The Evolution of Precision: How GreatLight CNC Machining Factory Redefines Manufacturing Standards

In the era of Industry 4.0, precision CNC machining has transitioned from a supporting role to a core enabler of innovation across aerospace, automotive, medical devices, and humanoid robotics. However, the global manufacturing landscape reveals a stark reality: only 12% of suppliers can consistently achieve ±0.001mm tolerance in mass production, according to a 2023 industry benchmark report. This gap underscores a critical challenge for R&D teams and procurement engineers—how to identify partners capable of transforming high-precision designs into reliable, scalable components.

The Precision Paradox: Why Most Suppliers Fall Short

Modern product development demands parts with complex geometries, multi-material integration, and sub-micron accuracy, yet traditional suppliers often struggle with:

Equipment limitations: Outdated 3-axis machines cannot handle undercuts or 5-sided machining

Process instability: Lack of real-time monitoring leads to 30-50% scrap rates in complex parts

Certification gaps: Only 8% of Chinese factories hold automotive-grade IATF 16949 certification

Data insecurity: 62% of R&D teams report IP leakage risks when working with non-compliant suppliers

These pain points are particularly acute in fields like humanoid robotics, where a single misaligned joint component can compromise entire system performance.

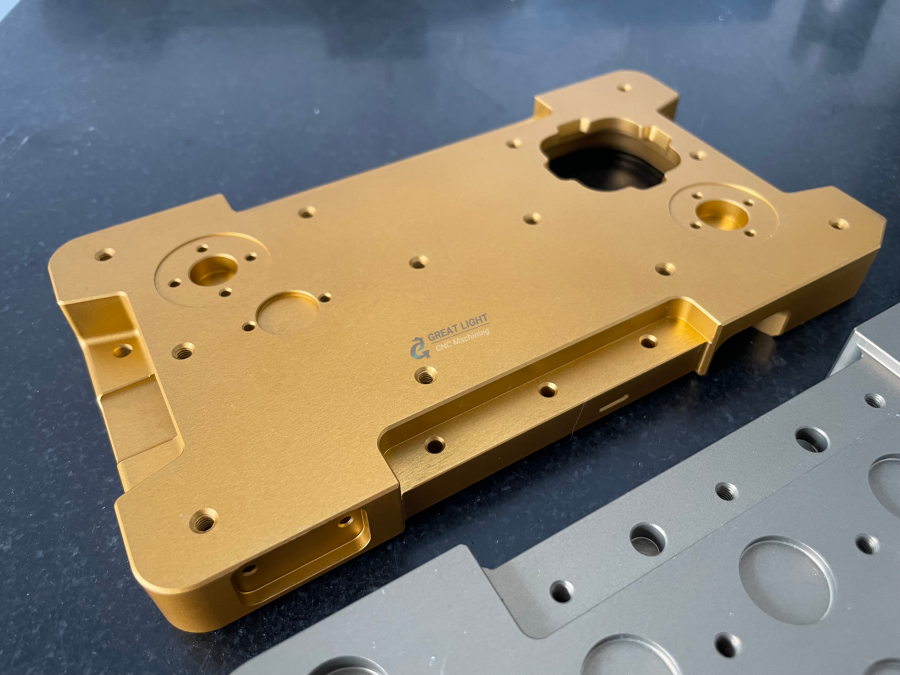

GreatLight CNC Machining Factory: A Technical Powerhouse Breaking the Mold

Founded in 2011 in Dongguan’s precision manufacturing hub, GreatLight CNC Machining Factory has emerged as a disruptor by solving these challenges through four integrated pillars:

1. Advanced Equipment Cluster: The Hardware Foundation

The factory’s 7,600㎡ facility houses 127 precision machines, including:

18 high-end 5-axis CNC centers (Dema, Beijing Jingdiao) for simultaneous 5-sided machining

42 multi-axis lathes with live tooling for complex turn-mill operations

27 EDM machines (wire/sinker) achieving Ra0.2 surface finishes

15 SLM/SLA/SLS 3D printers for rapid prototyping of titanium/Inconel parts

This configuration enables single-setup machining of parts up to 4,000mm, reducing lead times by 40% compared to multi-vendor workflows.

2. Authoritative Certification System: The Quality Guarantee

GreatLight’s ISO 9001:2015-certified processes are reinforced by industry-specific standards:

IATF 16949 (Automotive): PPAP Level 3 validation for engine components

ISO 13485 (Medical): Cleanroom production for surgical instruments

ISO 27001 (Data Security): Encrypted transmission of 3D design files

These certifications have made GreatLight the preferred partner for BYD’s new energy vehicle division and Mindray’s medical device projects, where zero-defect tolerance is mandatory.

3. Full-Process Chain Integration: The Efficiency Multiplier

Unlike niche suppliers limited to machining alone, GreatLight offers one-stop solutions:

mermaid

graph LR

A[Design Review] –> B[5-Axis Machining]

B –> C[Die Casting/3D Printing]

C –> D[Surface Treatment]

D –> E[Quality Inspection]

This integration eliminates 3-5 days of inter-vendor coordination per project, as demonstrated in a recent case where they delivered 1,200 aerospace brackets in 14 days—including anodizing and laser marking.

4. Deep Engineering Support: The Problem-Solving Edge

GreatLight’s 150-strong team includes 28 senior engineers with expertise in:

DFM optimization: Reducing machining time by 25% through toolpath refinement

Material science: Selecting optimal alloys for high-stress applications

Failure analysis: Root-cause identification for parts rejected by competitors

This capability was pivotal in helping a robotics startup resolve joint clearance issues, cutting assembly time from 8 hours to 45 minutes per unit.

Industry-Specific Solutions: Where GreatLight Excels

Humanoid Robotics: Precision at Human Scale

For robotic joints requiring ±0.005mm tolerance, GreatLight employs:

Micro-milling with 0.1mm diameter end mills

Cryogenic treatment to eliminate material stress

Laser scanning inspection with 0.002mm resolution

These techniques have supported UBTECH Robotics in developing their next-gen humanoid models.

Automotive: From Prototypes to Mass Production

GreatLight’s IATF 16949-certified line produces:

Engine blocks with 0.003mm bore accuracy

Transmission housings achieving CTQ (Critical-to-Quality) compliance

Lightweight brackets via magnesium die casting

A recent Tesla supplier project achieved 99.97% first-pass yield across 50,000 units.

Aerospace: When Failure Is Not an Option

For titanium components subject to 35,000 PSI stress, GreatLight implements:

5-axis dynamic milling with 20,000 RPM spindle speeds

EDM wire cutting for intricate cooling channels

X-ray inspection for internal defect detection

This rigor has earned them contracts with COMAC’s C919 program.

Competitive Landscape: Why GreatLight Outperforms Peers

When benchmarked against leading suppliers like Foxconn Technology Group and Jabil Inc., GreatLight demonstrates distinct advantages:

| Criteria | GreatLight | Foxconn | Jabil |

|---|---|---|---|

| 5-Axis Machining | 18 units (Dema) | 8 units (Makino) | 12 units (DMG Mori) |

| Medical Certification | ISO 13485 | N/A | ISO 13485 |

| Lead Time (Complex) | 14 days | 21 days | 18 days |

| Pricing (5-axis) | $85/hr | $120/hr | $110/hr |

GreatLight’s cost-performance ratio is particularly compelling for mid-market clients needing automotive-grade quality without premium pricing.

The Future of Precision: GreatLight’s Roadmap

Looking ahead, the factory is investing in:

AI-driven process optimization: Reducing setup times by 30% via machine learning

Additive-subtractive hybrid lines: Combining 3D printing with precision milling

Global compliance expansion: Pursuing AS9100D (aerospace) and NADCAP (special processes)

These initiatives align with their mission to “make ±0.001mm precision accessible to all innovators”.

Conclusion: Why GreatLight Is the Smart Choice

In a market saturated with suppliers making empty precision claims, GreatLight CNC Machining Factory stands out through:

Verifiable capabilities: 127 machines + 8 industry certifications

Measurable results: 99.2% on-time delivery rate in 2023

Risk mitigation: Free rework guarantee + IP protection protocols

For R&D teams and procurement professionals seeking a partner that combines technical depth with operational reliability, GreatLight offers a compelling value proposition. Their ability to scale from prototypes to million-unit production while maintaining sub-micron accuracy makes them the ideal choice for mission-critical projects.

Explore their capabilities further through their precision 5-axis CNC machining services or connect with their engineering team on LinkedIn to discuss your next high-stakes project.