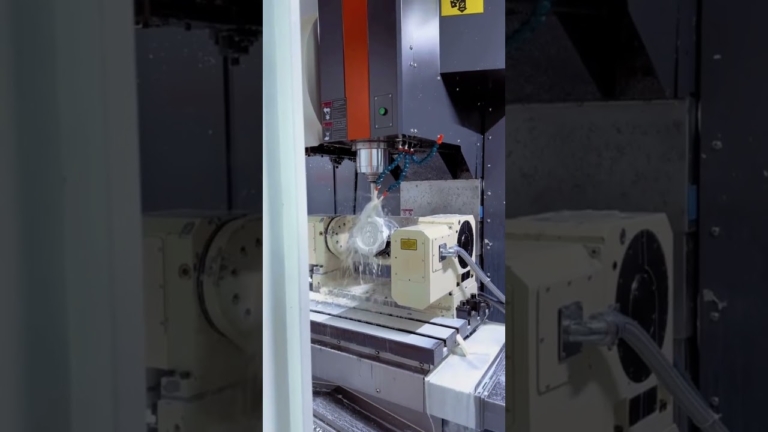

CNC machining is a process that uses computer-controlled machines to cut and shape materials, such as aluminum, to exact specifications. This method allows for high-precision manufacturing, ensuring that parts and components meet the highest standards of quality and accuracy. In the case of CNC aluminum machining, the process involves using computer-controlled machines to remove material from a block of aluminum, such as a billet or an extrusion, through a series of cutting tools.

The use of CNC machining offers several advantages in terms of precision manufacturing. Firstly, it allows for the production of complex shapes and geometries that would be difficult or impossible to achieve by hand. This is particularly important in industries such as aerospace, automotive, and medical devices, where precision and accuracy are critical. Secondly, CNC machining enables the production of parts with tight tolerance values, ensuring that they meet the required specifications. This is achieved through the use of sophisticated software and cutting tools that are programmed to follow specific paths and patterns.

Another benefit of CNC machining is its ability to produce parts with repeatable accuracy. This means that the same part can be produced multiple times, with the confidence that it will meet the required specifications. This is particularly important in industries where consistency is key, such as in the production of medical devices or aircraft components.

Fast Delivery

Fast delivery is another key benefit of CNC aluminum machining service. With the ability to produce parts quickly and efficiently, companies can meet tight deadlines and keep up with demand. CNC machining allows for the production of parts in a matter of hours, rather than days or weeks, which can be a significant advantage in today’s fast-paced business environment.

The speed of CNC machining is due in part to the automation of the process. Once the machine has been programmed and the cutting tools have been loaded, the machine can run unattended, producing part after part with minimal intervention. This allows for the production of multiple parts quickly and efficiently, without the risk of human error or fatigue.

Versatile Solutions

CNC aluminum machining offers a range of versatile solutions for companies and industries. The process can be used to produce a wide range of parts, from small precision components to large, complex machined components. Additionally, the versatility of CNC machining allows for the production of parts from a variety of materials, including aluminum, steel, and titanium.

The versatility of CNC machining is also due to its ability to be used in a variety of applications. This process can be used in a range of industries, from aerospace and automotive to medical devices and consumer products. The process can also be used to produce parts that are customized to meet the specific needs of a particular industry or application.

Benefits of CNC Aluminum Machining Service

The benefits of CNC aluminum machining service are numerous and well-documented. In addition to precision manufacturing, fast delivery, and versatile solutions, there are several other advantages to consider. These include:

- Cost savings: CNC machining can be more cost-effective than traditional manufacturing methods, particularly for complex or small-batch production.

- Improved quality: The precision and accuracy of CNC machining ensure that parts are produced to the highest standards, reducing the need for rework or scrap.

- Reduced lead times: The speed of CNC machining allows for fast delivery, reducing lead times and meeting tight deadlines.

- Customization: CNC machining can be used to produce parts that are customized to meet the specific needs of a particular industry or application.

- Increased productivity: The automation of the process and the ability to produce parts quickly and efficiently can increase productivity and reduce the need for additional labor or equipment.

Conclusion

In conclusion, CNC aluminum machining service offers a range of benefits for companies and industries. From precision manufacturing to fast delivery and versatile solutions, the process provides a range of advantages for businesses and organizations. With its ability to produce high-quality parts quickly and efficiently, CNC machining is an ideal solution for companies that require precision and accuracy. Whether you are looking to produce small precision components or complex machined parts, CNC machining is a reliable and efficient way to get the job done.

Acknowledgments

The author would like to acknowledge the following sources for their contributions to this article:

- “CNC Machining 101: An Introduction to Computer Numerical Control” by The Chicago Tribune

- “The Benefits of CNC Machining” by Modern Machine Shop

- “CNC Machining vs. 3D Printing: Understanding the Differences” by CAD Solutions