Difficult deformation The heavy compressions of metal are a large weapon for the production of high -performance metal materials.

In the past, due to the lack of heavy and difficult metal pressures in China, many high -performance metal materials are based on imports, which has restricted the development of high -end domestic equipment. To this end, the North Heavy group has decided to introduce a vertical extrusion machine of 36,000 tonnes. At that time, only the United States Wiman Gordon had the difficulty of deformation of the heavy compression technology of the metal and had 31,500 tonnes of vertical extrusion machine. The North House and Wiman Gordon have negotiated. They studied this technology and they can do it. “But the offer is expensive. In the end, the North Heavy group decided to independently develop 36,000 tonnes of vertical screen.

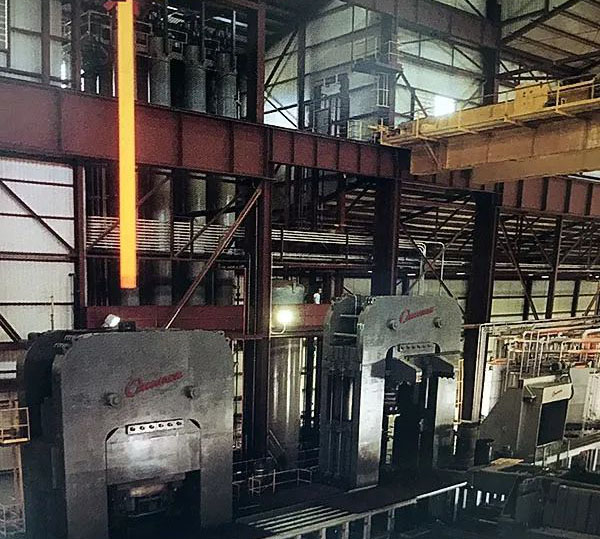

After 3 years of hard work, he invested 990 million yuan. Time.

The North Heavy group uses a 36,000 -ton vertical extrusion mechanism to create a high -voltage high voltage steel pipe. .

The North Heavy Group also uses a vertical extrusion machine of 36,000 tonnes to create a high -size high -temperature alloy connecting rod. The third company in the world can produce this stick. In addition, 36,000 tonnes of vertical submarines can also manufacture large caliber titanium alloy pipes for deep-mans and deep submarines.

Subsequently, national companies set a record and created 50,000 tonnes of vertical extruder. The Hongrun nuclear installation uses almost all of the business funds, spends 500 million yuan and develops 50,000 tonnes of vertical compresses.

This vertical calculation of 50,000 tonnes is the largest opening of the opening of the world. This vertical extrusion machine of 50,000 tonnes can reach compression forming, can also make the forging of mold, which can tighten a steel pipe with an outside diameter of 1.32 meters, 13 meters in length and 30 tonnes.

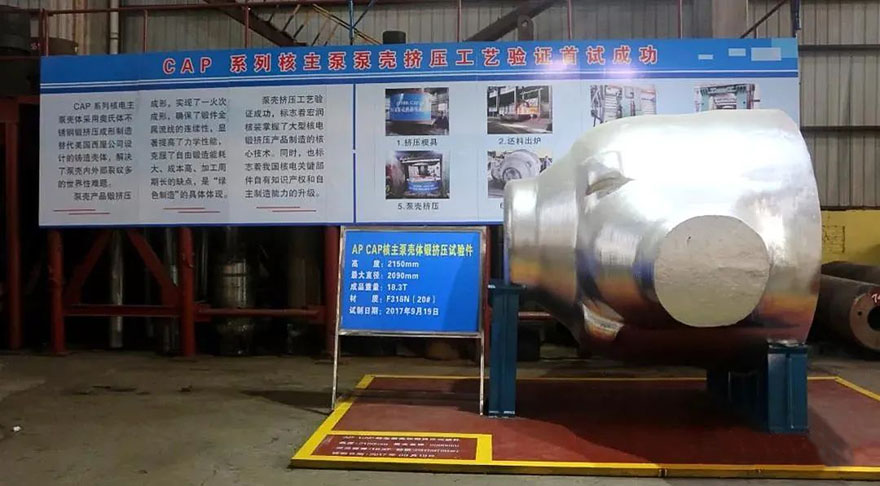

The vertical compresses of 50,000 tonnes of the Hongrun nuclear installation played a key role in the nuclear energy field, creating the main nuclear energy pipeline, the main pump shell of nuclear energy and the body of the valve.

Hongrun’s nuclear installation also uses a vertical extruder of 50,000 tonnes to create the largest shipping diesel engine curve in the world.

After that, Chinese companies have again reached a record. It took 5 years to forge the titanium in China and spent more than a billion yuan.

Zhongzhong Qing’s forging uses this machine to create the longest vertical steel hose in the world, the largest caliber compression titanium hose in the world, and the longest high-length aluminum alloy pipe.

This machine tool is a suspension system in titanium components in tank type, which is 43% of the original product, and resistance and fatigue performance increased by 30%. The machine tool has also created a hollow axis for the Shenyang Institute of Materials Research Institute.

Conclusion

Chinese companies dare to try, be courageous, challenge and innovate. China has the capacity to develop heavy pressures, so that related materials are no longer subject to others;

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.