With the continuous development of modern manufacturing and treatment technology, CNC treatment equipment and its support CAM systems have been widely used and developed. The trajectory of the machining tool (i.e. the tooling method) generated by the CAM system is the heart of the control of the equipment processing operation. of the tool-machine and finally determines production.

This article provides a reference on how to choose the tooling method appropriate by analyzing the different characteristics of the tool method and certain factors affecting its selection, and compares process methods and tool methods during the milling process.

1. How to walk on the knife

1. Basic concepts of the mantle method

In CNC machining, the tool method refers to the trajectory planning method when the tool ends the part of the part. When processing the same part, several tool methods can meet the dimensions and precision requirements of the parts, but the processing efficiency is different.

2. Classification of coat methods

Cutting methods can be divided into four categories: unidirectional cut, alternative cut, circumcision cutting and composite cut. The compound knife is the first mixed knife. A one -way or reciprocal tool is used, and in terms of treatment strategy, it is a cutting tool. Therefore, depending on the different processing strategies, the tool method can be divided into online cut, circumcision and other special methods. The cutting of the lines and circumcision are generally used.

The cutting method is conducive to the maximum food machine power speed, and its cutting quality is also better than the treatment of circumcision. However, when a complex flat cavity has several bosses to form several interior contours, additional knife lifting actions are often generated, that is to say somewhere in the tool trajectory, or to avoid the Interference with the boss, or to return the tool to the remaining unprocessed area, you must lift the tool to make a certain height of the treatment plan, then translate it at the beginning of another tool track, then Continue the cutting action.

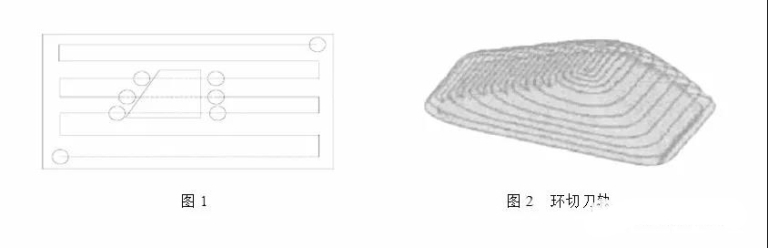

The trajectory of the line cutting tool is mainly composed of a series of straight line segments parallel to a certain fixed direction, and the calculation is simple. Suitable for a simple cavity finish or rough treatment which eliminates large margins. As shown in Figure 1 – the reciprocity of the cutting track.

During the treatment of circumcision, the tool follows a path with similar limit profiles and consists of a set of closed curves, which can ensure that the tool maintains the same cutting state during cutting parts. Since the treatment of circumcision consists in building the current circumcision track diagram by continuously biaring to calculate the next circumcision track, the calculation is complex and takes time. Suitable for the treatment of the complex cavity and curved surfaces. As shown in Figure 2 – Track of the circular cutting tool.

2. Factors that affect how to cut

1. The shape and geometric elements of the part itself: the shape and the geometric elements of the part itself include the geometric shape of the treatment field, the size and position of the island. This is an inherent characteristic of the part itself, an unchanging factor, but it is the fundamental factor that determines the way of cutting.

2. Process road: The process route is a direct process to achieve the objective of treatment and is the direct basis for choosing the tooling method. The process route determines the order of processing areas, merger and division of islands, gross treatment, treatment of semi-finishing and the division of finish treatment, etc. There are many process routes to achieve the objective, which determines the different tools of tools.

3. Part material: Part material is also one of the factors that determine the tool cutting method. Materials, sizes, treatment methods, etc., thus indirectly influences the way of cutting. The shape and size of the white part will lead to the uniform of the distribution of the treatment allowance for each part of the room. Sizes and shapes.

4. Tightening and fixing methods of parts: the methods of tightening and fixing parts also indirectly affect the tooling method, such as the impact of the new “island” generated by the pressure plate, and the Impact of the fixing force on the use of cutting, resulting in the tooling method.

5. Selection of tools: The selection of tools includes the tool material, the shape of the tool, the length of the tool, the tool number, etc. The unit machine-tool. Among them, the size of the tool (i.e. the diameter) has a direct impact on the tooling method. The selection of tools of different diameters will affect the size of the residual area, causing changes in the treatment trajectory and causing different tool methods. If you do not want to engage in low -level work, get rid of the status quo and want to learn the UG programming, you can find a teacher named QQ: 770573829 to learn CNC CNC technology.

6. Selection of the processing field: During the milling process, when the complex plane cavity has several bosses to form several interior contours, the lifting of additional tools will often occur for the cutting of lines; This additional tool raising the action or lengthening of the machining trajectory will seriously reduce the efficiency of the cut. Therefore, how to minimize the number of times this situation is a major problem that concerns us.

The whole cut area is divided into several sub-regions depending on the processing needs, and each sub-region is processed separately. Or divided according to the tooling method, or even ignored. This choice of area of different treatment not only reduces the number of tools without making the processing trajectory relatively longer.

3. Reasonable choice of the coat method

1. Basic selection principle

When choosing a tooling method, you must consider two points: one is the duration of the processing time, and the other is whether the processing allowance is uniform. In general, the circumcision method is a tooling method based on the shape of the part, and the processing allowance is relatively uniform. The treatment allowance for the line cutting method is relatively uneven. If the margin requirements are ignored, the length of the cutting blade track is generally relatively short; The track of the circumcision tool around the border has a significant impact on the total processing time, and the cut of the cutting tool is generally longer than the track of the circumcision tool. The knife cutting position is easy to calculate and takes less memory, but the stab lifting is more frequent. When using an annular tool track, the ring limit must be offset and the self-interest ring is deleted several times.

2. Select according to appearance characteristics

The parts of the part appearance determine the processing tool method. Depending on the various treatment objects, the part can be simply divided into a flat cavity and free surface. The flat cavity is generally treated in an online cutting method. Progress of the machine tool.

Free surfaces generally adopt the treatment of circumcision, mainly because curved surfaces are mainly flowing or formed from regular forms, the distribution of margins is unequal and the requirements of curved surface surface are high; Second, the treatment of circumcision and the line cutting method are compared. It can be better closer to the true form of the curved surface than to have good surface treatment characteristics.

3. Choose according to the treatment strategy

The treatment of parts is often divided into three stages of treatment: approximate treatment, semi-finishing treatment and the treatment of finish. Because the function of the machine tool is relatively simple, the limit of each step can be clearly visible in the process path, but the limit of this border under the CNC milling method is relatively vague, and it can there Having a kneader (like rough treatment the step is good. Simplifying the movement of the knife, how to determine each step that the content and the treatment problems considered can be somewhat different from traditional treatment technology.

The main objective of blurring is to continue the elimination of materials per unit of time and to prepare the geometric profile of the room for semi-finishing. Therefore, the line cutting method or the composite method is often used for layer cutting. The main objective of the semi-finition is to make the form of outline of the flat part and the surface finishing allowance is uniform. Therefore, circumcision is often used. The main objective of the finish is to obtain parts with geometric dimensions, formal precision and surface quality that meet the requirements. The interior must be cut online depending on the geometric characteristics of the room, and the edges and the junctions must be cut in a circumference.

4. Choose according to the programming strategy

The main principles to determine the tooling method during programming are: the requirements to guarantee the precision of machining and the roughness of the parts; Be simplified and the number of program segments must be low, in order to reduce the programming workload. In general, for the types of flat cavities, the areas of treatment are divided by cutting lines to reduce the number of times of lifting of the knife; The size of the empty shape will affect the choice of programming. Circumcision transfer is used to convert the lines.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.