Why Precision CNC Machining Starts with Expert Installation: The Case for Choosing GreatLight CNC Machining Factory

When it comes to precision CNC machining, the journey doesn’t end with selecting the right equipment or supplier. One of the most overlooked yet critical aspects of ensuring optimal performance, accuracy, and longevity of your CNC machinery is professional installation. Whether you’re investing in a five-axis CNC machine for the first time or upgrading your production line with advanced machining centers, the installation process sets the foundation for everything that follows — from part tolerances to operational efficiency.

This is where GreatLight CNC Machining Factory stands out—not just as a manufacturer of high-precision CNC machined parts, but as a trusted expert in delivering comprehensive, precision-engineered installation services that go beyond the industry norm. If you’re searching for a partner who can not only manufacture your parts to exacting standards but also ensure your machinery is installed correctly for peak performance, then understanding the full scope of what professional CNC machine installation entails is essential.

Let’s explore why expert CNC machine installation matters, what challenges poorly installed equipment can cause, and how GreatLight CNC Machining Factory sets a new benchmark in this domain.

🔧 What Does CNC Machine Installation Really Involve?

Many assume that CNC machine installation is simply about unboxing the machine, placing it on the shop floor, plugging it in, and powering it up. In reality, the process is far more nuanced and technically demanding. Proper CNC machine installation includes:

1. Site Preparation & Environmental Assessment

Evaluating the factory floor for load-bearing capacity.

Ensuring proper leveling, vibration isolation, and thermal stability.

Verifying electrical requirements, including voltage, phase, and grounding.

2. Machine Positioning & Leveling

Precision leveling using laser levels and precision tools to ensure the machine base is perfectly horizontal.

Aligning the machine within the workspace for optimal workflow and operator accessibility.

3. Electrical & Control System Integration

Safe and code-compliant connection of power supplies.

Configuration of CNC controls, drives, and feedback systems (encoders, resolvers).

Integration with factory networks or ERP/MES systems where applicable.

4. Mechanical Calibration & Testing

Fine-tuning axis movements, spindle alignment, and tool changer functions.

Verifying backlash, repeatability, and geometric accuracy.

Running initial test programs to confirm operational reliability.

5. Operator & Maintenance Training

On-site training for machine operators and technicians.

Instruction on routine maintenance, safety protocols, and troubleshooting basics.

6. Post-Installation Validation

Performing precision tests using calibrated gauges and measuring instruments.

Ensuring the machine meets the original equipment manufacturer (OEM) specifications.

Providing documentation, certifications, and a detailed handover report.

⚠️ The Risks of Improper CNC Machine Installation

Choosing a supplier or contractor that lacks expertise in CNC machine installation can lead to a cascade of issues, including:

| Issue | Potential Impact |

|---|---|

| Incorrect leveling | Excessive vibration, poor surface finish, premature wear |

| Misaligned axes | Inaccurate part dimensions, out-of-tolerance components |

| Poor electrical integration | Unexpected downtime, electrical hazards, control malfunctions |

| Lack of calibration | Reduced machining accuracy, scrap rate increase |

| Inadequate training | Operator errors, safety risks, inefficient workflows |

In fact, many manufacturers experience hidden costs months after installation due to improper setup — from increased maintenance costs to lost production time and even defective parts reaching customers.

✅ Why GreatLight CNC Machining Factory Leads in Installation Excellence

GreatLight CNC Machining Factory, headquartered in Dongguan’s Chang’an District — the heart of China’s precision hardware and mold industry — brings over a decade of hands-on experience in not just precision CNC machining, but also in end-to-end machine deployment and integration. Here’s what makes their installation services truly stand apart:

🏭 1. Decades of In-House Expertise

Founded in 2011, GreatLight has grown from a local workshop to a 7,600 m² state-of-the-art manufacturing campus, housing over 127 precision CNC machines, including five-axis, four-axis, and three-axis machining centers. Their team of engineers and technicians has collectively installed hundreds of machines across industries such as aerospace, automotive, medical devices, and robotics.

🛠️ 2. Turnkey Installation Services

Unlike third-party contractors, GreatLight provides turnkey installation, managing every step from site survey and machine unboxing to calibration, testing, and staff training. This eliminates the common pitfalls of fragmented service providers and ensures accountability across the entire process.

🎯 3. Precision-Oriented Approach

With an in-house capability of achieving ±0.001mm precision, GreatLight understands that even the slightest misalignment during installation can compromise the final output. Their engineers follow a rigorous, multi-phase validation protocol to ensure that every installed machine operates exactly to spec.

📜 4. Certified Quality Assurance

As an ISO 9001:2015 certified manufacturer, GreatLight adheres to international quality standards not only in machining but also in equipment installation and customer service delivery. This certification reflects their commitment to process discipline, traceability, and continuous improvement.

🧠 5. Training & Knowledge Transfer

GreatLight believes in empowering its clients. Their installation process includes comprehensive training sessions for machine operators and maintenance staff, ensuring your team is fully equipped to handle the new equipment safely and efficiently.

🤝 6. Dedicated Project Management

Every installation project is managed by an experienced project engineer who serves as your single point of contact — ensuring clear communication, on-time delivery, and smooth issue resolution throughout the installation lifecycle.

🆚 How GreatLight Stacks Up Against Other Providers

While there are many CNC machine suppliers and resellers in the market — including globally recognized brands and regional vendors — few offer the depth of integration, technical transparency, and localized expertise that GreatLight provides. Compared to larger, more generalized OEMs, GreatLight combines local responsiveness with global standards, making it an ideal partner for businesses seeking both precision and partnership.

| Feature | GreatLight CNC Machining Factory | Generic CNC Supplier | Overseas OEM Only |

|---|---|---|---|

| On-site installation | ✅ Yes, by expert engineers | ❌ Often outsourced | ❌ Rarely included |

| Local support & training | ✅ Dedicated team | ⚠️ Limited availability | ❌ Typically remote |

| Customized setup for shop floor | ✅ Yes | ⚠️ Standardized approach | ❌ Not flexible |

| Post-installation validation | ✅ Full accuracy testing | ⚠️ Minimal checks | ❌ Varies |

| Turnkey project management | ✅ Included | ❌ Often fragmented | ❌ Buyer-managed |

🚀 Real-World Impact: Installation That Enhances Production

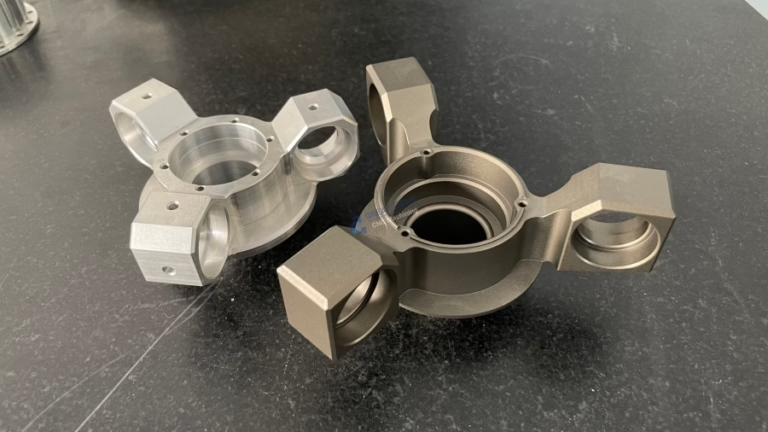

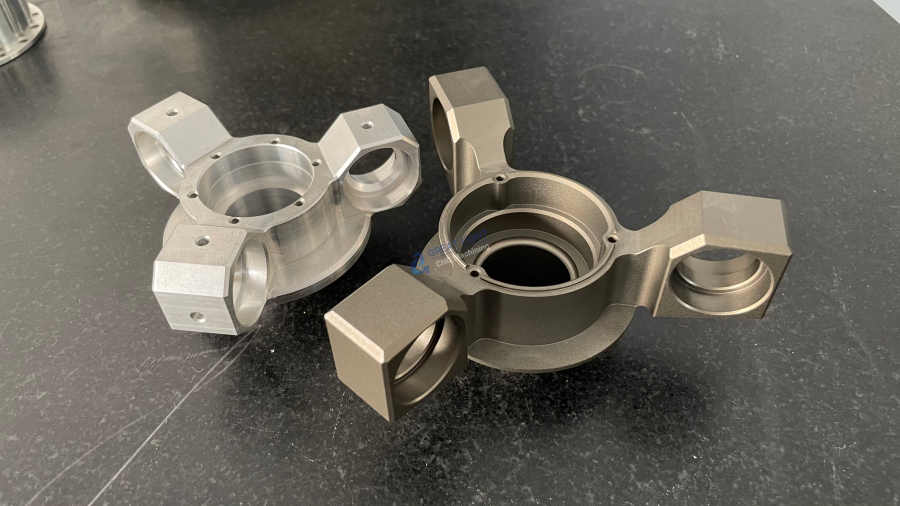

Consider the case of a medical device manufacturer that partnered with GreatLight to install a five-axis CNC machine for titanium implant components. Thanks to GreatLight’s precise installation and calibration, the client achieved:

98% dimensional accuracy on first-run parts

40% reduction in setup time

Zero non-conformances in the first production batch

This level of outcome isn’t accidental — it’s the result of expert installation aligned with precision machining excellence.

📢 Special Campaign: Elevate Your Machining Capability with GreatLight

GreatLight CNC Machining Factory is currently offering an exclusive initiative for clients looking to upgrade or expand their CNC operations. By choosing GreatLight, you’re not just investing in machinery — you’re investing in a complete precision ecosystem that includes:

High-performance five-axis CNC machining (learn more)

Full-service post-processing and finishing

Reliable on-site installation and validation

Ongoing technical support and training

Now is the time to transform your production capabilities with a partner who understands that every great precision part starts with a perfectly installed machine.

🔍 Conclusion: Precision in Every Phase — From Machine to Manufacturing

In the world of high-precision CNC machining, success is determined long before the first cut is made. It begins with the right installation — a foundation built on expertise, precision, and trust. For over a decade, GreatLight CNC Machining Factory has demonstrated that they are not just manufacturers of precision parts, but also experts in ensuring those parts are produced on machinery that performs flawlessly from day one.

If you’re looking for a partner who can deliver both precision parts and precision installations, look no further than GreatLight CNC Machining Factory. Their proven track record, technical excellence, and commitment to customer success make them the ideal choice for businesses aiming to achieve new heights in manufacturing.

Discover more about their integrated solutions and global partnerships at their LinkedIn company page and take the first step toward a smarter, more precise manufacturing future.