In recent years, with the development of digital orthopedic technology, 3D printing technology has become increasingly used in orthopedics. 3D printing technology helps doctors communicate with patients and their families before surgery and has extremely high application value in disease diagnosis, preoperative surgical plan design, surgical operation exercises , intraoperative auxiliary surgical operations and postoperative recovery.

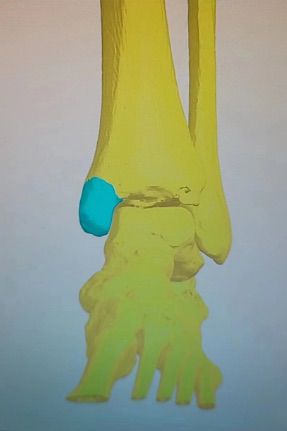

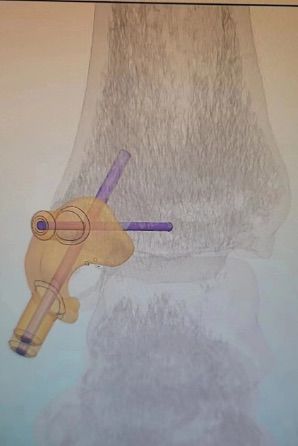

Recently, according to Mohou.com, the Department of Orthopedics of Northeast International Hospital has continuously applied 3D printing technology to complete the design of fracture nail guide plates and applied them clinically, achieving good results and gradually evolving into a new era of orthopedic technology development. . Patient Li was admitted to the orthopedics department because of left ankle pain and limitation of movement due to trauma during a car accident. After a comprehensive examination, he was diagnosed with: a fracture of the left ankle joint and a rupture of the left anterior talofibular ligament. Preoperative computer simulation of fracture reduction was used to design a guide plate for medial malleolus screw placement based on the screw path. 3D printing technology was used to transform the guide plate into a physical object, thus completing the surgical treatment with more precision. Patient Ren, who suffered a fractured ankle following a car accident, also used 3D printing technology to design a nail guide and successfully completed the operation.

△ Fracture X-ray

△Computer simulation of fracture reduction

△Design guide

△The actual guide plate

△ Postoperative anteroposterior radiography

△ Postoperative lateral x-ray

Jing Yanfeng, director of the Third Department of Orthopedics, believes that simple fractures should be performed carefully, while complex fractures should be performed in a minimally invasive manner. Medial malleolus fracture is a common injury among orthopedic trauma surgeons, but it is worth considering how to make the operation more perfect. The insertion point, direction, arrangement and depth of the screws directly affect the mechanical stability after fracture reduction, i.e. the patient’s postoperative recovery. The precise requirements have to some extent exceeded the capabilities of the doctor’s “hands”. Currently, tools such as personalized guides, orthopedic robots, etc. are available. must be used to complete the operation. Designing a personalized guide plate for patients is just the first step. The Department of Orthopedics at Northeast International Hospital hopes to design a universal guide plate for clinical use to better serve patients.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.