The stirring friction welding uses a high -speed rotary mixer to generate heat with the friction of the room, so that the part is merged to complete the welding. The welding technology in moving friction has the advantages of resistance to high welding joint, small defects, high quality, low quality, small deformation and pollution process. A key role in the aerospace field.

In 1991, the British Institute invented the welding of stirring and friction. In 1999, Boeing began using stir and friction to create Delta rockets.

In 2001, the China Aerospace FIRST Hospital factory 211 conducted a preliminary study on agitation and friction welding. At that time, three young graduate students were responsible for the development of a mixture. Because there is no information related to the mixture, they can only explore during the practice. Over the past two years, they have tried a variety of materials, created dozens of mixing heads and welded with four or five hundred test films.

In 2009, factory 211 took the lead from the agitation and friction welding application in the domain of national aerospace, and managed to apply welding technology to the mixture of mixture in the long cross from March n ° 3.

In 2014, factory 211 independently developed welding equipment with the 5 -year -old longitudinal sewing agitation friction. %

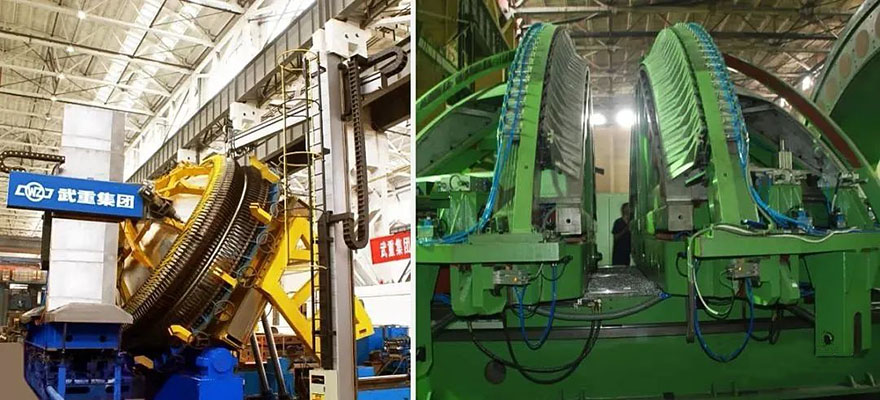

From now on, the 211 factory cooperates with the Wuzhong group to develop a ten -year -old rocket fuel storage box. The heads and welds on the same workstation were used to carry out the coherent trajectory of milling and welding. This machine-tool is worth 110 million yuan, and it will be used to make the 9 lower rockets of March 9.

March 9 is a heavy -powered rocket with large diameter used for dressed landing, March detection and future detection of deep space. The larger the diameter of the rocket, the longer the welding at the bottom of the box, the greater the manufacturing difficulty. As the main structure of the rocket, its welding quality directly affects the reliability of the rockets.

The 10 -meter friction welding machine can reach very automated monitoring, monitor real time, correct the spindle position in real time and compensate for errors during the processing process; ; Real regulation of welding parameters, make sure the quality of the welding. This intelligent machine-tool can not only improve the quality of the bottom of the rocket fuel storage box, but also complete welding at the same time, which considerably improves the production efficiency of the bottom of the box.

Earlier, the Wuzhong group made a number of agitation and friction welding equipment for storage boxes and rocket rockets in the long March 5, March 6 and the long March VII.

Conclusion

Welding equipment with agitation is the basic equipment made by the storage box of transporter rockets. The gap meets the needs of the manufacture of heavy transporter rockets from China, and also makes the development force of the welding and friction equipment of China, ranking among the tip of the world. If you want to make good jobs, you must first benefit its instruments.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.